Clamp of overflow plate

An over-current and fixture technology, applied in the direction of clamping, manufacturing tools, supports, etc., can solve the problems of low efficiency, cumbersome clamping, complex structure, etc., and achieve the effect of easy operation, reducing positioning interference, and improving clamping efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

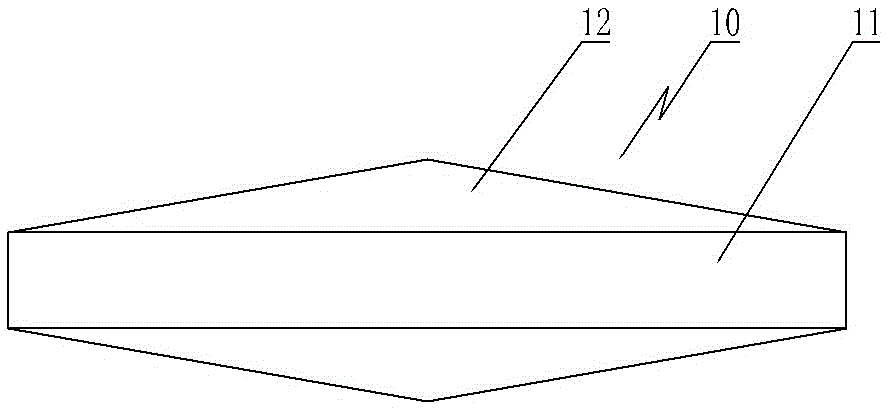

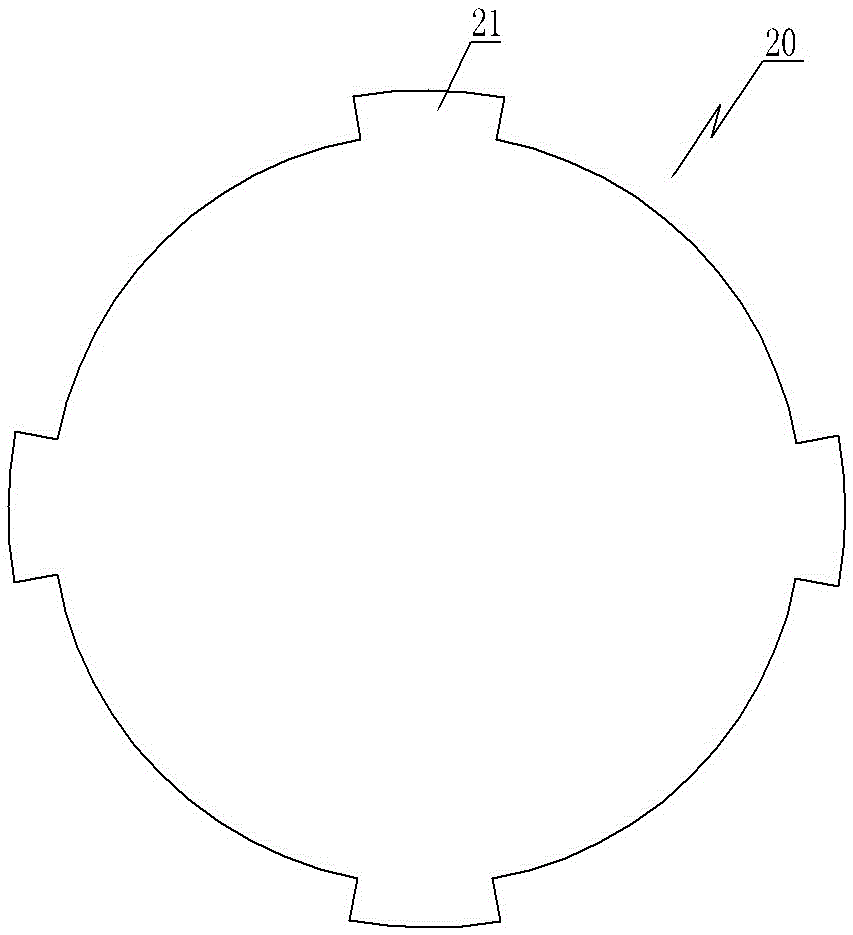

[0022] Such as Figure 1 to Figure 7 As shown, the clamp 30 of the overflow plate includes a movable clamp block 31, a fixed clamp block 32, and a pressing mechanism for pressing the movable clamp block 31 to be fixed on the fixed clamp block 32; the movable clamp block 31 is provided with The first positioning groove, the first positioning groove includes the first upper groove body 311, the first middle groove body 312 and the first lower groove body 313 connected to each other; the fixed clip 32 is provided with the second positioning groove, the second positioning groove It includes a second upper tank body 321, a second middle tank body 322 and a second lower tank body 323 connected to each other; the first upper tank body 311 is a V-shaped groove, and the inner side walls of the tank body 3111, 3112 of the first upper tank body 311 , 3113 are respectively tangent to the side of the columnar main body of the semi-finished product, the second middle tank body 322 is an arc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com