Production device realizing continuous ink-jet 3D printing and working method

A 3D printing and production device technology, applied in the field of 3D printing, can solve the problems of unsuitable batch production and low printing efficiency, and achieve the effect of improving flexibility and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

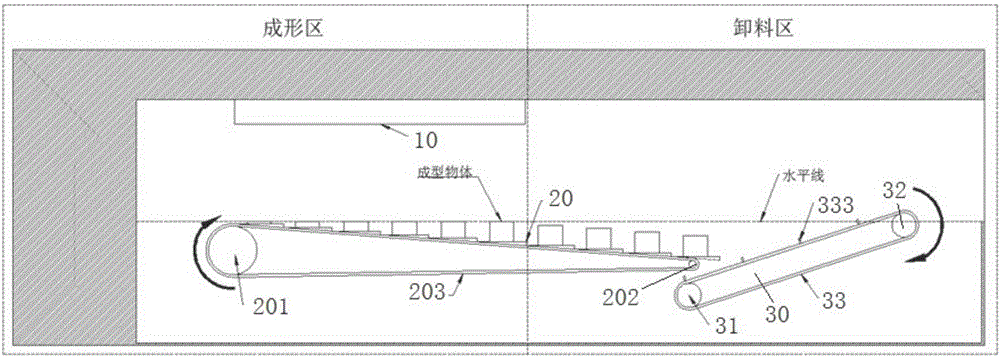

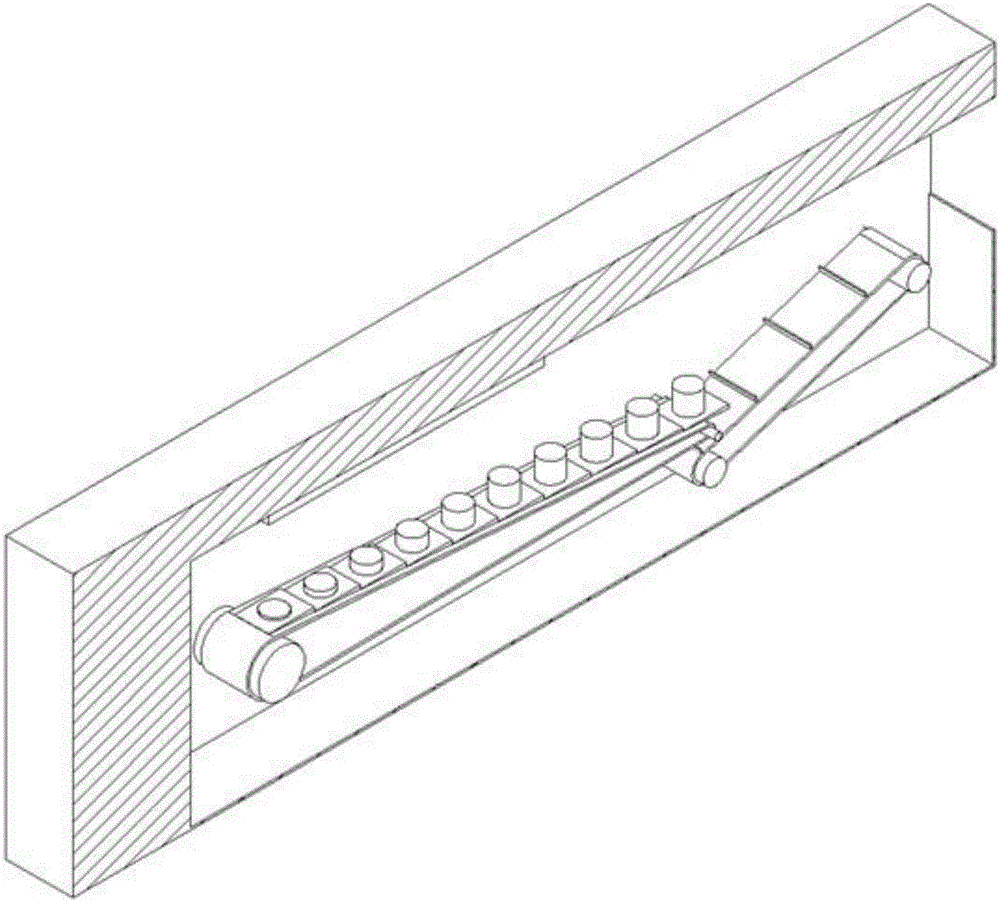

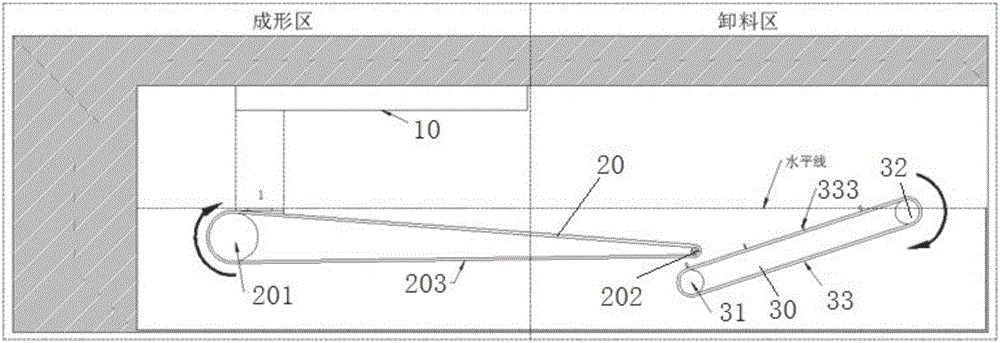

[0045] Embodiment 1: The starting end of the transmission is horizontally transitioned to the end of the transmission through the conveyor belt. The distance between the nozzles in the nozzle set and the vertical direction of the first conveying device gradually increases from the starting end of the transmission to the end of the transmission. Such a design can To overcome the fact that the nozzles are far away from the printing plane, the sprayed liquid particles will float, and ensure that each nozzle is at the same vertical distance from the upper surface of the cured product on the corresponding area to be printed at the same time, so as to improve the accuracy of the printing process as much as possible Further, the distance in the vertical direction between the nozzles in the nozzle set above the delivery starting end and the nozzles in the nozzle collection above the delivery end is not less than the height of the printed cured product .

[0046] as attached figure 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com