Low-speed intermittent rotating mechanism and working method thereof

A slewing mechanism, low-speed technology, applied in the direction of mechanical equipment, belts/chains/gears, transmissions, etc., can solve the problems of poor stability and reliability, low efficiency, unchangeable sheave structure, etc., to achieve stability and reliability Good, easy to use, high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

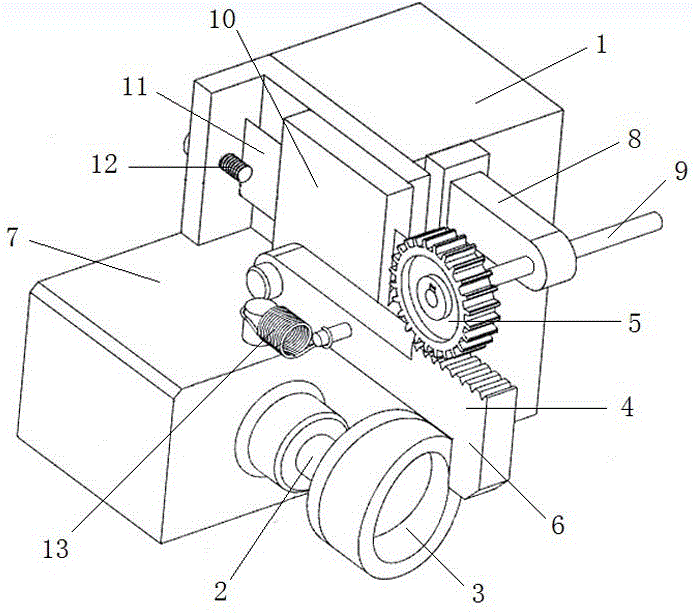

[0013] Such as figure 1 As shown, a low-speed intermittent rotary mechanism includes a seat body 1, on which there is a camshaft 2 driven by a driving device, the end of the camshaft 2 is eccentrically provided with an eccentric end cam 3; the eccentric end cam 3 is provided with a The rack 4 that can swing up and down and move back and forth is located above the rack 4 and is provided with a gear 5 that meshes with the rack 4 when it swings up; Fitted hook 6, when the eccentric end cam 3 rotates away from the axis to the upper side, it pulls the rack 4 to swing upwards, and the protruding contour on the end surface of the eccentric end cam pushes the rack 4 forward to drive the gear 5 to rotate When the eccentric end face cam 3 rotates downward away from the side of the axis, the rack 4 will also swing downwards due to its own weight to break away from the gear 5 and fall on the support platform 7 of the seat body to limit its continued hem; the end face of the eccentric end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com