Work fixture for transition plate

A tooling fixture and overcurrent technology, applied in the direction of manufacturing tools, clamping, positioning devices, etc., can solve the problems of cumbersome clamping, complex structure, low efficiency, etc., to reduce positioning interference, improve clamping efficiency, and easy to operate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

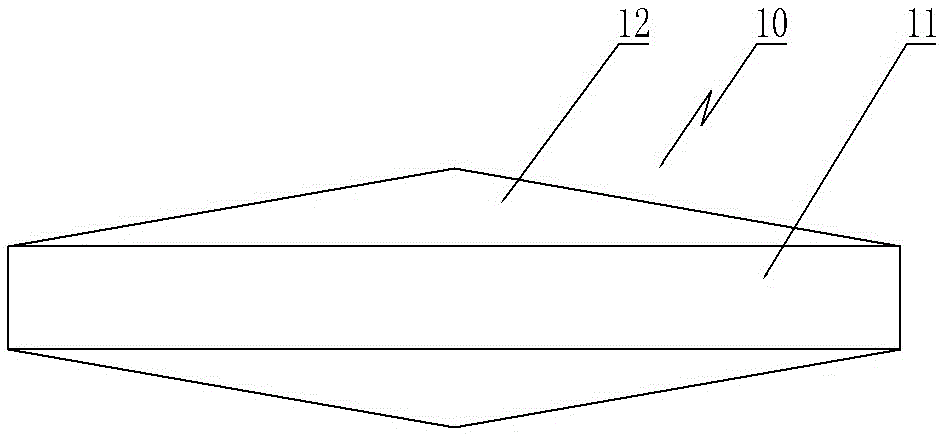

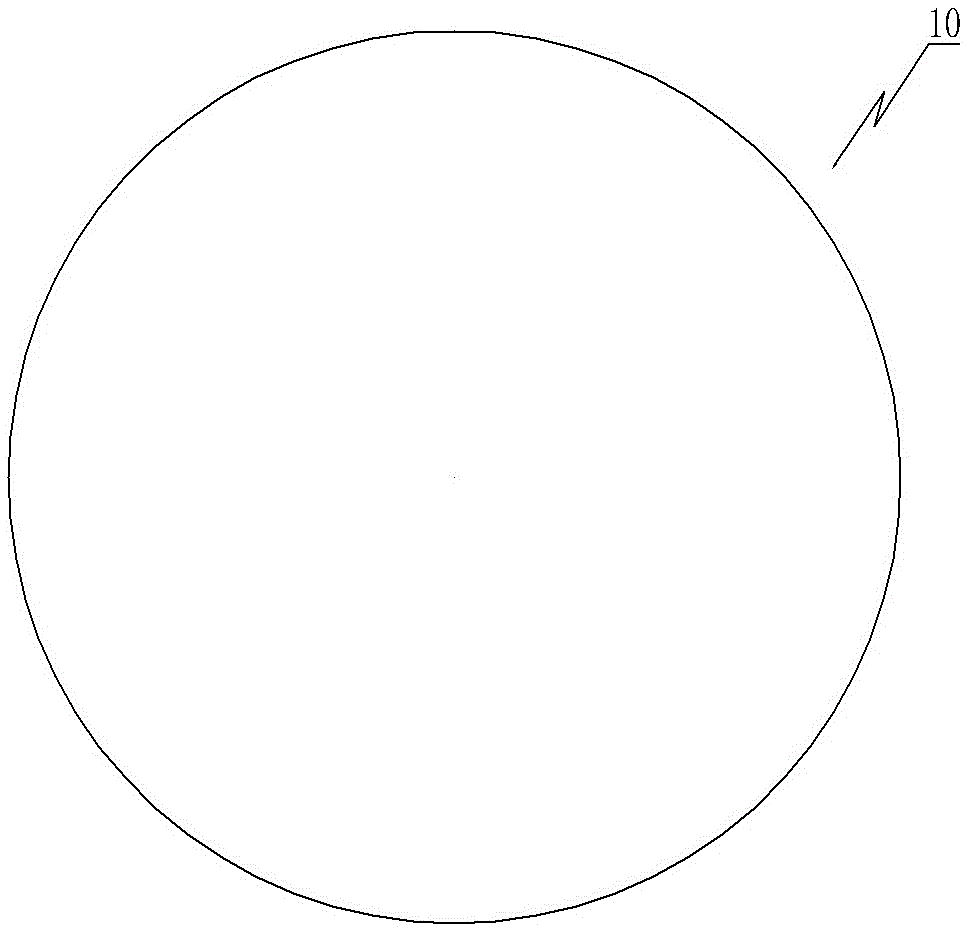

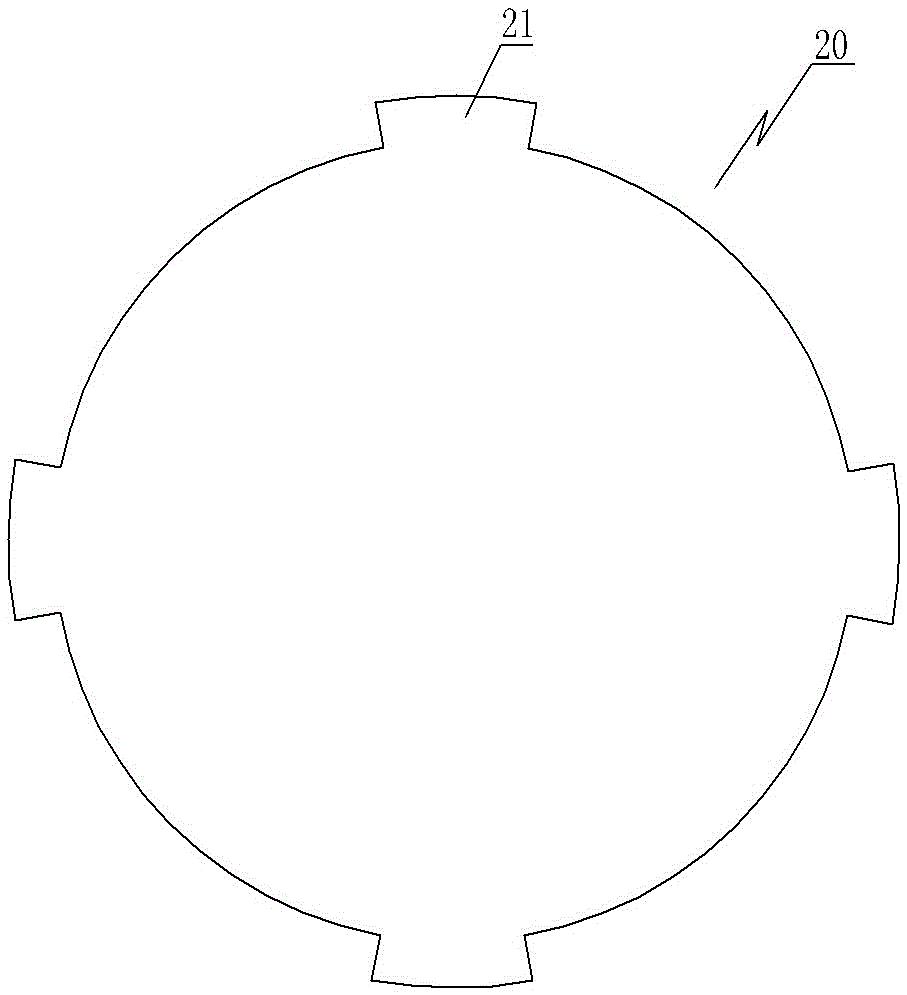

[0021] Such as Figure 1 to Figure 6 As shown, the fixture 30 of the flow plate includes a movable clamp block 31, a fixed clamp block 32, and a pressing mechanism for press-fitting and fixing the movable clamp block 31 on the fixed clamp block 32; the movable clamp block 31 is provided with There is a first positioning groove. The first positioning groove includes a first upper groove body 311, a first middle groove body 312 and a first lower groove body 313 that are connected to each other; a second positioning groove is provided on the fixing clamp block 32, and the second positioning groove The groove includes a second upper groove body 321, a second middle groove body 322 and a second lower groove body 323 which are connected to each other; the first upper groove body 311 and the second middle groove body 322 are combined to form a semi-finished cylindrical body with the flow plate Matching cylindrical positioning grooves, the first middle groove body 312 and the second mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com