Electrostrictive composite material, and preparation method and applications thereof

A composite material and stretchable technology, applied in medical science, prosthesis, tissue regeneration, etc., can solve the problems of performance gap, high driving voltage, small output stress, etc., and achieve good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

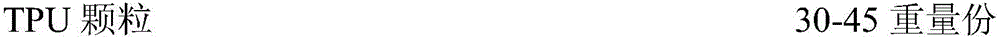

[0028] In this embodiment, the electrostrictive composite material is mainly prepared from the following raw materials in parts by weight:

[0029]

[0030] The preparation method comprises the following steps:

[0031] Dry each raw material at 50°C for 2 hours in advance, mix evenly, and extrude through a casting machine. The temperature of each section of the casting machine is set as follows: the temperature of the barrel is 140°C; the temperature of the filter is 150°C; the temperature of the elbow is 160° C.; the connection temperature is 135° C.; the die head temperature is 150° C. to obtain the electrostrictive composite material.

Embodiment 2

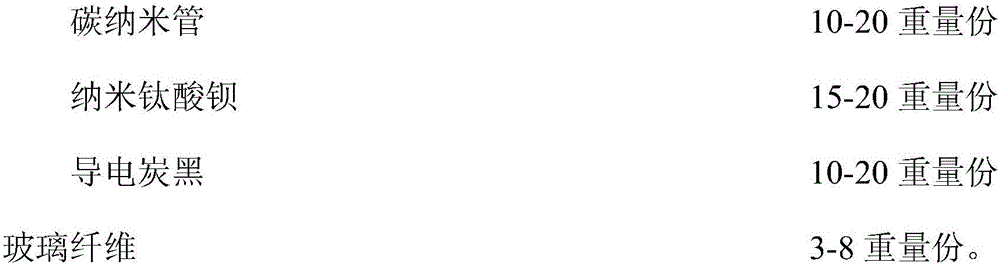

[0033] In this embodiment, the electrostrictive composite material is mainly prepared from the following raw materials in parts by weight:

[0034]

[0035] The preparation method comprises the following steps:

[0036] Dry each raw material at 60°C for 1.5 hours in advance, mix evenly, and extrude through a casting machine. The temperature of each section of the casting machine is set as follows: the temperature of the barrel is 140°C; is 150°C; the connection temperature is 150°C; the die head temperature is 165°C, and the electrostrictive composite material is obtained.

Embodiment 3

[0038] In this embodiment, the electrostrictive composite material is mainly prepared from the following raw materials in parts by weight:

[0039]

[0040] The preparation method comprises the following steps:

[0041] Dry each raw material at 55°C for 1 hour in advance, mix evenly, and extrude through a casting machine. The temperature of each section of the casting machine is set as follows: the barrel temperature is 135°C; the filter screen temperature is 145°C; the elbow temperature is 160° C.; the connection temperature is 135° C.; the die head temperature is 150° C. to obtain the electrostrictive composite material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com