A dual-group synchronous separation device for a spacecraft hydraulic circuit breaker

A separation device and disconnector technology, applied in the field of spacecraft, can solve the problems that can only be installed outside the bulkhead, occupy the carrying envelope space, unfavorable disconnector matching pipeline and cable routing layout, etc., to achieve improved Reliability and safety, improved reliability, and ease of repeated disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

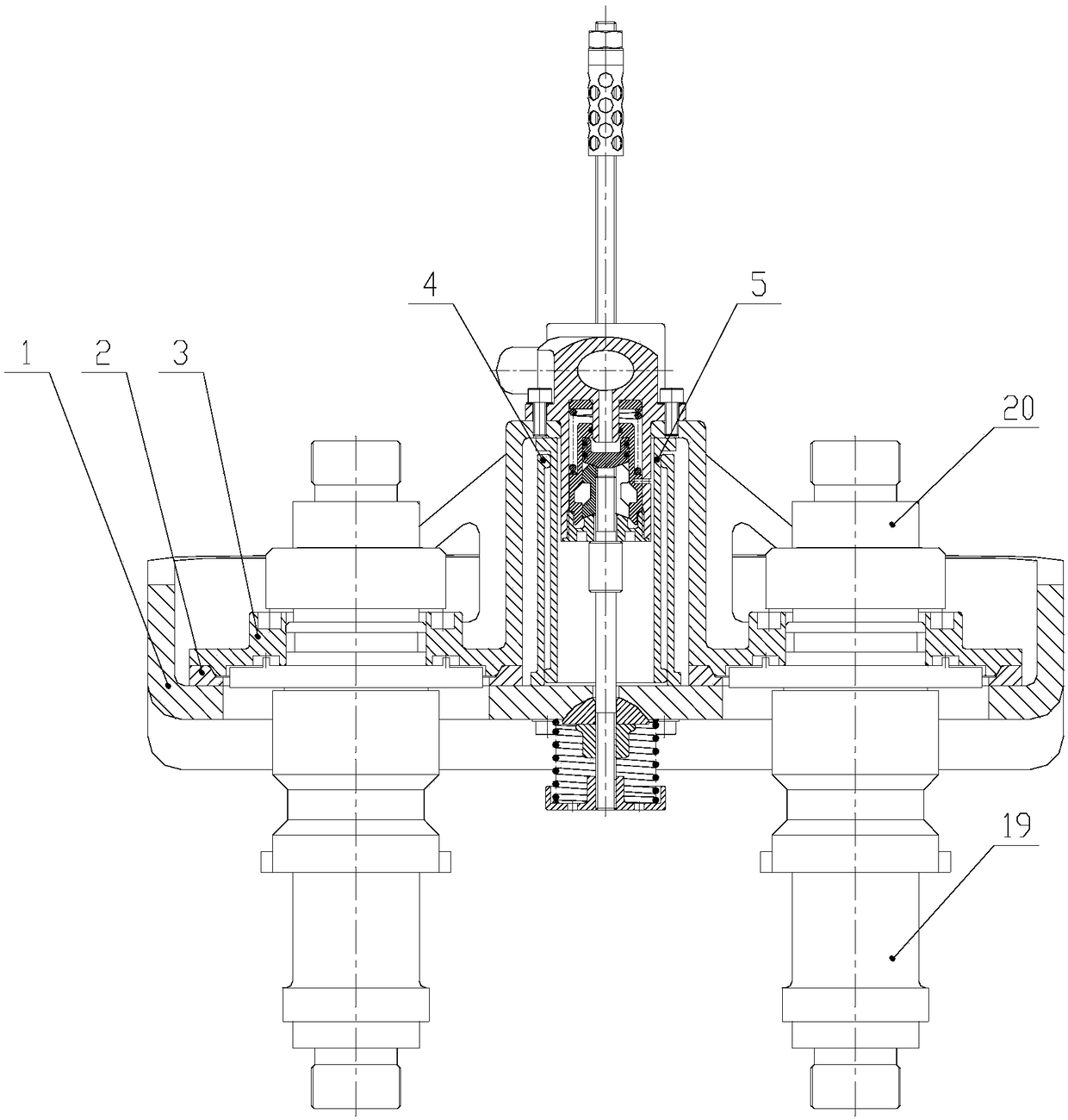

