Off-line debugging apparatus and off-line debugging method of blast-furnace gas glasses valve control loop

A technology of valve control and blast furnace gas, which is applied to blast furnaces, blast furnace details, furnaces, etc., can solve problems such as unrealistic, time-consuming, cumbersome dismantling and installation work, and achieve fast and reliable debugging and reduce time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

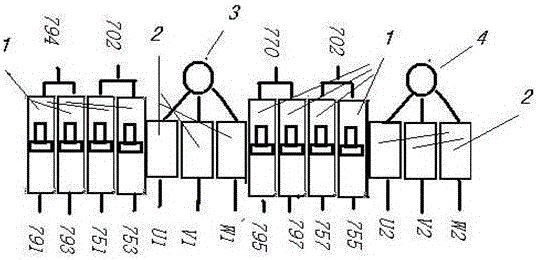

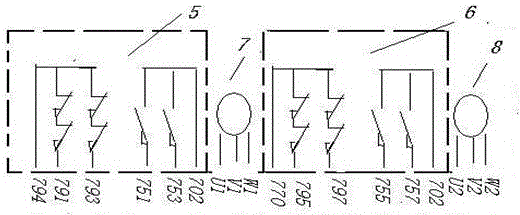

[0025] Example 1: An off-line debugging device for the control loop of the blast furnace gas eye valve

[0026] An off-line debugging device for the control circuit of blast furnace gas eye valve, including single-pole switches F1-F8, three-phase phase sequence table X1 and three-phase phase sequence table X2; single-pole switches F1-F8 are respectively used for the opening position of the plate moving device , the closing position of the pallet moving device, the light on control of the pallet running device, the light off control of the pallet running device, the clamping control of the unclamping / clamping device, the loosening control of the unclamping / clamping device, the unclamping / clamping The clamping light control of the tightening device and the unclamping light control of the unclamping / clamping device; the three-phase phase sequence table X1 respectively connects the U1, V1, W1 terminals of the main circuit power supply of the board motor, and the three-phase phase s...

Embodiment 2

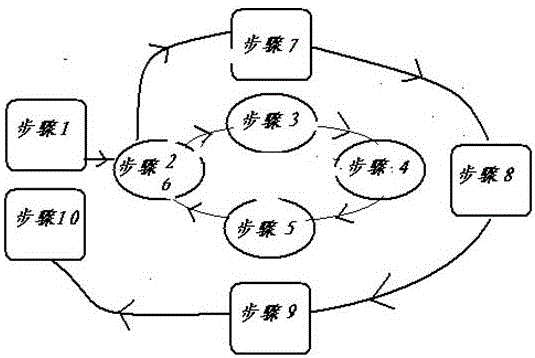

[0027] Embodiment 2: A debugging method for the device described in Embodiment 1

[0028] A debugging method for the off-line debugging device of the blast furnace gas eye valve control loop described in technical solution 1, comprising the following steps:

[0029] Step 1: Close terminal 757, disconnect terminal 755, disconnect terminal 797, close terminal 795, disconnect terminal 791, 793, 751, and 753, check whether the computer and local signal display are normal, and loosen / clip Check whether the clamping device is in the loosening position; if yes, turn to step 2, otherwise check the control circuit of the releasing / clamping device and troubleshoot;

[0030] Step 2: Close terminal 751, disconnect terminal 753, disconnect terminal 791, close terminal 793, and judge whether the computer and local signals show that the board feeding device is in the open position. If so, turn to step 3, otherwise check the board feeding control circuit and troubleshoot;

[0031] Step 3: C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com