Online copper bar cutting machine

A technology of cutting machine and copper bar, applied in shearing device, shearing machine equipment, metal processing equipment and other directions, can solve the problems of increasing cutting cost, difficulty in recycling, danger, etc., to reduce production and processing cost, cut accurately, and avoid threats Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

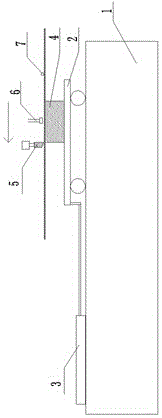

[0012] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0013] Such as figure 1 As shown, the wire cutting machine for copper bars includes a base 1, a trolley 2 arranged on the base 1, a knife seat 4 fixedly arranged on the trolley 2, an upper knife 5 for cutting copper bars, a downward pressure cylinder 6 and Meter counter 7, the trolley 2 is driven by the traction cylinder 3 to move the knife seat 4 horizontally to reset; the upper knife 5 is driven by a hydraulic cylinder, and the upper knife 5 and the vertical plane of the knife seat 4 do not overlap; The air cylinder 6 is set facing the center position of the knife seat 4; the press-down cylinder 6 cooperates with the knife seat 4 to fix the copper bar; the whole working process is automatically completed by PLC program control executive components.

[0014] The setting direction of the traction cylinder 3 of the trolley 2 is consistent with the copper disc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com