The connection structure and clothing of components and wires

A technology of connection structure and plug-in structure, applied in the field of smart wear, can solve the problems of reducing comfort, cumbersomeness, increase in volume and weight of wearable devices, etc., and achieve the effect of avoiding exposure and sealing the connection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

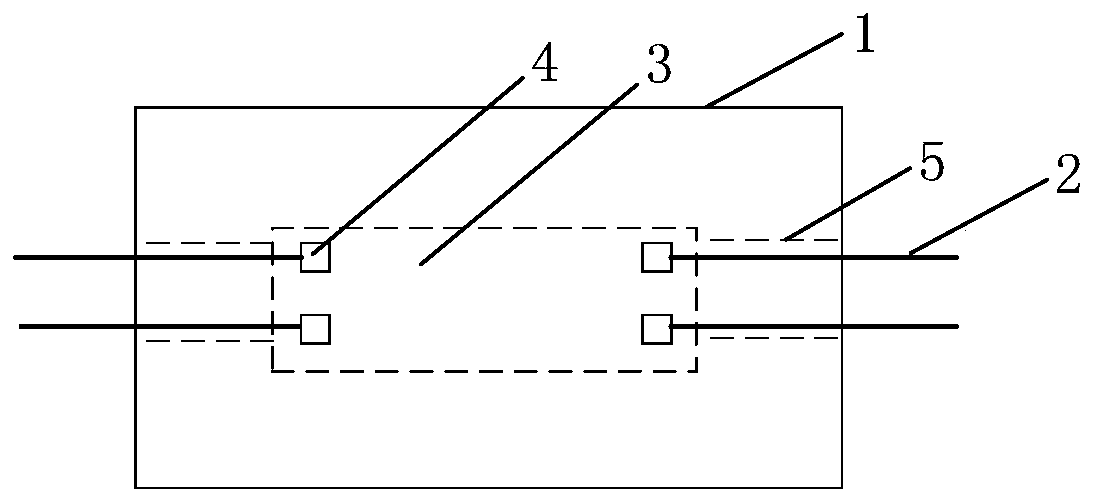

[0029] figure 1 Schematic diagram of the connection structure between components and wires provided by the embodiment of the present invention Figure 1 , the connection structure can be set on clothes as a wearable device. like figure 1 As shown, the connection structure between the component and the wire includes:

[0030] The component body 1 and the wire 2 form a cavity connection area 3 inside the component body 1, and at least one electrical signal terminal 4 is arranged in the cavity connection area 3, and the electrical signal terminal 4 is electrically connected to the internal circuit of the component body 1; A wire channel 5 is provided between the cavity connection area 3 and the outer wall of the element body 1 for the wire 2 to pass through; the wire 2 is connected to the electrical signal terminal 4, and the wire 2 leads to the outside of the element through the wire channel 5 .

[0031] Among them, the component body 1 is an independent component with certai...

Embodiment 2

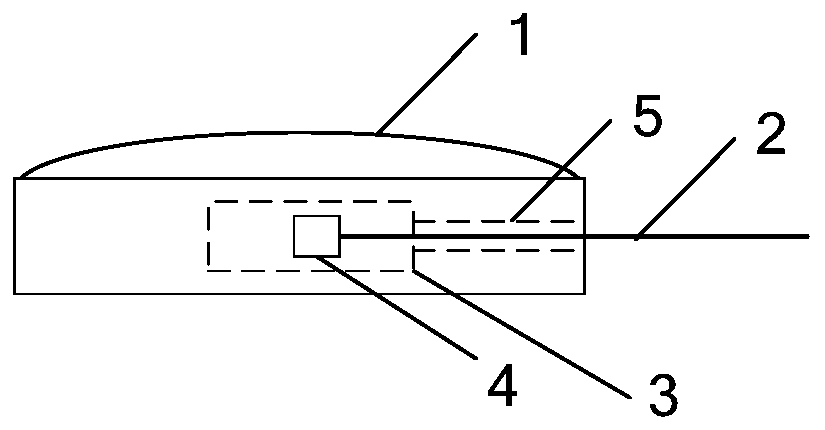

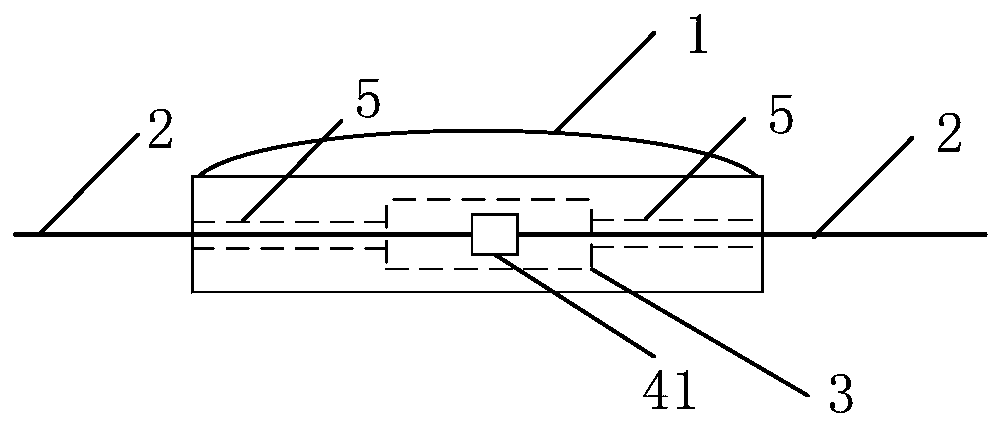

[0036] figure 2 and image 3 Schematic diagrams of other two connection structures between components and wires provided for the embodiments of the present invention, these two connection structures can be regarded as figure 1 The specific implementation of the shown structure embodiment. in contain figure 1 Based on all structural features shown, figure 2 and image 3 From the perspective of the layout of the wires in the wire channel, the connection structure of this embodiment will be described in detail.

[0037] Usually, when the interconnection relationship between components is relatively simple, and the electrical signal terminal drawn out of each component body 1 has only an interconnection relationship with one external component, it can be used figure 2 The connection structures shown enable the interconnection between elements. figure 2 The structure of can be regarded as one of the most basic connection structures.

[0038] figure 2Among them, each el...

Embodiment 3

[0049] Figure 4 The schematic diagram of the connection structure between the components and the wires provided by the embodiment of the present invention can be regarded as figure 1 The specific implementation of the shown structure embodiment. in contain figure 1 Based on all structural features shown, combined Figure 4 The connection structure of this embodiment is described in detail from the perspective of the specific connection manner between the components and the wires.

[0050] like Figure 4 In , the connection between the component and the wire can be fixed at one time by a similar welding method. This connection method does not need to be provided with an intermediate interface for plugging and unplugging wires to the electrical signal terminal 4, only the electrical pins of the electrical signal terminal 4 need to be exposed in the cavity connection area 3, and pre-installed in the cavity connection area 3 It is sufficient to leave the space occupied by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com