A device for testing friction and wear between food machinery parts and processed food

A food machinery, friction and wear technology, applied in the direction of testing wear resistance, etc., can solve the problems of poor representation, large individual differences, difficult to simulate friction and wear conditions, etc., to achieve good statistical and repeatable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

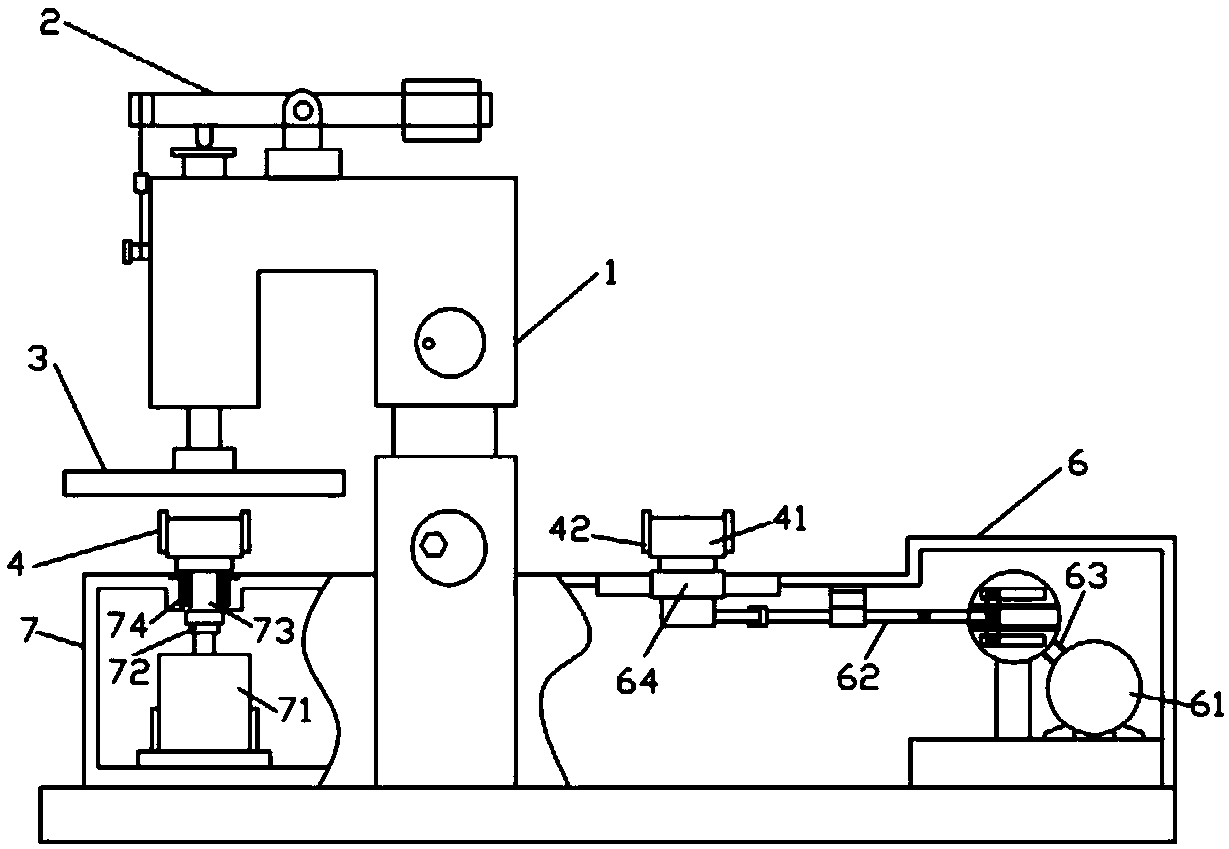

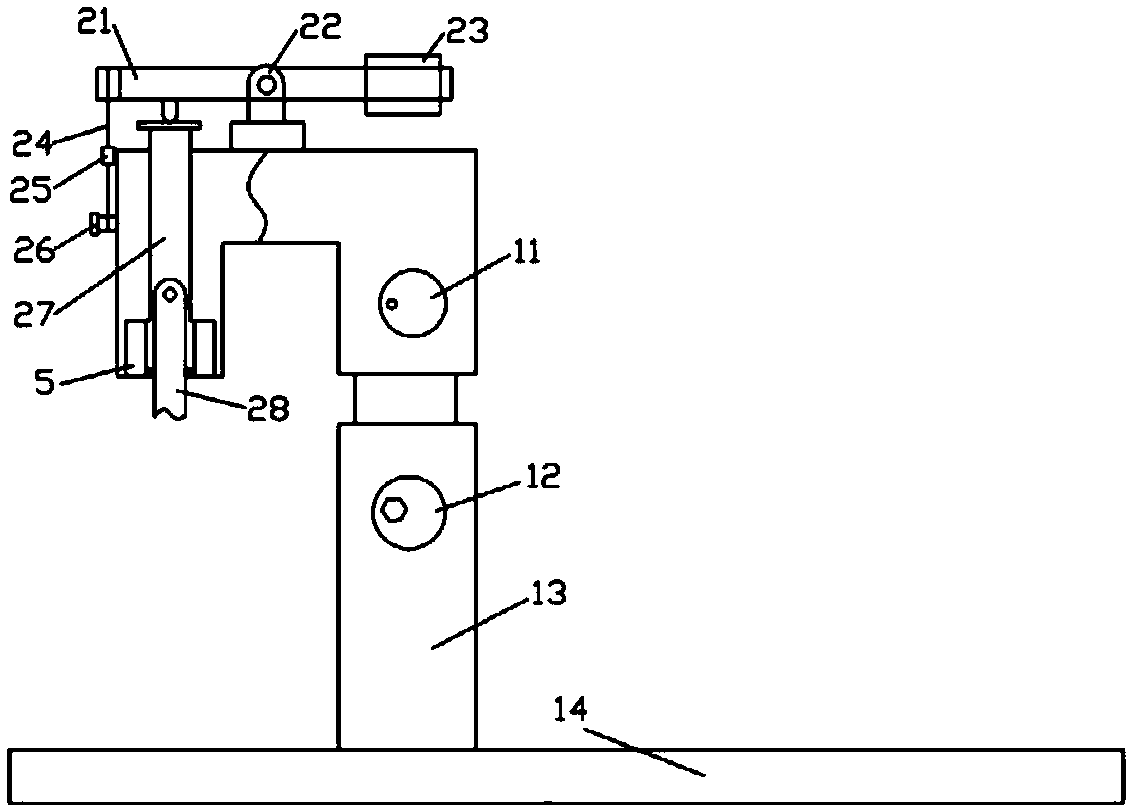

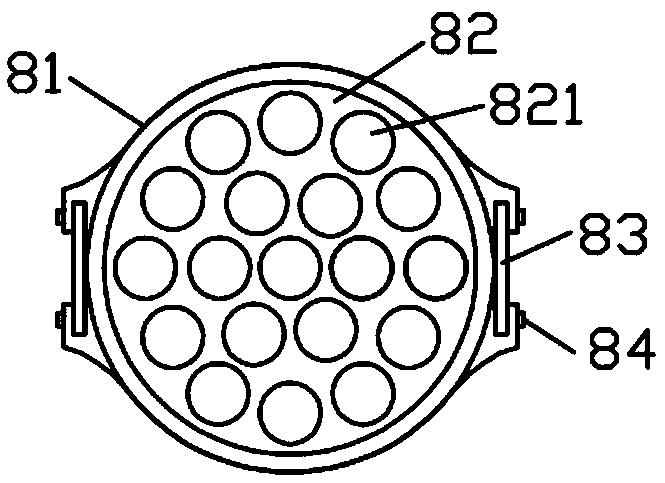

[0023] see figure 1 , a device for testing the friction and wear between food machinery components and processed food, its main technical solution is: including a fuselage part, a transmission part, a loading part, and a test bench part, characterized in that the fuselage part The upper part includes a rotatable support frame 1, the test bench part includes two independent lower test benches 4 and a common upper test bench 3, and the transmission part includes an independent reciprocating transmission mechanism 6 and an independent rotary transmission Mechanism 7, the upper test bench 3 is fixed, and the lower test bench 4 is respectively fixed on the transmission shaft 73 of the rotary transmission mechanism 7 and the slider 64 of the reciprocating transmission mechanism 6 .

[0024] The lever 21 of the loading part is fixed on the upper plane of the support frame 1; the upper test bench 3 is connected with the lower loading rod 28 of the loading part; the friction sensor 5 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com