A filter apparatus for filtering a stream of gas

A filter and gas flow technology, which is applied in membrane filters, dispersed particle filtration, chemical instruments and methods, etc., can solve the problems of inconvenient removal of filter cartridges, filter design limitations, and difficulty in handling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

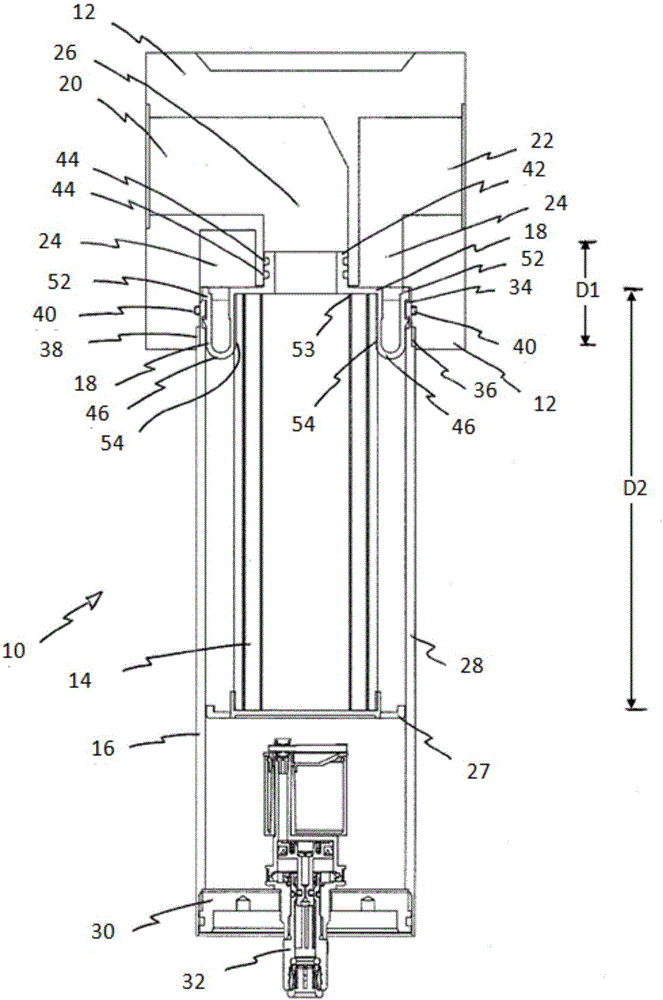

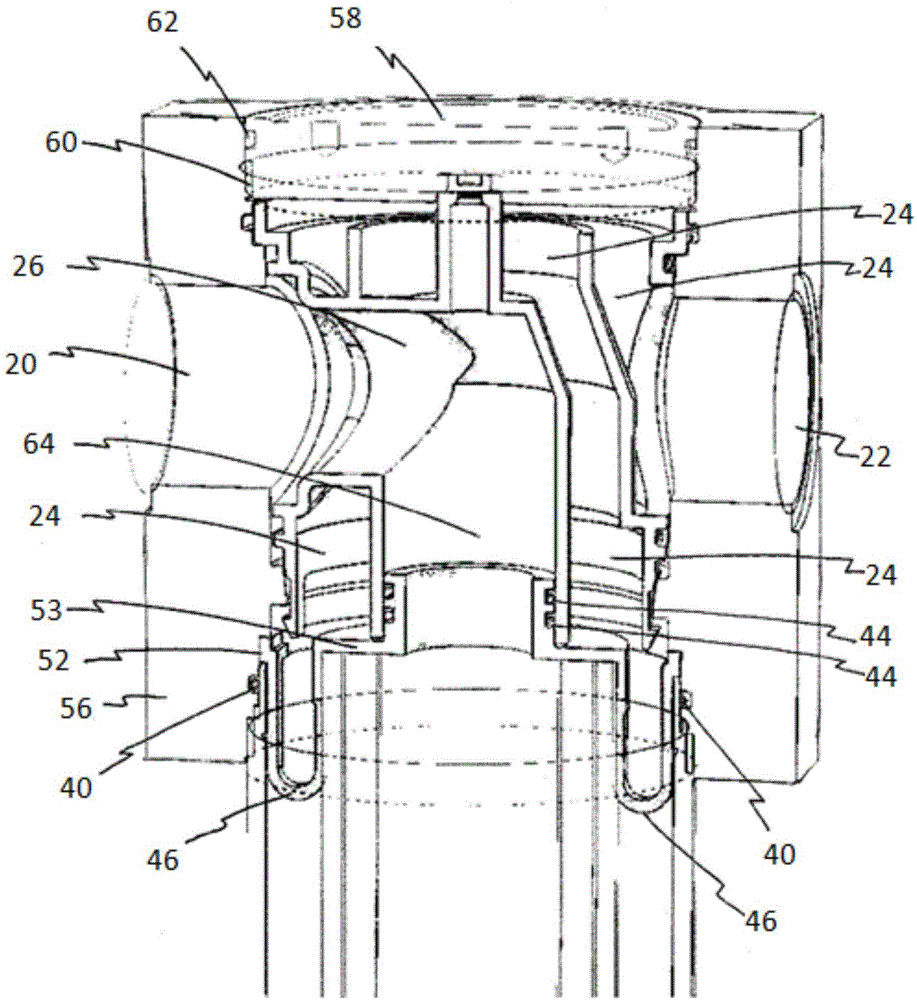

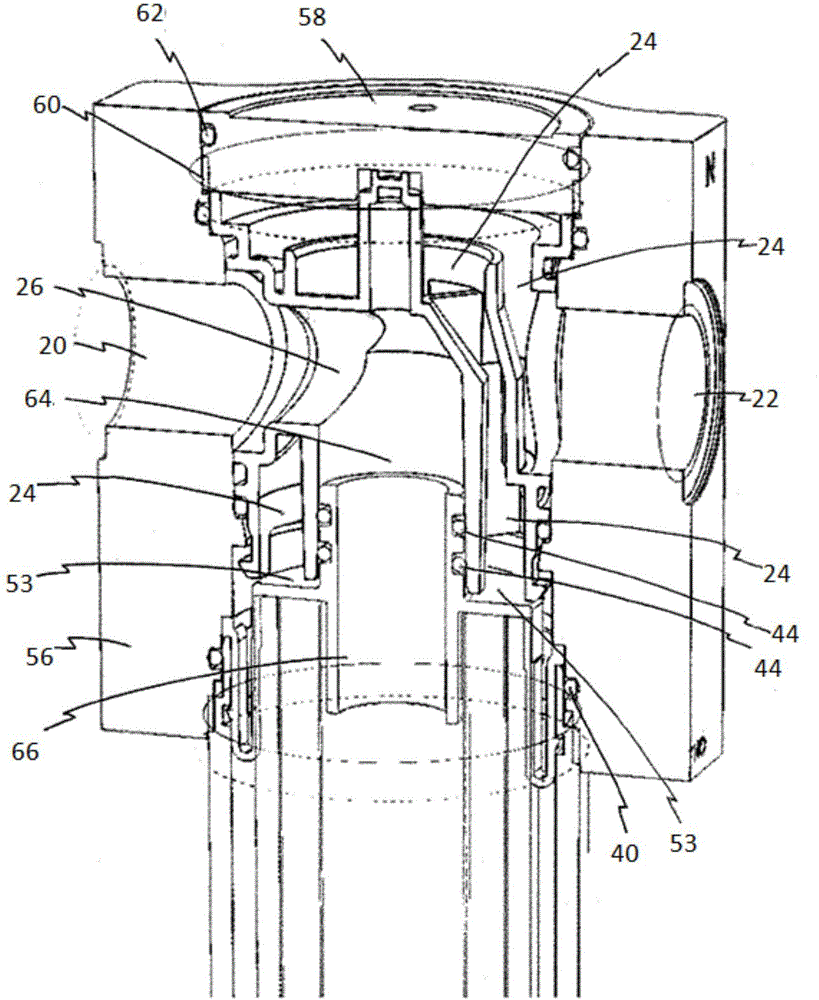

[0031] refer to figure 1 , shows a filter device 10, and this device is used to filter a gas flow. In particular, apparatus 10 is used to filter compressed air streams, which is typically performed prior to the drying step in compressed air purification processes. The four main components of the filter apparatus are the head end 12, the filter 14, the cartridge 16 and the connector 18 connecting the head end, filter and cartridge together.

[0032] The filter head 12 has an inlet 20 for receiving a flow of compressed air. The head end 12 also has an outlet 22 through which compressed air passes to downstream equipment (not shown). Compressed air flows to and from the filter via a first conduit 24 and a second conduit 26 . The first conduit 24 substantially surrounds the second conduit 26, which enters the cartridge 16 and carries the filtered air flow to the outlet. A second conduit 26 is radially inward from the first conduit 24 and directs the flow of compressed air into...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap