A method for detecting abnormal points in heat meter durability cold and heat shock test

A technology of durability test and thermal shock, applied in the field of instrument anomaly detection, it can solve the problems of long durability test process, economic loss, and large flow cycle change span.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

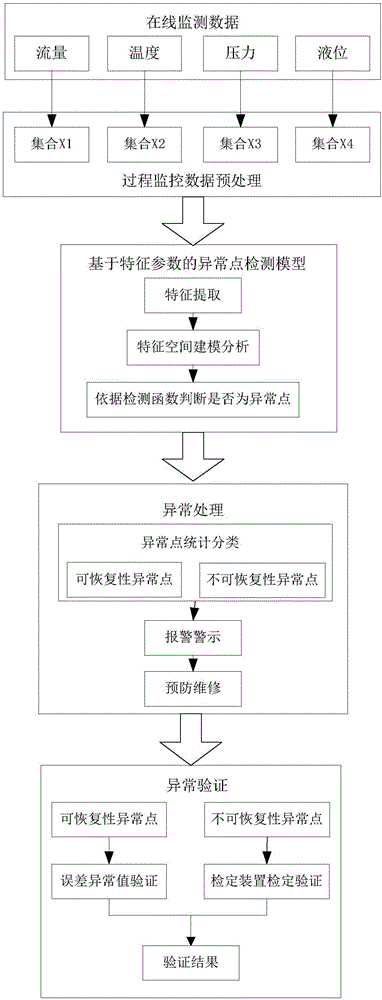

Method used

Image

Examples

test approach 3

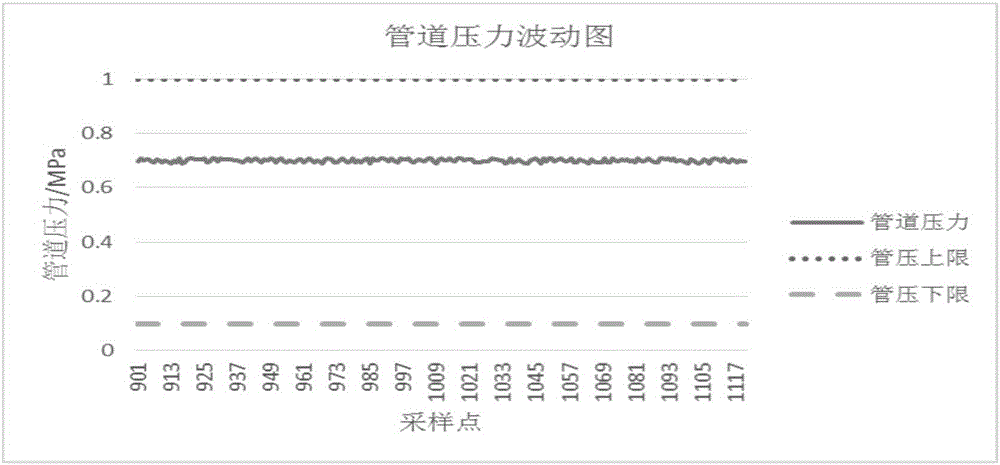

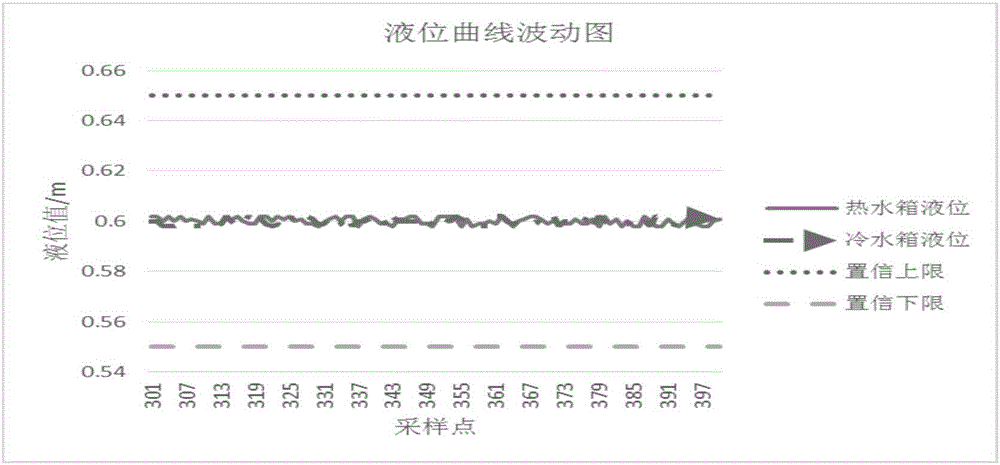

[0125] Among them: f(μ, σ, max, min, Med, Desc, Asc) is the abnormal point detection function, 1 means normal, 0 means abnormal, E 3 For test method 3, that is, the set of all characteristic parameters under 4000 thermal shock tests, X 3 is the current feature parameter set under test method 3;

[0126] E3=(O GYmax ∩O GYmin )∩(O SWmax ∩O SWmin )∩(O CLSmax ∩O CLSmin ∩O LELS1 ∩O LELS2 )

[0127] ∩(O LJ )∩((O GLGWG ∩O GLGWD ∩O GLGWC )∪(O GLDWG ∩O GLDWD ∩O GLDWC ))

[0128]If the detection data result is abnormal, all the eigenvalues of the abnormal points are obtained, and all the eigenvalues of the abnormal points are added to the abnormal data set. The abnormal data set records the process state parameters using different feature extraction methods under different working conditions. The collection of detected outliers, according to whether the outliers appear continuously in the continuous sampling period, the outliers can be divided into two cases: the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com