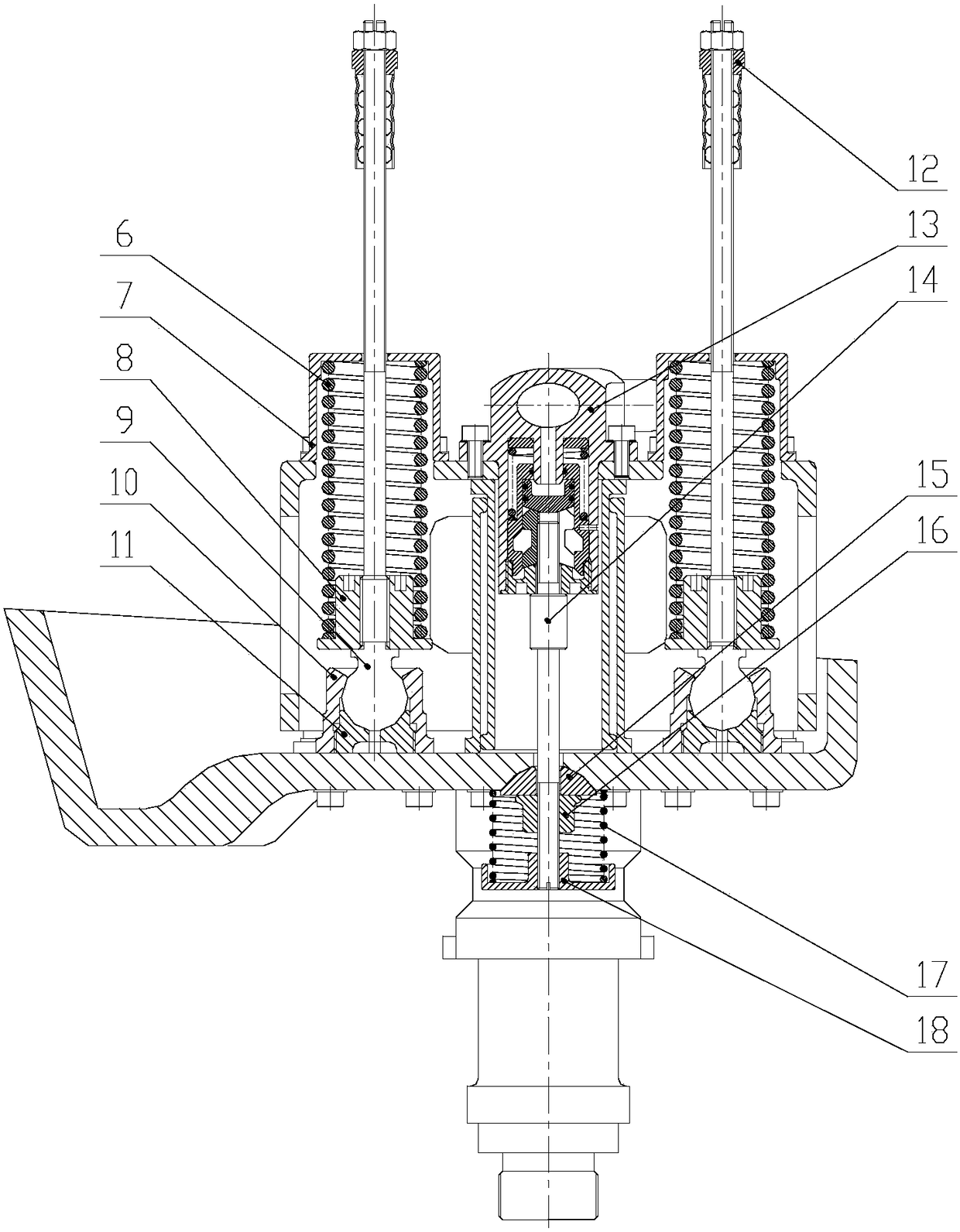

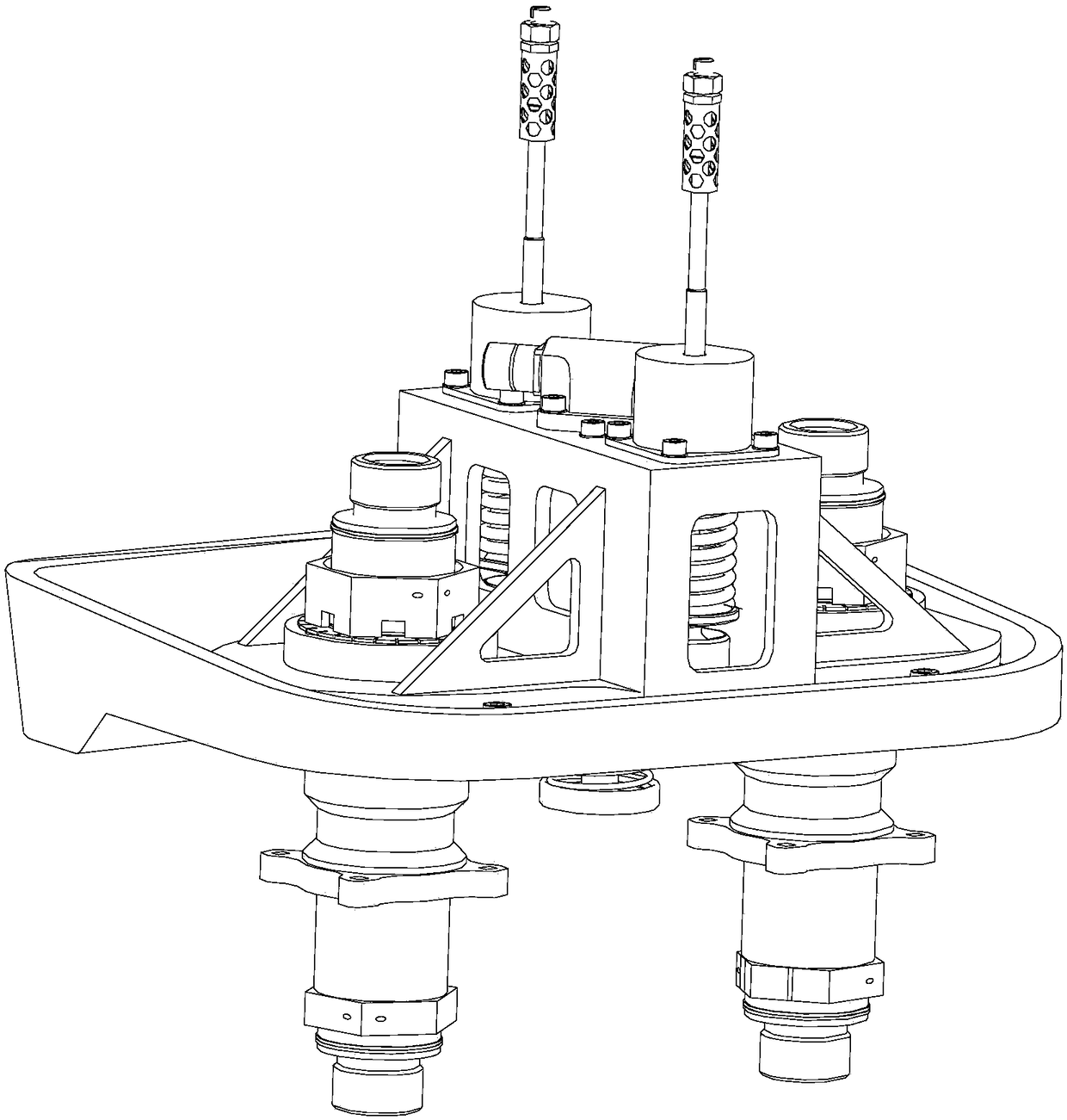

[0040] The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0041] The invention provides a dual-group synchronous separation device for a spacecraft liquid circuit breaker, see the attached figure 1 with 2 , including: two sets of separation power components, fixed base 1, positioning cone seat 2, separation bracket 3, guide outer cylinder 4, guide inner cylinder 5, separation nut 13, connecting screw 14, locking ball pad 15, lock nut 16. The rod spring 17 and the spring cap 18;

[0042] The locking ball pad 15 is a spherical structure;

[0043] The fixing base 1 is processed with installation holes for installing two liquid circuit breakers, and its center is processed with a ball slot for installing the locking ball pad 15;

[0044]The positioning cone seat 2 is processed with mounting holes for installing two liquid circuit breakers, the inner peripheral surface of the mounting hole of the positioning cone s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com