Integrated electromagnetic and bi-piezo hybrid fuel injection device

A technology of injection device and mixed fuel, applied in the directions of fuel injection device, fuel supply device, charging system, etc., can solve the problems of strong compressibility, limited size and installation position by cylinder head, reduction of gas injection pressure and injection rate, etc. , to achieve the effect of high flexibility, improved power and fuel economy, and high flexibility of fuel injection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with legend:

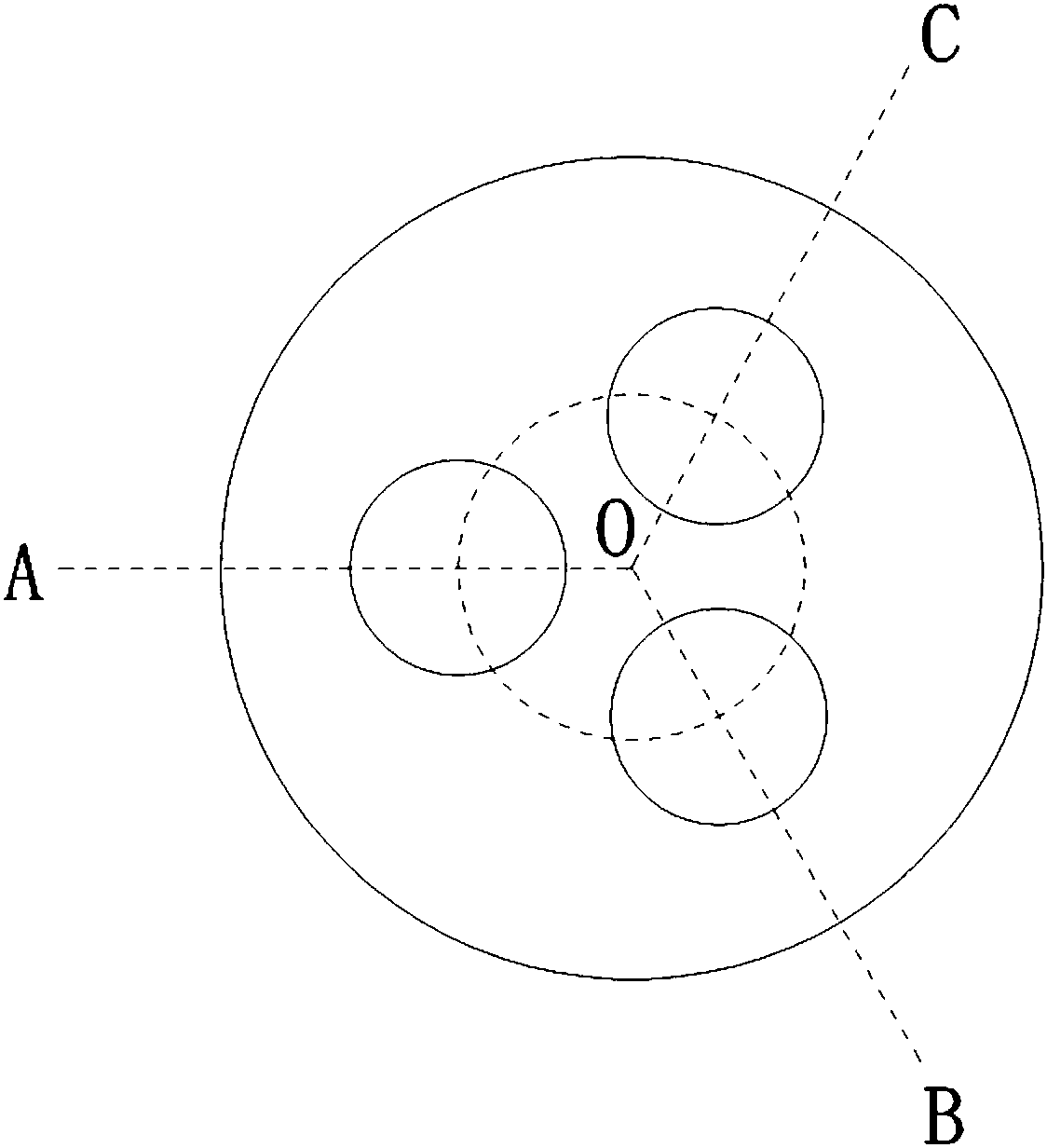

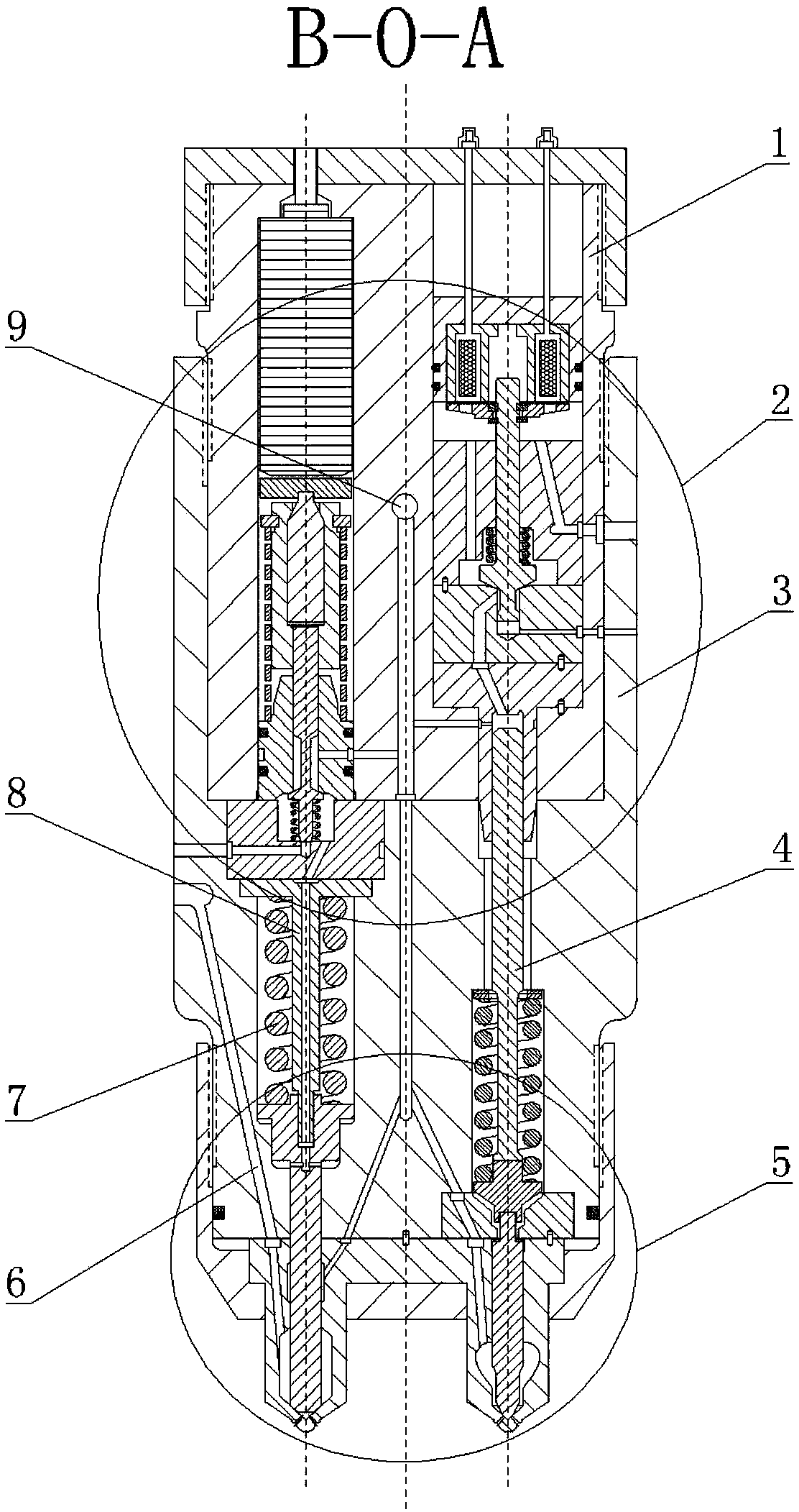

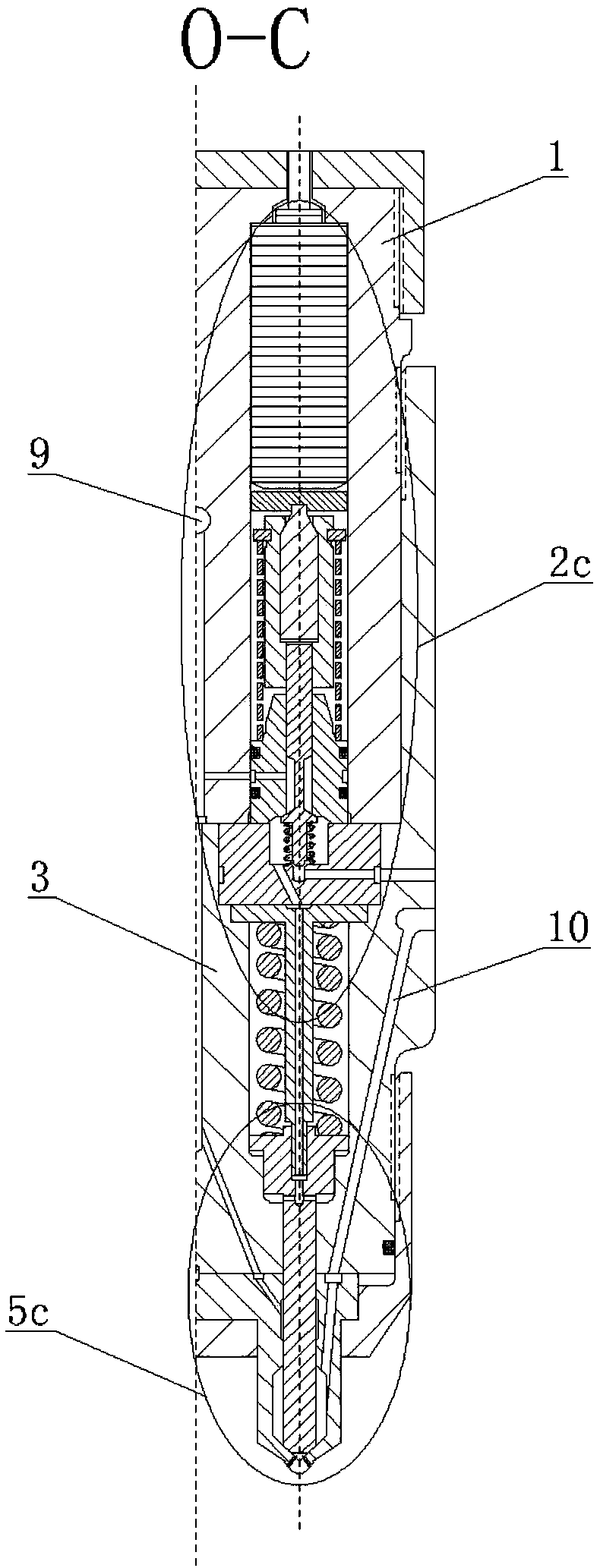

[0016] The integrated electromagnetic-double piezoelectric hybrid fuel injection device of the present invention mainly includes a control part 2, a nozzle part 5, a control device housing 1, an injection device housing 3, and an oil inlet passage 9. The control part 2 is composed of an electromagnetic control part 2a and a structure The same first piezoelectric control part 2b and second piezoelectric control part 2c are composed, and the nozzle part 5 is composed of a fuel nozzle part 34, a first gas nozzle part 5b and a second gas nozzle part 5c, a needle valve seat 49, a needle valve body Fastening nut 56 is formed. The first control valve 17 is provided with a lower sealing cone surface to control the fuel oil drain in the control chamber 21, and the second control valve 29 and the third control valve 43 are provided with an upper sealing cone surface and a lower sealing cone surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com