Rotary safety container cover

A safety container and rotating technology, which is applied in the direction of drinking water containers, can solve problems such as complex structure, positioning position deviation, and easy damage of buckle parts, so as to avoid excessive rotation angle and increase the safety of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further illustrated and explained below in conjunction with specific embodiments, and it should be understood that the following embodiments are only used to illustrate the present invention rather than limit the scope of the present invention.

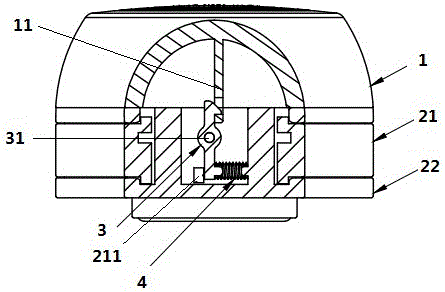

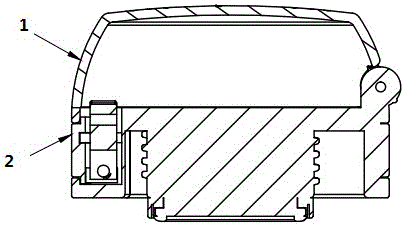

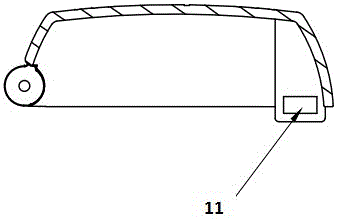

[0027] see Figure 1-Figure 3 , the invention provides a rotary safety container cover. As shown in the figure: it includes a flip cover 1 and a lower cover 2 connected to the flip cover 1 through a rotating shaft; the lower cover 2 is composed of a lower cover fixed ring 22 and a lower cover movable ring 21 sleeved outside the lower cover fixed ring 22; The lower cover fixing ring 22 is provided with a hook 3 that can rotate around the shaft 31. The hook portion of the hook 3 is located at the upper end. The lower end of the hook 3 is connected to one end of the return spring 4, and the other end of the return spring 4 is connected to the lower cover. On the fixed ring 22; the lower end of the ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com