Muddy water extraction device

A technology for extracting equipment and muddy water, which is applied in the direction of wellbore/well components, earthwork drilling and mining, etc. It can solve the problems of damage to the camera device, blocking the line of sight of the camera device, etc., and achieve the effect of rapid extraction, small impact, and prevention of water leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

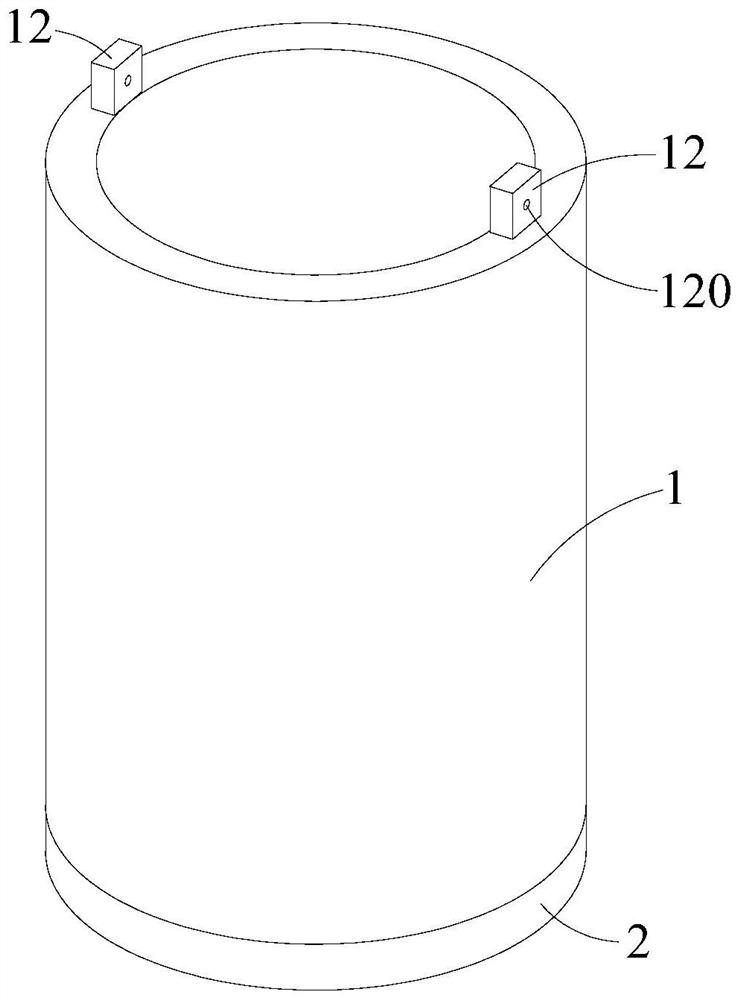

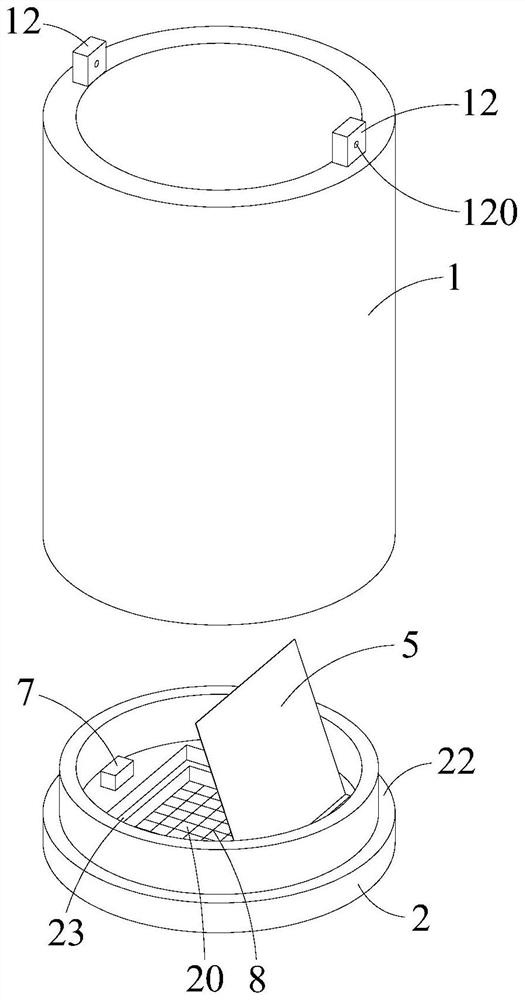

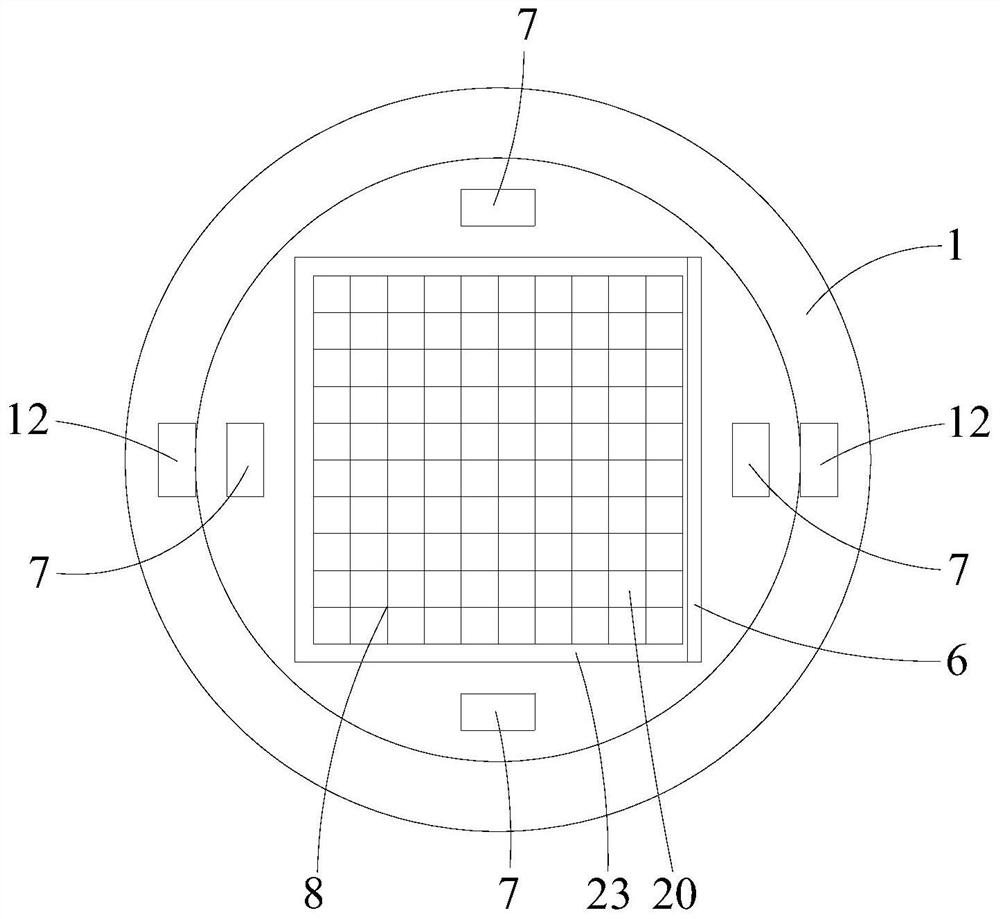

[0045] see Figure 2 to Figure 4, the muddy water extraction device provided in Embodiment 1 of the present application will now be described. The muddy water extracting device includes a casing 1 with an accommodating chamber and a base 2 connected to one end of the casing 1 ; the base 2 is provided with an opening 20 communicating with the accommodating chamber of the casing 1 . The muddy water extraction device also includes a cover plate 5 for covering the opening 20 and a stopper 6 for limiting the rotation angle of the cover plate 5; On the side of the chamber, the limit stopper 6 is installed on the base 2. Among them, the casing 1 and the base 2 are detachably connected, such as through bolt connection, buckle connection, etc., which facilitate the quick disassembly and assembly of the base 2, and the replacement of the drill bit to realize the drilling operation and realize the multi-purpose of the mud water extraction device . With this structure, the present appl...

Embodiment 2

