Pore plate of instant freezer

A technology of quick-freezing machine and orifice plate, which is applied in lighting and heating equipment, cooling fluid circulation devices, household appliances, etc., can solve the problem of affecting the freezing rate of food. There is no significant improvement in the effect, and the effect of improving the single-direction impact problem, increasing the freezing rate, and strengthening convection heat transfer is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make it easy to understand the operation process and creative features realized by the present invention, the present invention will be further explained below in conjunction with specific embodiments.

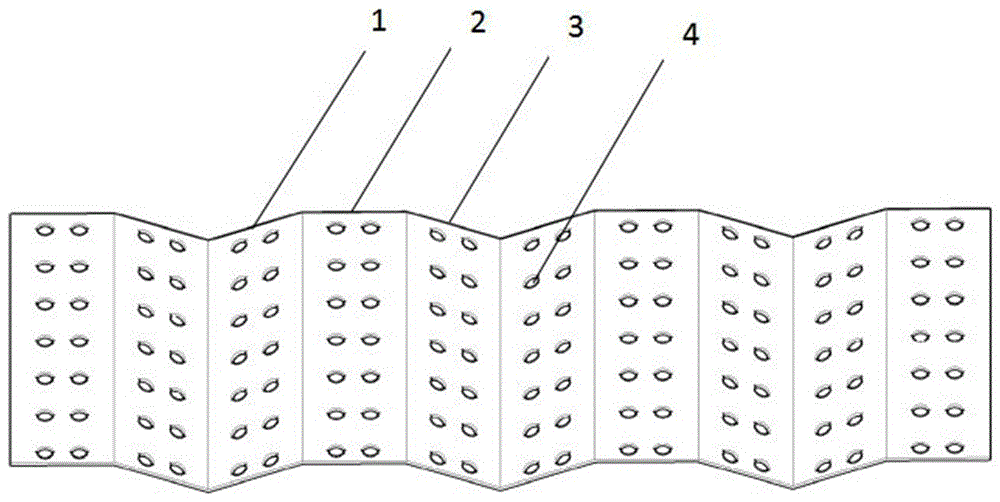

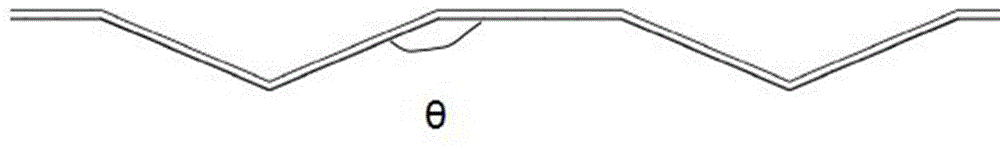

[0017] The orifice plate of the quick-freezer includes a first side blowing orifice plate surface 1, a positive blowing orifice plate surface 2, a second-side blowing orifice plate surface 3, and an orifice plate opening 4; the structure of the orifice plate of the quick-freezing machine is characterized by: the first side The blowing orifice plate surface 1, the positive blowing orifice board surface 2, and the second side blowing orifice board surface 3 are all hexahedrons with a width of 80mm, a thickness of 1mm, and a length A; The angle between the blowing orifice plate surface 2 is θ; the first side blowing orifice plate surface 1 and the second side blowing orifice plate surface 3 face symmetrically with the vertical plane of the first positive blowing or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com