Construction method of polycarbonate uniform constitutive model based on tensile tests and compression tests

A polycarbonate, constitutive model technology, applied in measurement devices, instruments, scientific instruments, etc., can solve problems such as poor accuracy of the constitutive model

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

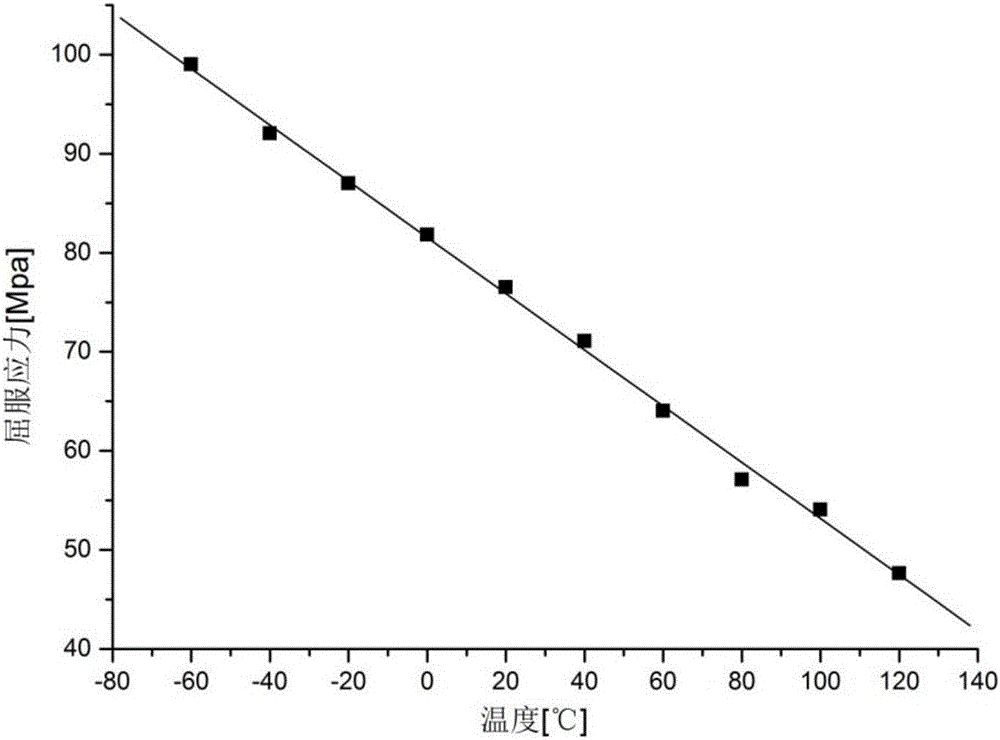

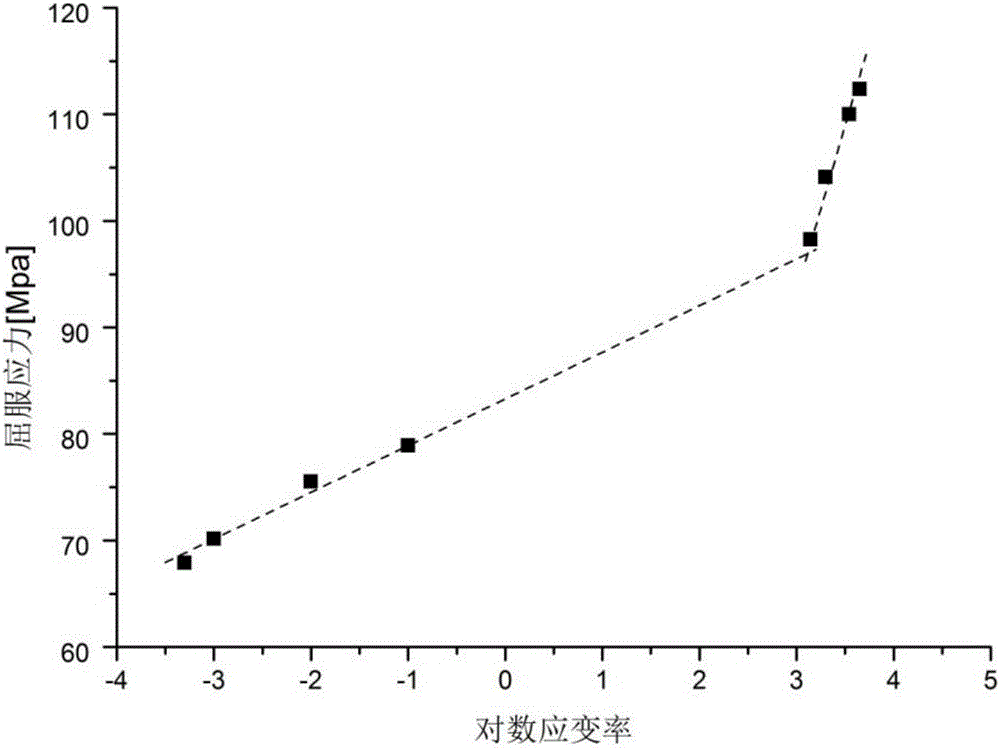

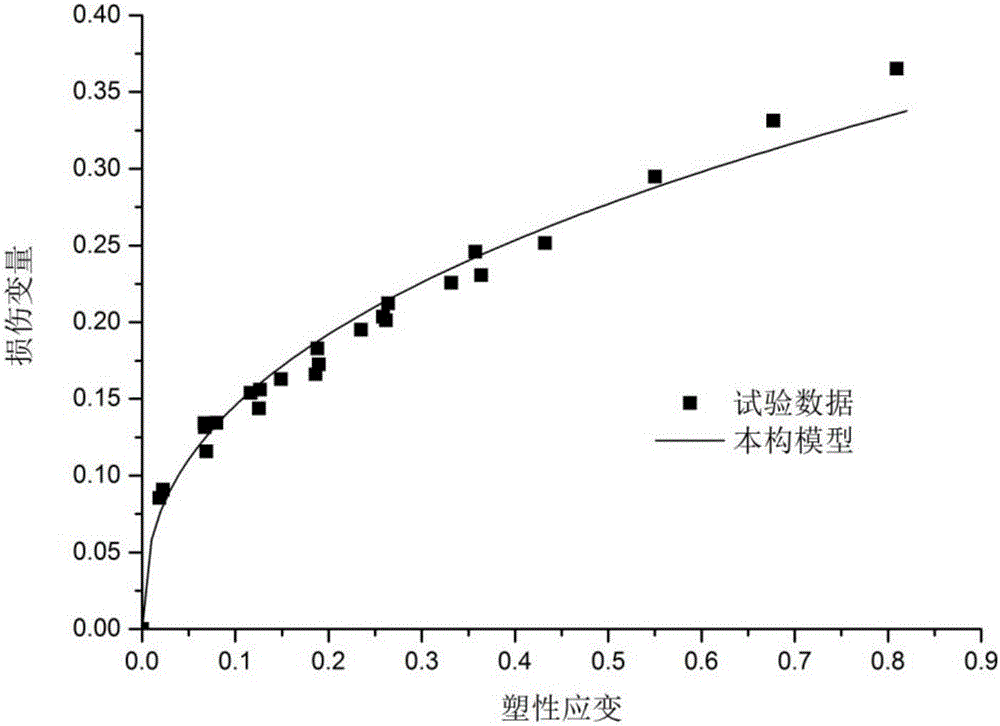

[0029] refer to Figure 1-5 . The concrete steps of the construction method of the polycarbonate unified constitutive model based on tensile and compression experiments of the present invention are as follows:

[0030] The tensile and compressive parameters in the unified constitutive model are not the same, but because the test method and parameter determination method are consistent, the following is only for polycarbonate at different temperatures (-60-120°C) and different strain rates (0.0005s -1 , 0.001s -1 , 0.01s -1 , 0.1s -1 , 1400s -1 , 2000s -1 , 3500s -1 , 4500s -1 ) from the test data obtained from the tensile test, and the relevant parameters were fitted, and the calculated results were compared and verified with the real test results.

[0031] Step 1: Through the quasi-static uniaxial tensile test, the current conditions (25°C, 0.01s -1 ) under the true stress-strain curve of polycarbonate, calculate its elastic modulus according to the data of its linea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com