[0053] see Figure 7 , Figure 9 and Figure 10 Now, the muddy water extracting device provided in the second embodiment of the present application will be described. The difference between the muddy water extraction device provided in the second embodiment of the present application and the muddy water extraction device provided in the first embodiment is that the muddy water extraction device also includes a connecting pipe 3 sleeved on the casing 1, and the inner side wall of the connecting pipe 3 faces the casing. The direction of the pipe 1 is protrudingly provided with a first retaining ring 31 and a second retaining ring 32, and the first retaining ring 31 and the second retaining ring 32 are arranged at intervals; 31 or the second stop ring 32 cooperates with the third stop ring 13 to limit the movement stroke of the connecting pipe 3 , and the third stop ring 13 is arranged between the first stop ring 31 and the second stop ring 32 . With this structure, by sheathi...

Embodiment 3

[0058] see Figure 12 to Figure 14 Now, the muddy water extracting device provided in the third embodiment of the present application will be described. The difference between the muddy water extraction device provided in the third embodiment of the present application and the muddy water extraction device provided in the first embodiment is that the muddy water extraction device also includes an extension pipe 4 sleeved on the casing 1, and the outer wall of the casing 1 is along the The axial direction of the sleeve 1 is provided with a first guide groove 15, and the inner side wall of the extension pipe 4 is correspondingly installed with a guide block 41 extending into the first guide groove 15; A second guide groove 16 for sliding the guide block 41 is also provided in the circumferential direction, and the first guide groove 15 communicates with the second guide groove 16 . With this structure, the extension pipe 4 can move up and down along the casing 1 along the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com