Fastening clips for building concrete reinforcement

A technology of concrete reinforcing bars and fixing cards, which is applied to buildings, building components, building reinforcements, etc., can solve the problems of limitation of lateral steel bars, high labor intensity, large volume, etc., so as to improve construction progress and quality, easy to use, Symmetrical effect of the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

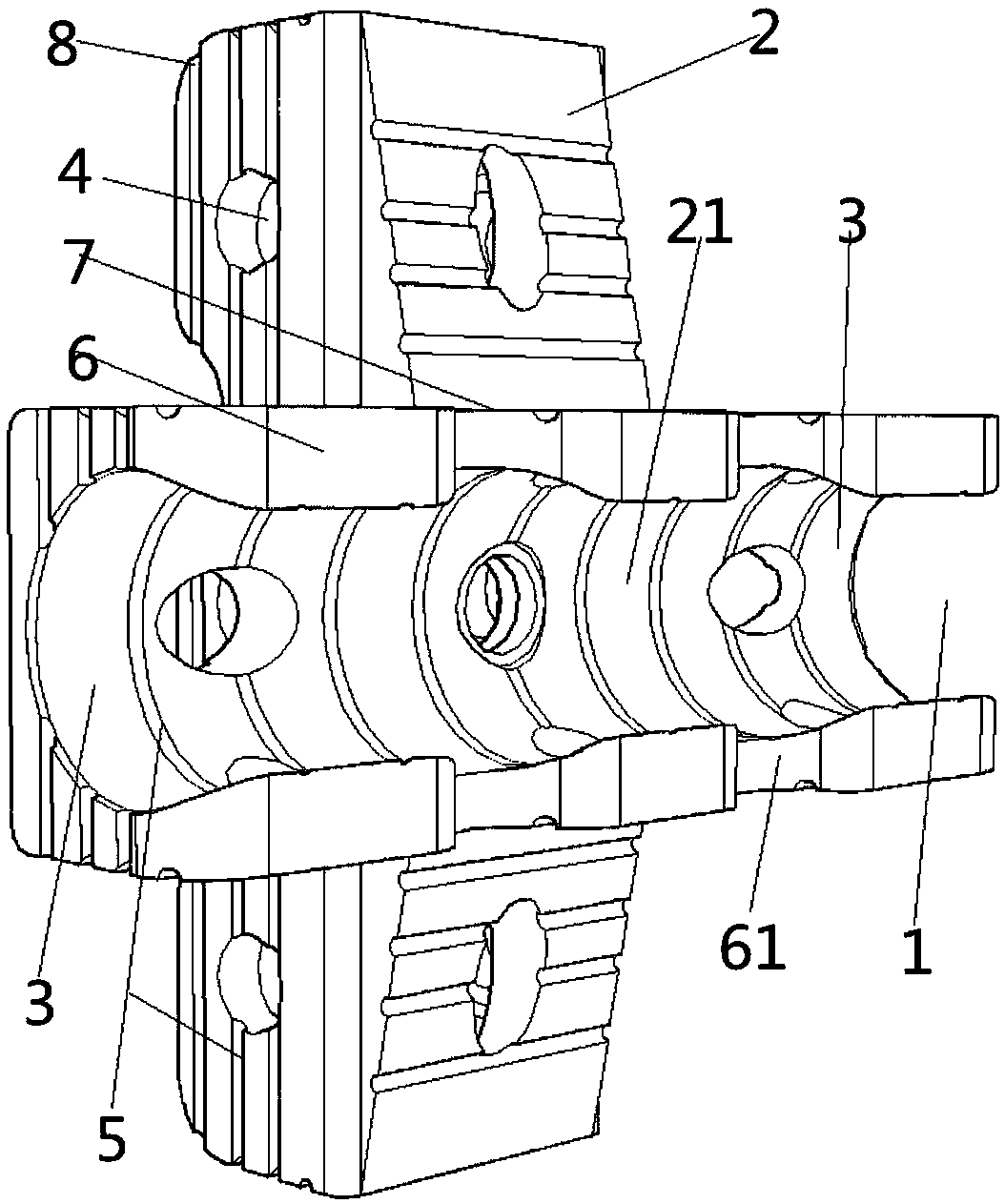

[0021] Such as figure 1 As shown, the fixing card used for building concrete reinforcement is composed of two connected C-shaped straight-through groove main bodies 21 on different planes that are vertically intersected. When in use, the reinforcement is pressed into the C-shaped groove 3 along the opening 1 for positioning. And fixed, instead of manually binding steel bars with thin steel wires.

