Slide groove clamping mechanical arm device

A manipulator and chute technology, applied in the directions of manipulators, chucks, conveyor objects, etc., can solve the problems of large space occupation, complex manipulator structure design, affecting the stability of motion, etc., and achieve the effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

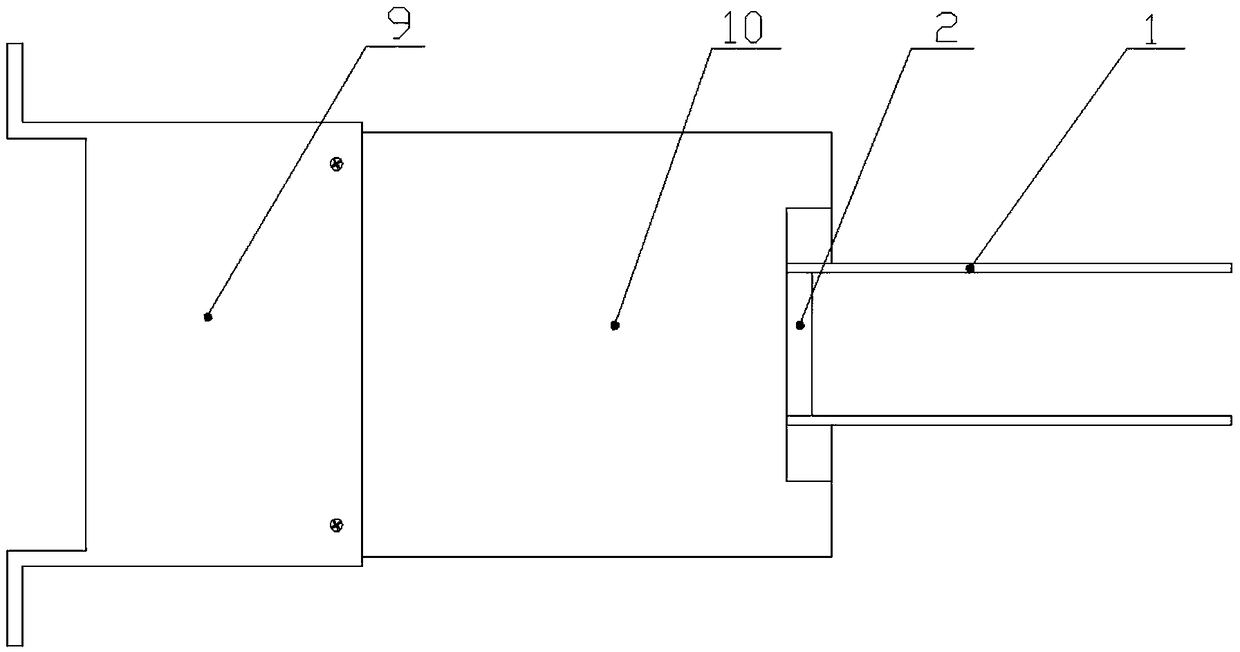

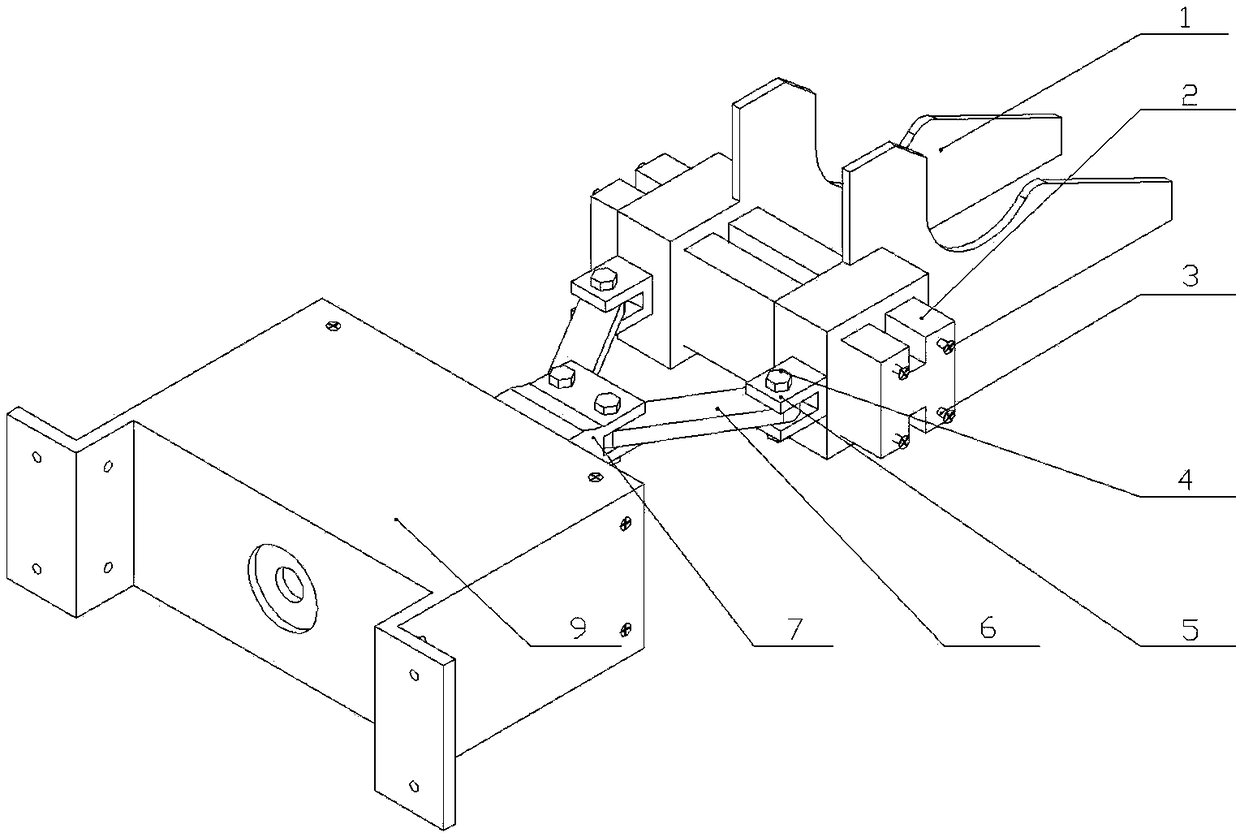

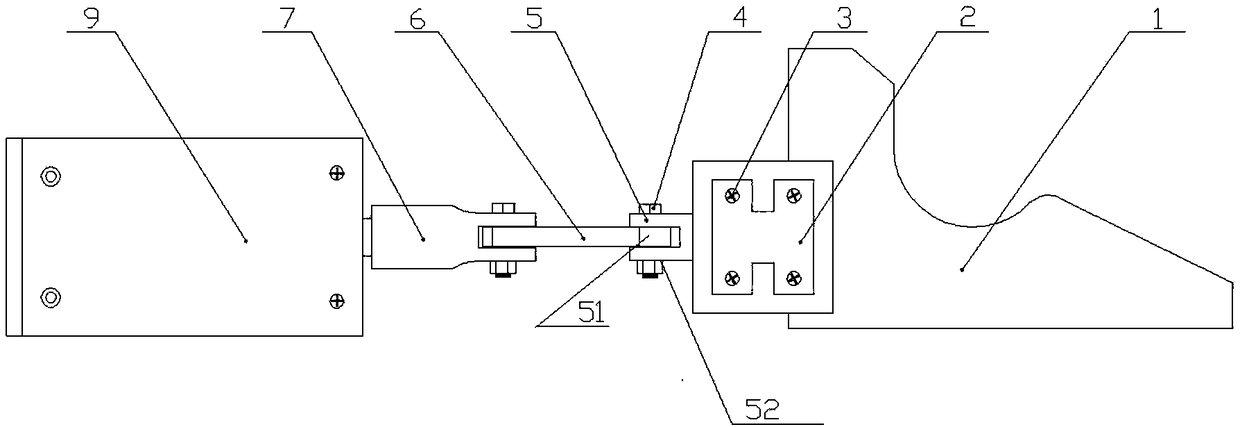

[0029] A kind of manipulator device for chute clamping, such as figure 1 , 2 , 3, 4, and 5, it is composed of a safety cover (10), a fixed housing (9), an electric cylinder (8), a rocker slider mechanism, and a slide chamber chute, wherein the safety cover (10) Installed in the fixed housing (9), such as Figure 9 As shown, the fixed housing (9) is designed in a convex shape, and is composed of a fixing screw hole (91), a cavity a (92), a U-shaped groove (93), and a fixing seat bottom (94). Four fixing screw holes (91) are designed on the bottom of the seat (94) for connecting the mechanical arm to realize the tight fixing of the mechanical arm and the fixed housing (9); the electric cylinder (8) is fixedly mounted on the fixed housing (9) The center of the electric cylinder (8) is equipped with a push-pull rod; the rocker slider mechanism is composed of a movable hinge seat (7), a connecting rod (6), a sliding hinge seat (5), and a connecting bolt (4). The two ends of desc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com