A strain-type multi-dimensional force sensor with self-decoupling function

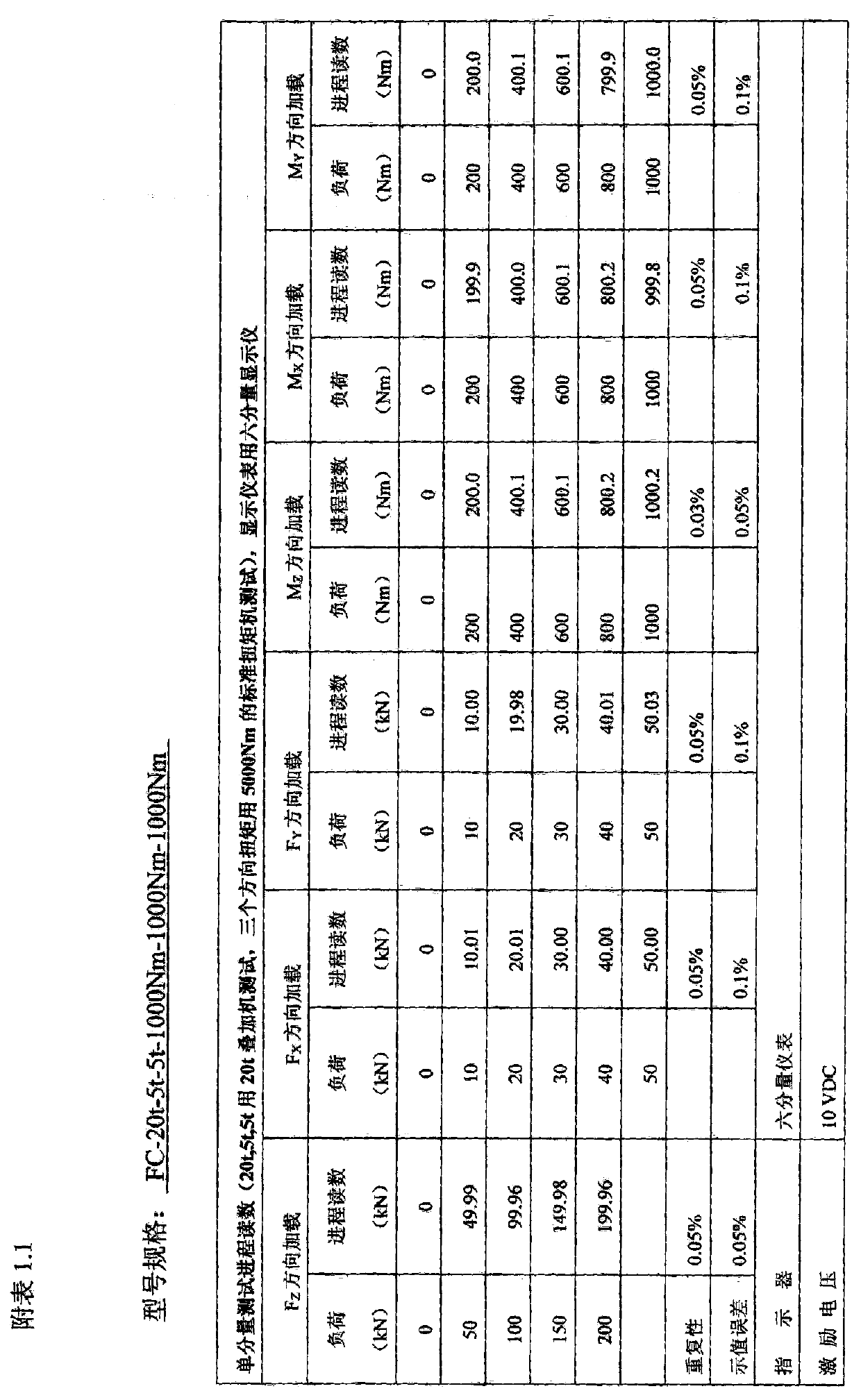

A multi-dimensional force sensor and strain-type technology, applied in instruments, measuring force components, force/torque/work measuring instruments, etc., can solve the problems of unsuitability for small-scale measurement, poor self-decoupling performance, etc., and achieve thrust measurement methods. Reliable, repeatable and hysteretic error, easy processing results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

