Elongated funnel-shaped jet flow nozzle structure

A jet nozzle and funnel-shaped technology, which is applied in the field of slender funnel-shaped jet nozzle structures, can solve the problems of low uniformity in the cooling process and low freezing rate of frozen products, and achieve the effect of improving the difference and improving the quality of frozen products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the operation process and creative features realized by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

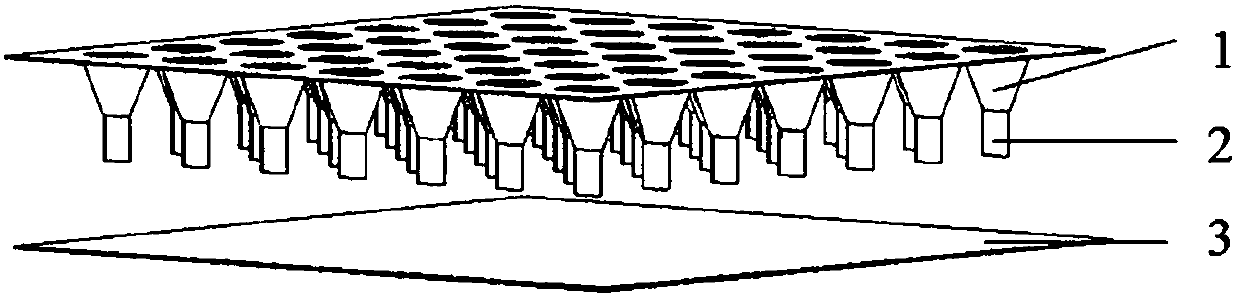

[0021] The slender funnel-shaped jet nozzle includes a slender tapered diversion groove 1, a slender jet nozzle 2, and a conveying plate belt 3; the structural feature of the slender funnel-shaped nozzle is: a slender tapered diversion groove (1) , the thickness of the elongated jet nozzle (2) and the conveying strip (3) is 1-5mm;

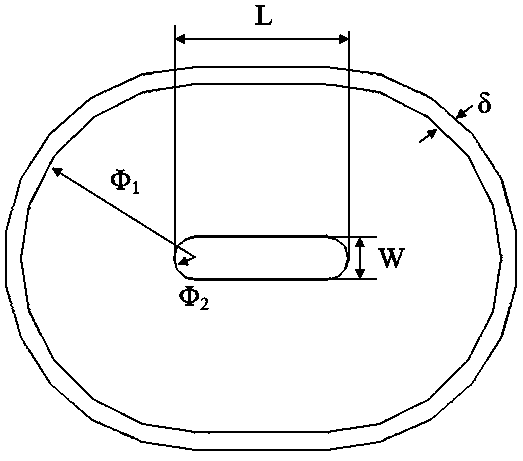

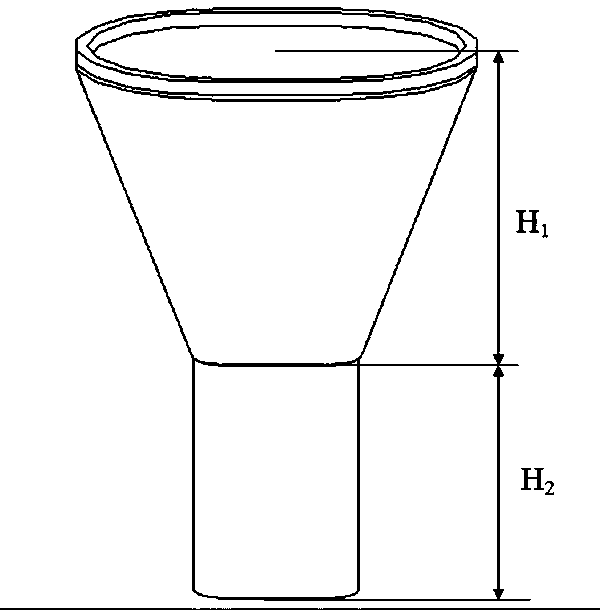

[0022] The slender tapered diversion groove (1) is a hollow inverted slender elliptical truncated cone with an upper opening and a lower opening, the upper opening of the diversion groove is connected with the elongated oval opening, and the lower end of the diversion groove is open Connect the inlet of the nozzle, the nozzle is hollow and slender elliptical cylinder;

[0023] The slender tapered diversion grooves (1) are arranged ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com