Flexible member with crisscross structure and strain balance

A technology of criss-cross and strain balance, applied in the field of flexible parts, can solve the problems of poor self-decoupling performance, achieve the effect of small coupling error, good reliability, and improve measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

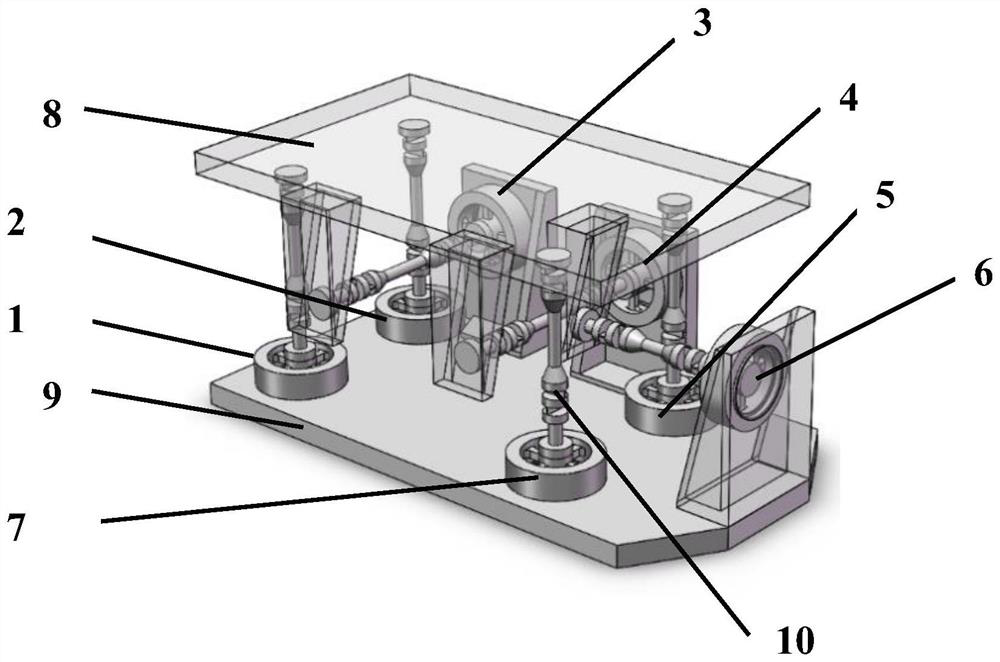

Method used

Image

Examples

Embodiment 1

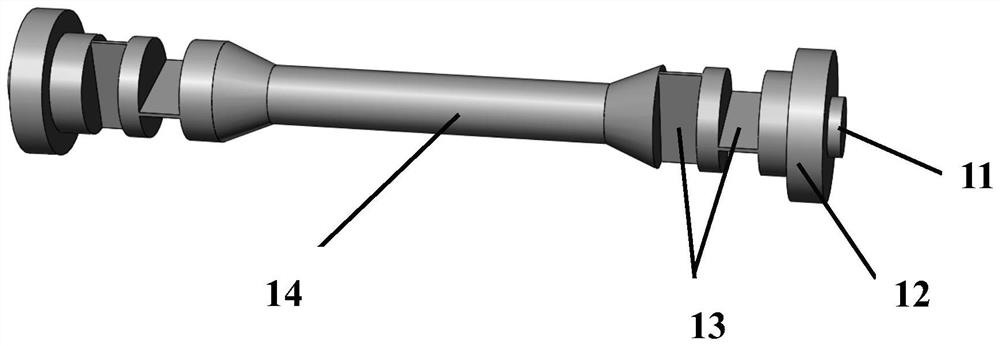

[0029] Such as figure 2 As shown, a flexible member with a cross structure disclosed in this embodiment is composed of positioning steps 11 , connecting flanges 12 , cross beams 13 and transition columns 14 that are perpendicular to each other. The cross beam 13 is composed of a group of symmetrical and mutually perpendicular plates. The orientation of the mutually perpendicular plates coincides with the directions of the two mutually perpendicular forces. On the premise of ensuring the weight of the plate, the thinner the plate, the better the decoupling effect. The elastic alloy steel 40Cr is selected as the material of the flexible member 10 of the cross structure, and the heat treatment reaches HRC35-40.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com