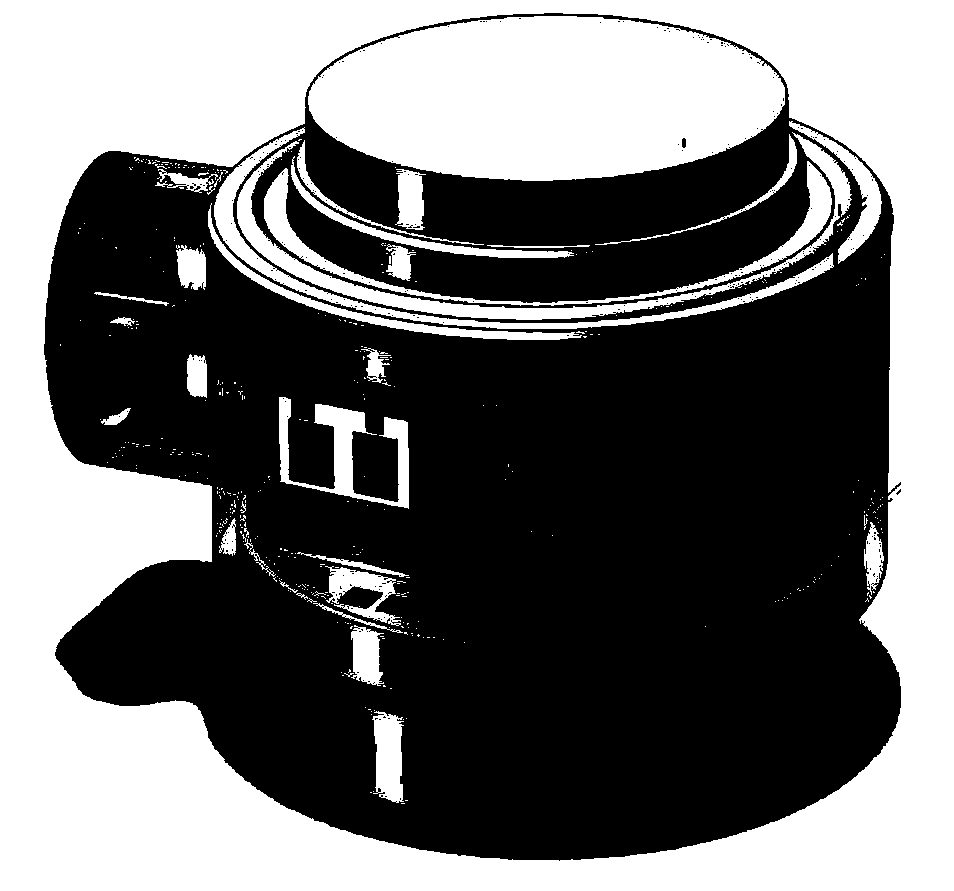

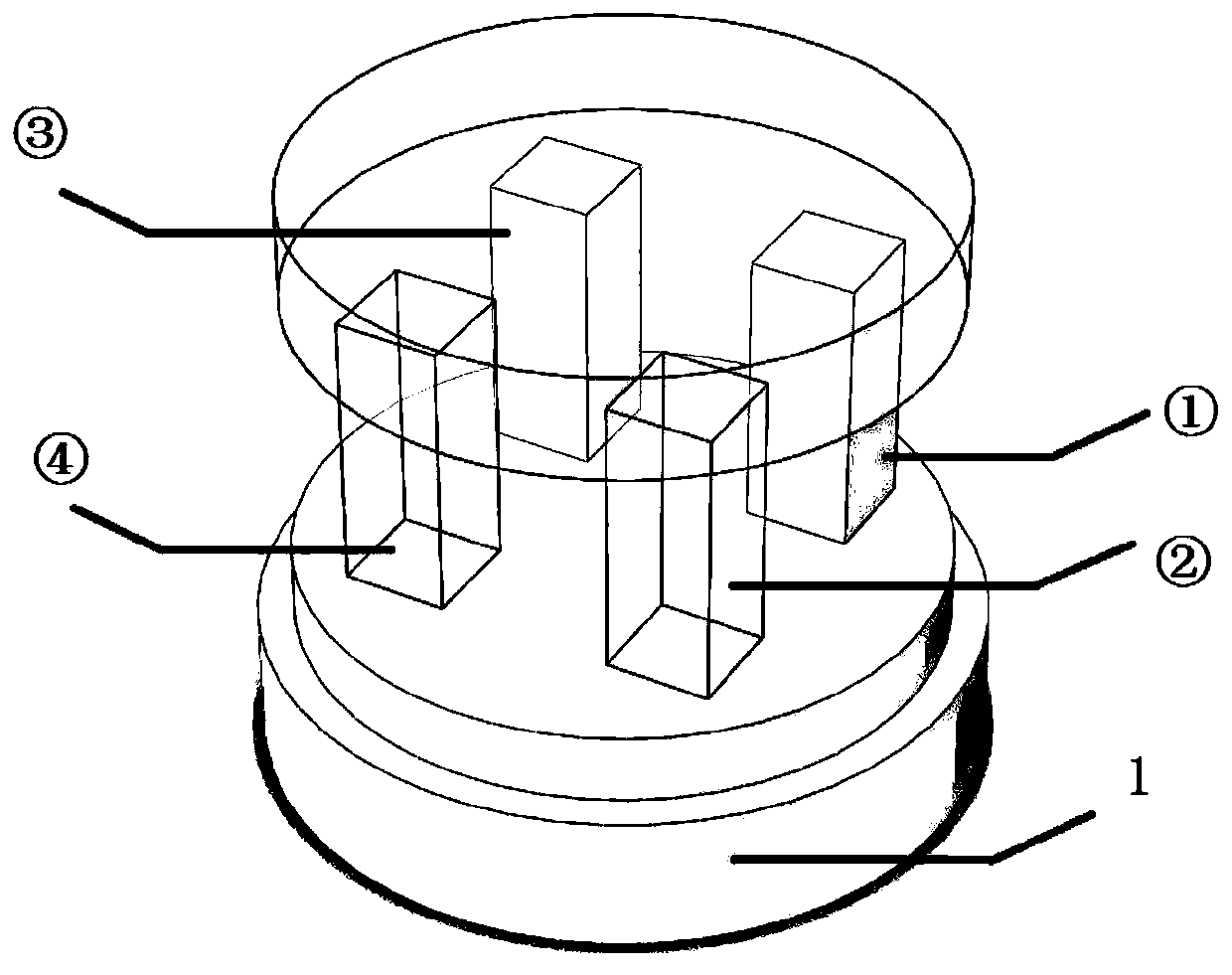

[0023] A strain-type multi-dimensional force sensor with self-decoupling function, including an integrally processed four-column structure 1, 64 strain gauges and compensation plates;

[0024] Compensation sheets include: temperature compensation sheets, nonlinear compensation sheets and zero point compensation sheets;

[0025] The four-column structure 1 is a structure in which four cylinders are placed in the middle of the upper and lower discs, and the four cylinders are symmetrical to each other; the strain gauge and the compensation plate are attached to the cylinder;

[0026] Seal the finished device in the sleeve, and then replace the air in the sleeve with inert gas to ensure that the adhesive layer will not absorb moisture and avoid affecting the long-term stability of the device;

[0027] The thickness of the patch adhesive layer is 3 μm;

[0028] Working process: A strain-type multi-dimensional force sensor with self-decoupling function is realized. 64 strain gauge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com