[0022] The main bodies 21 of the C-shaped straight through grooves are straight through grooves, and the non-opening sides of the two C-shaped straight through groove bodies 21 intersect perpendicularly with each other, and the openings 1 of the two C-shaped straight through groove main bodies 21 are all facing outward. A C-shaped slot 3 is provided in each C-shaped through-slot main body 21 , and a through hole 4 is provided on the C-shaped through-slot main body 21 . Wherein, the through hole 4 is circular or elliptical, so that the concrete slurry can contact the steel bar throu...

Embodiment 2

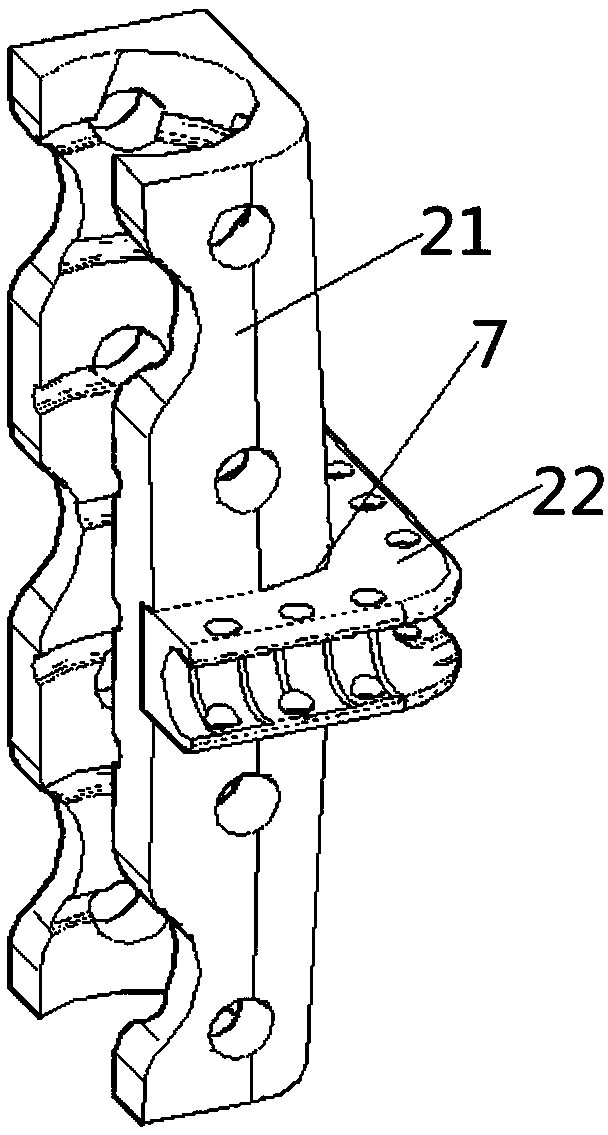

[0027] Such as figure 2 As shown, the fixing card used for building concrete reinforcement is composed of a C-shaped straight-through groove main body 21 and a C-shaped right-angle groove main body 22, and the non-open side of the C-shaped right-angle groove main body 22 is fixed on the C-shaped straight groove The non-open side of the main body 21 . The non-opening sides of the C-shaped straight-through groove main body 21 and the C-shaped right-angle groove main body 22 perpendicularly intersect each other, and the vertical intersection 7 is a right-angled surface.

[0028] Wherein, the apertures of the respective C-shaped grooves 3 of the C-type straight-through groove main body 21 and the C-shaped right-angle groove main body 22 are different; the aperture of the C-shaped groove 3 is designed according to the diameter of the steel bar being pressed in, and the steel bar that is pressed in is required to be the same as the C-shaped groove. Groove 3 is a tight fit. The po...

