Linear actuator

A technology of linear actuators and motors, applied in the direction of transmissions, electric components, electromechanical devices, etc., can solve problems such as expensive and complicated prices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

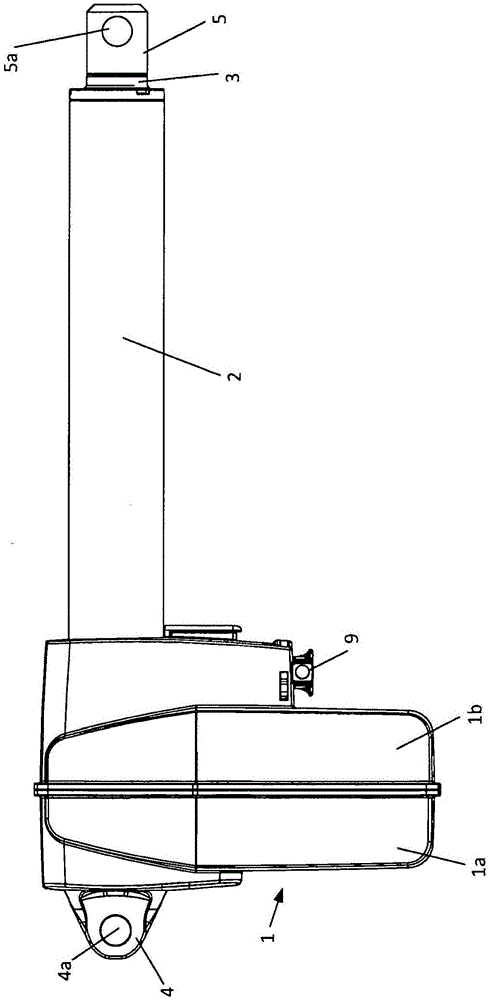

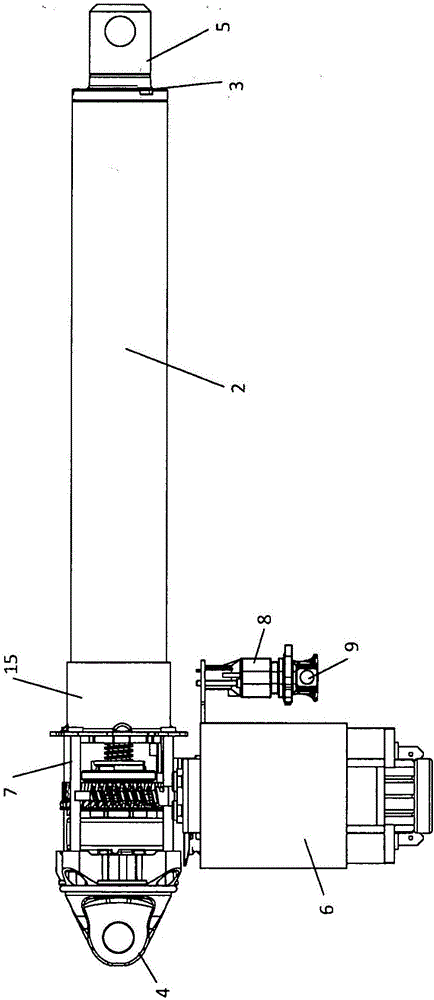

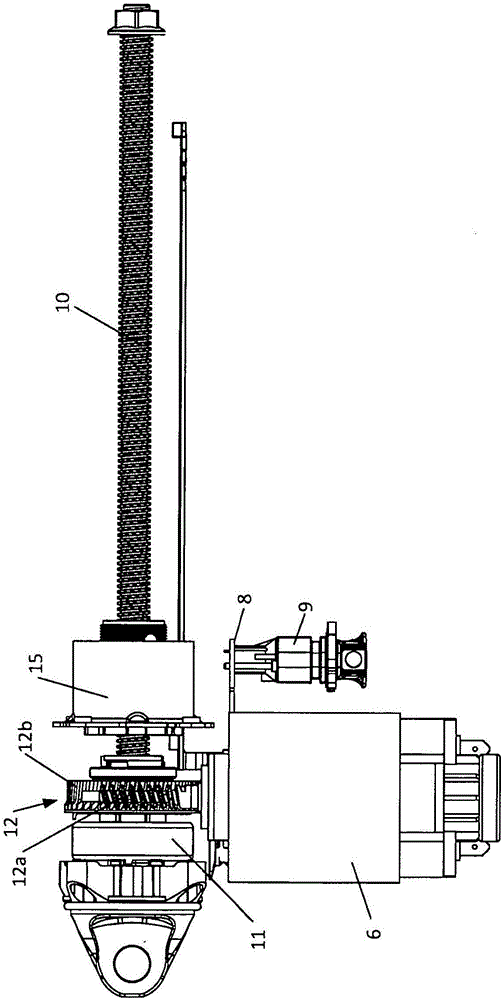

[0024] The linear actuator shown in the figures comprises a housing 1 consisting of a first part 1a and a second part 1b. Furthermore, the linear actuator comprises a catheter 2 and a tubular adjustment element 3 guided in said catheter 2 . For mounting the linear actuator, the rear end of the housing 1 is equipped with a rear mounting 4 and in the front end of the tubular adjustment element 3 a front mounting 5 is provided. Both the rear mounting part 4 and the front mounting part 5 have eyelets, through-holes 4a, 5a for bolts, rivets, pivot pins etc., by means of which the linear actuator can be fixed. The linear actuator is thus able to rotate around the central axis through the holes in the rear mount 4 and the front mount 5, so that the linear actuator automatically adapts the position of the two elements in the structure used to fix the linear actuator so that The force is always ideally transmitted axially along the longitudinal direction of the tubular adjustment elem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com