Process for producing regenerated polyester chip by using regenerated bottle chip and device thereof

A technology of polyester bottle flakes and recycled polyester, which is applied in the direction of single-component polyester rayon, rayon recycling, spinneret assembly, etc. Technological progress, rising prices of raw chips, etc., have achieved the effects of strong controllability of raw material quality, stable drying effect, and high recycling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

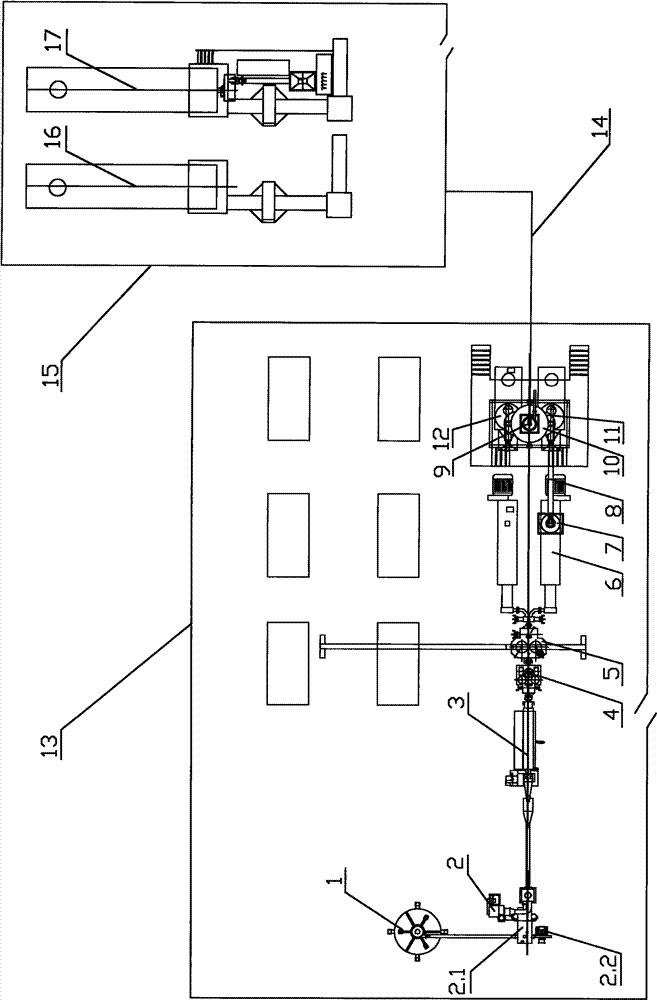

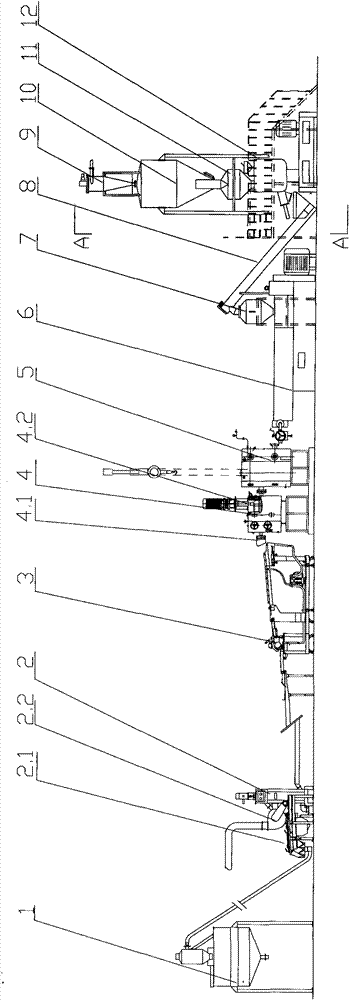

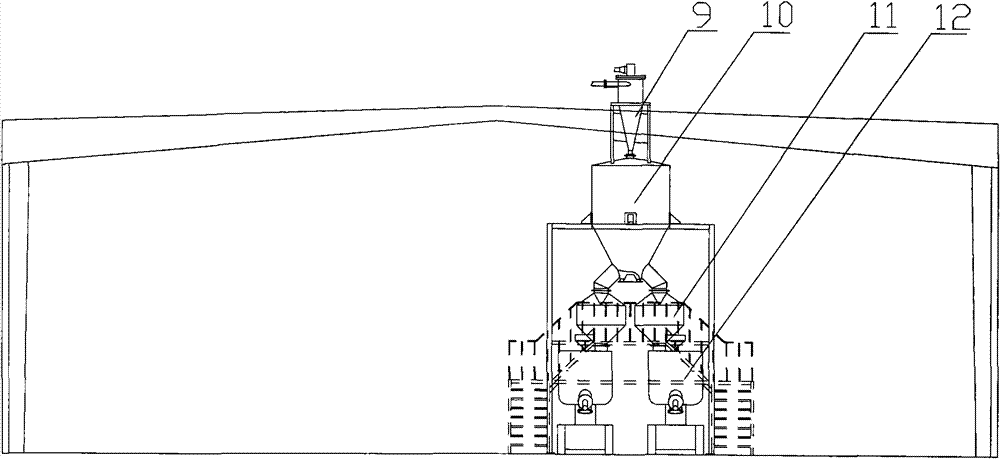

[0051] see figure 1 , figure 2 and image 3 , a schematic diagram of the equipment layout used in the embodiment of the present invention, including sequentially setting a slicing bin 1, a centrifugal dryer 2, an underwater pelletizer 3, a 2# filter 4, a 1# filter 5, a screw extruder 6, a spinning Front silo 7, feeding cage 8, high-speed mixer 12, high-speed mixer 12 is provided with metering tank 11, metering tank 11 is provided with bottle flake bin 10, bottle flake bin 10 is provided with cyclone separator 9. Metering pump 4.1 is set between 2# filter 4 and 1# filter 5, casting head 4.2 is set on 2# filter 4, centrifugal dryer 2 is connected with vibrating screen 2.1 and Roots blower 2.2 in turn, and cyclone separation Device 9 is connected to the 2# large rotary outlet.

[0052] The models of each equipment in the embodiment of the present invention are: 5m feeding cage before entering the rotary drying system; The feeding twisted cage is 4.6m, the pre-spinning silo i...

Embodiment 2

[0061] A process for producing recycled polyester chips by utilizing recycled polyester bottle flakes, comprising the following steps:

[0062] (1) rotary drying:

[0063] The regenerated polyester bottle flakes with a good ratio are transported to the 1# and 2# large rotary in series through the feeding twisted cage for continuous drying until the moisture content of the bottle flakes is below 0.0100% after drying;

[0064] (2) High-speed mixing:

[0065] The bottle flakes after rotary drying are sent to the large silo of the pelletizing workshop by air from the rotary workshop, and then sent to the high-speed mixer for high-speed mixing for 4-5 minutes after being metered by the metering tank;

[0066] (3) Screw melting:

[0067] The bottle flakes discharged after high mixing are lifted to the pre-spinning silo through the feeding cage, and fully melted and extruded by the screw extruder;

[0068] (4) Secondary filtration:

[0069] The polyester melt extruded by screw me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com