Embodiment 3

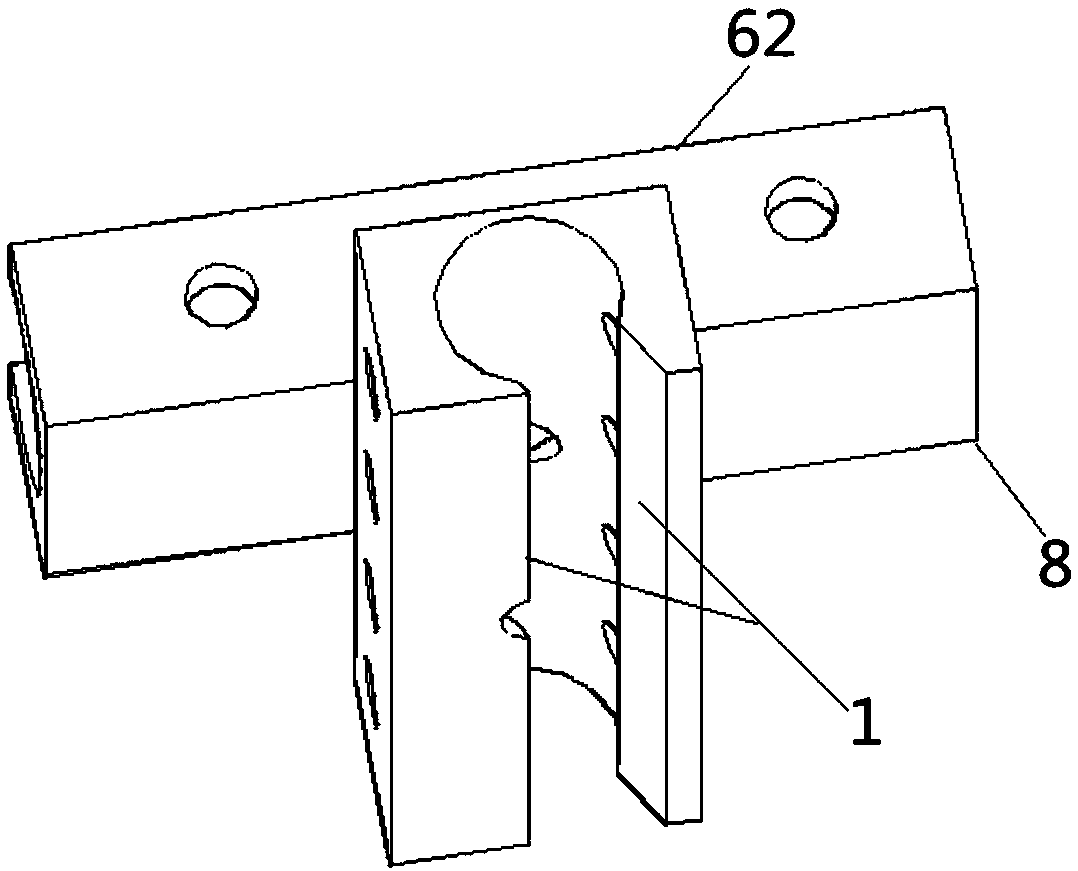

[0031] Such as image 3 As shown, the fixing card used for building concrete reinforcement is composed of two connected C-shaped straight-through groove main bodies 21 on different planes that are vertically intersected. When in use, the reinforcement is pressed into the C-shaped groove 3 along the opening 1 for positioning. And fixed, instead of manually binding steel bars with thin steel wires. The structure of embodiment 3 is similar to that of embodiment 1, except that the two sides 6 of the main body 21 of the C-shaped straight through groove are right-angled sides 62 . The end portion 8 of the C-shaped straight through groove main body 21 is a right angle. The opening 1 of the main body 21 of the C-shaped straight through groove is an asymmetrical opening, as long as the steel bars can be fixed smoothly.

[0032] The fixing clip for building concrete reinforcement is made of metal materials, high molecular polymer materials, recycled high molecular polymer materials or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com