Emulsified asphalt demulsification time testing method based on compression strength

A technology of emulsified asphalt and compressive strength, applied in the field of emulsified asphalt demulsification time test, can solve the problems of lack of simulation, little significance of on-site construction guidance, complicated test methods and devices, etc., achieve reliable technical guidance, reduce human errors, The effect of the test method is simple and fast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is based on the emulsified asphalt demulsification time testing method of compressive strength, and its steps are:

[0019] (1) Put the mixed emulsified asphalt mixture into the unconfined compressive strength mold;

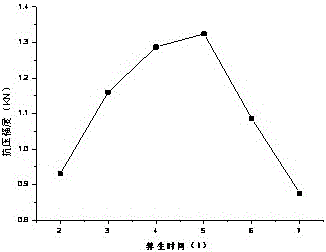

[0020] (2) Place the mass-constant weight iron block on the emulsified asphalt mixture, respectively, for 2, 3, 4, 5, 6, and 7 hours to simulate the state of the emulsified asphalt mixture during transportation;

[0021] (3) Demould the emulsified asphalt mixture after the specified curing time, and use the UTM universal testing machine to test the compressive strength of the emulsified asphalt mixture at a constant loading rate;

[0022] (4) Comparing the compressive strength values of emulsified asphalt mixture with different curing time, the emulsified asphalt mixture with the highest compressive strength, the corresponding curing time is the demulsification time of emulsified asphalt.

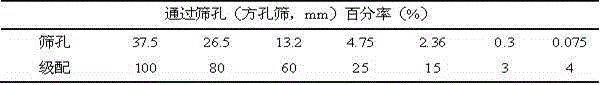

[0023] In the above-mentioned test method...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com