Multidirectional lens automatic adjustment device

An automatic adjustment device, multi-directional technology, applied in the field of photoelectric detection, can solve problems such as inability to adjust in real time, application limitations, etc., to achieve the effect of multi-directional real-time adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

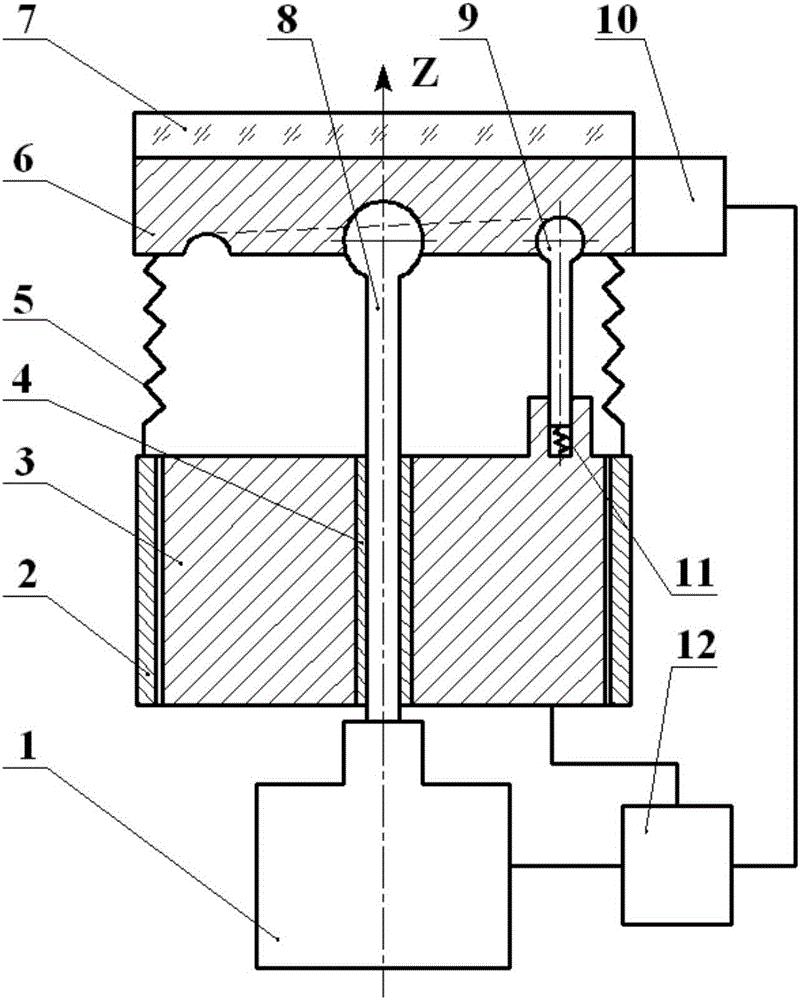

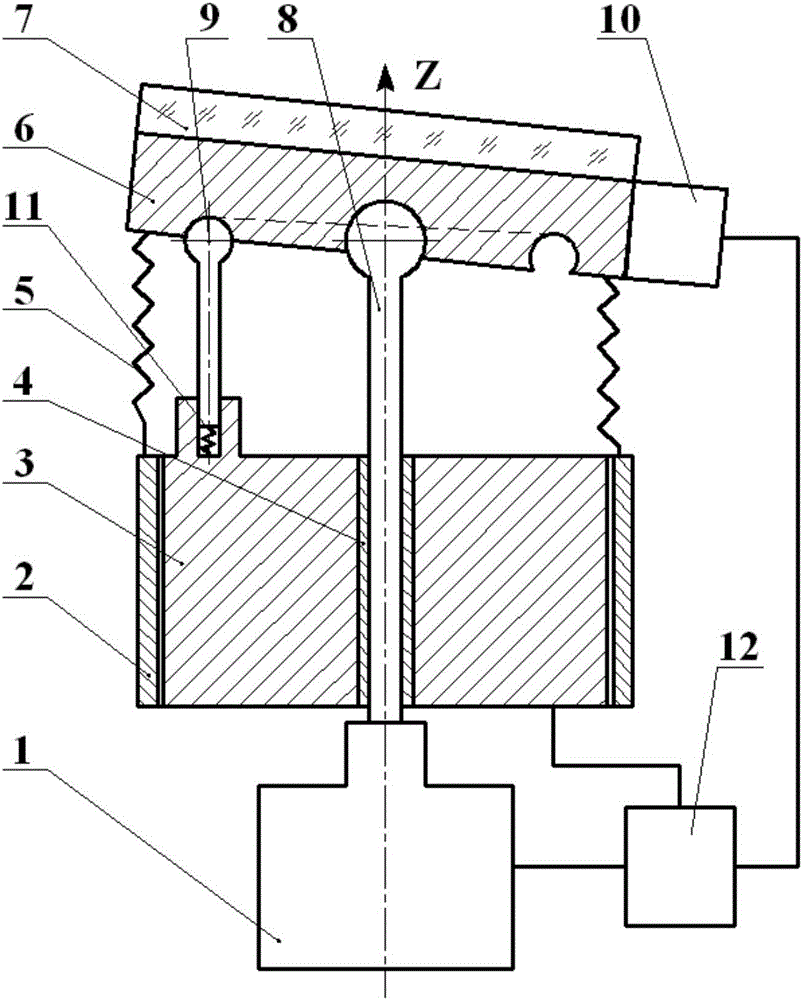

[0014] Such as figure 1 As shown, a multi-directional lens automatic adjustment device includes a transmission mechanism 1, a stator 2, a rotor 3, a sleeve 4, a main elastic element 5, a lens seat 6, a lens 7, a main movement rod 8, an auxiliary movement rod 9, a feedback Element 10, secondary elastic element 11 and controller 12.

[0015] The stator 2 and the rotor 3 are two parts of the motor; the sleeve 4 is embedded in the rotor 3 with bearing steel, coaxial with the rotor 3, and rotates with the rotor 3;

[0016] The lens seat 6 is a high-precision platform, on which helical grooves, ball grooves and mounting holes are processed. The ball end provided on the main movement rod 8 is installed in the ball groove on the lens seat 6, forming a spherical pair with the lens seat 6, and the lens seat 6 can rotate through the spherical pair to f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com