A high-precision rigid height and angle adjustment device

An angle adjustment device, high-precision technology, applied in the direction of building types, buildings, building components, etc., can solve problems such as insufficient horizontal and vertical stiffness, device deformation, and impact on the performance of shock-isolation bearings to achieve high stiffness and avoid interference , the effect of large height adjustment range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

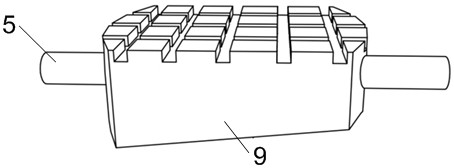

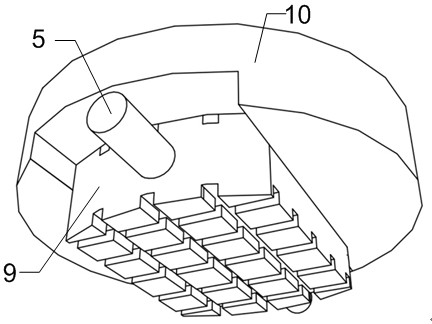

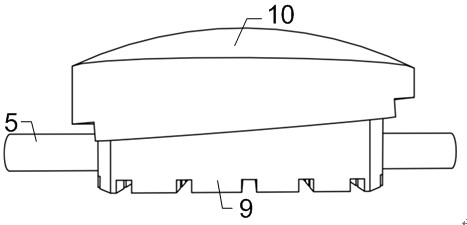

[0030] Example 1: The high-precision rigid height and angle adjustment device as shown in the figure, including the lower seat plate 1, the lower slider 9, the upper slider 10, the upper seat plate 2, the adjustable length bolts 3, the threaded holes 8, the upper seat plate Threaded countersunk hole 11, upper seat plate limit bolt 4, upper slider limit bolt 6, lower slider limit bolt 7 and long screw 5. The lower seat plate 1 is composed of two parts: a square steel plate and a thick-walled steel pipe. The square steel plate of the lower seat plate 1 is provided with four threaded holes 8 for connecting the rigid ground. From bottom to top, the thick-walled steel pipes of the lower seat plate 1 are respectively connected with the lower slider 9 , the upper slider 10 , and the upper seat plate 2 . The bottom surface of the lower slider 9 is flat, the top surface is an inclined surface, and oil grooves are opened on the bottom surface and the top surface to prevent foreign obje...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com