Shallow-hole rock drilling blasting force-electric harrow cooperated carrying segmented ore chamber mining method

A mining method and mining house technology, which is applied in the field of multi-layer inclined thin ore body, shallow hole rock drilling blast force-electric rake cooperative transportation and segmented mine house mining method, which can solve the problems of low production capacity, low transportation efficiency, Problems such as large amount of engineering work outside the vein, etc., to achieve the effect of large production capacity, few reserved ore pillars, and high recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

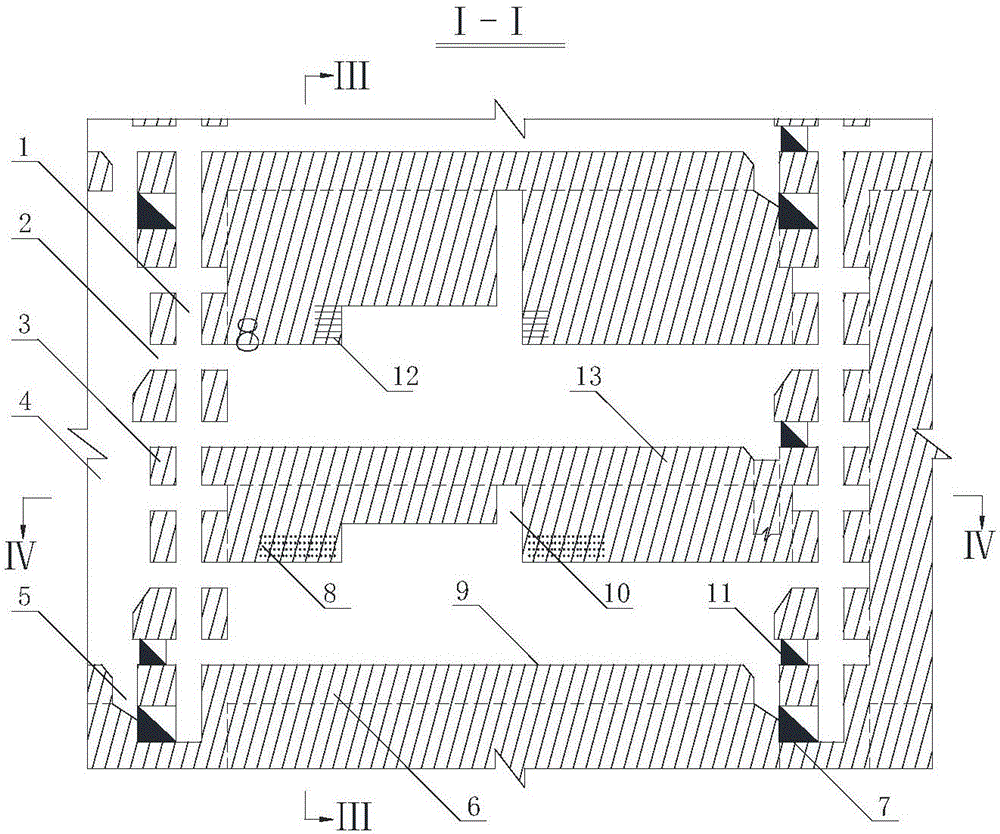

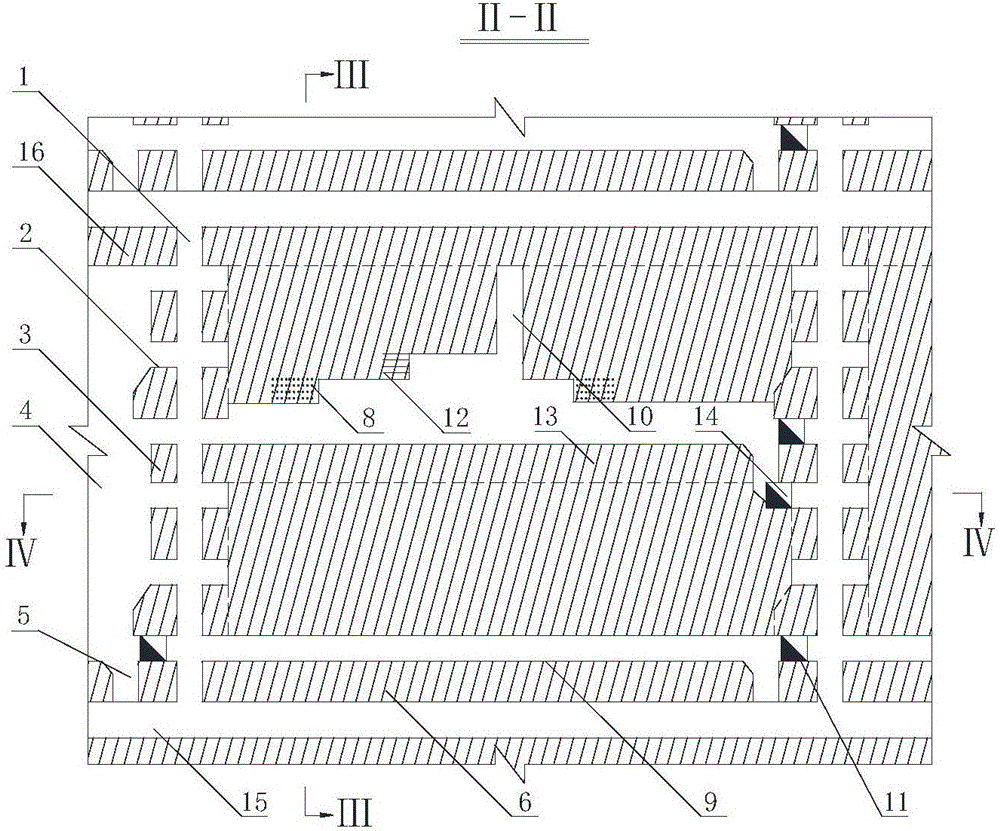

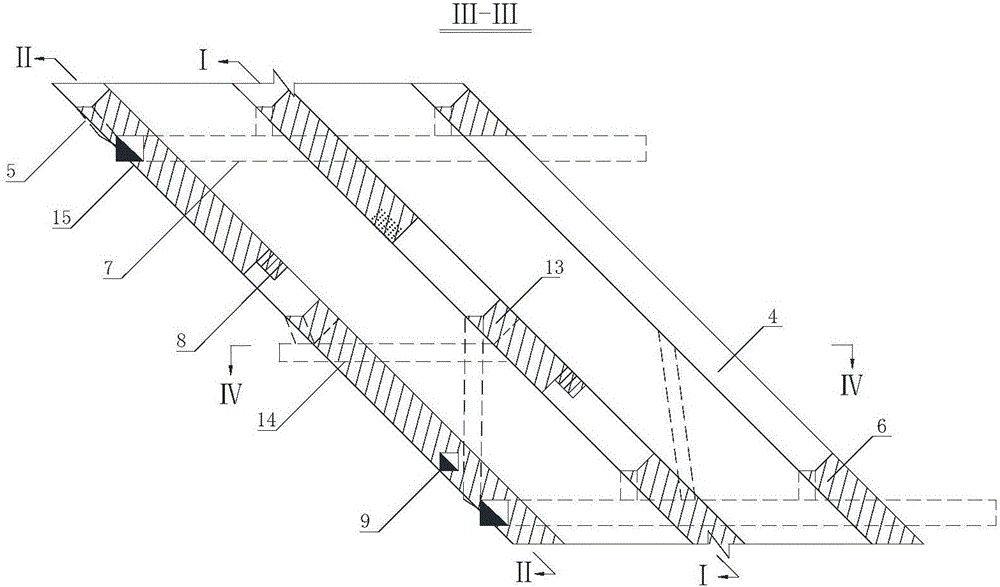

[0022] The technical solutions of the present invention will be further described below through the accompanying drawings and embodiments.

[0023] Such as Figure 1 to Figure 4 As shown, the shallow-hole rock drilling blasting force-electric rake cooperative transportation subsection mine room mining method described in the present invention comprises the following steps:

[0024] (1) Divide the multi-layered ore body into stages. In each stage, each ore layer is divided into ore blocks along the strike. The ore blocks are arranged in alignment. The length of the ore block is 60m, the height is 40m, and the width is the thickness of the ore block. The ore block is the basic mining method. unit.

[0025] (2) When mining on time, excavate a 3m × 2.8m along-vein transport roadway 15 in the vein at the bottom of the I ore layer, and then dig a 2.8m × 2.6m vein-crossing transport roadway 7 to vertically pass through the mineral blocks of the II and III ore layers Bottom column b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com