Method for detecting abnormal value during durability test process of calorimeter

A technology of durability test and detection method, applied in the field of instrument testing, can solve problems such as hidden dangers of personnel safety, economic loss, and inability to fully meet the requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

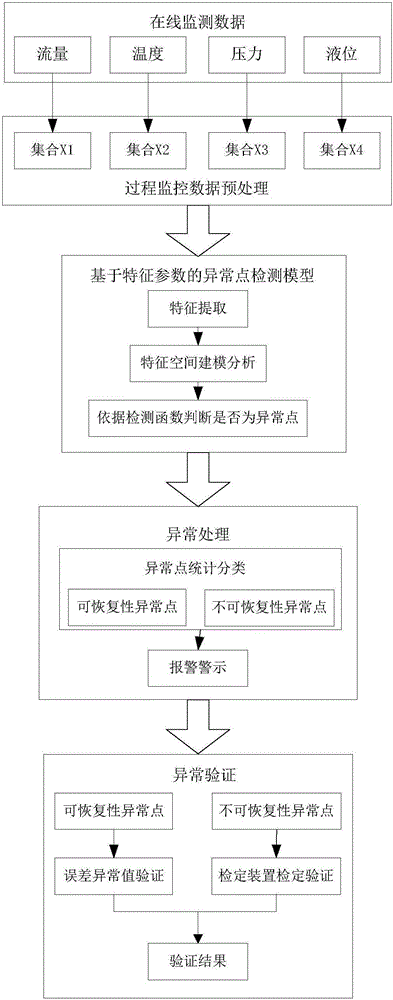

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

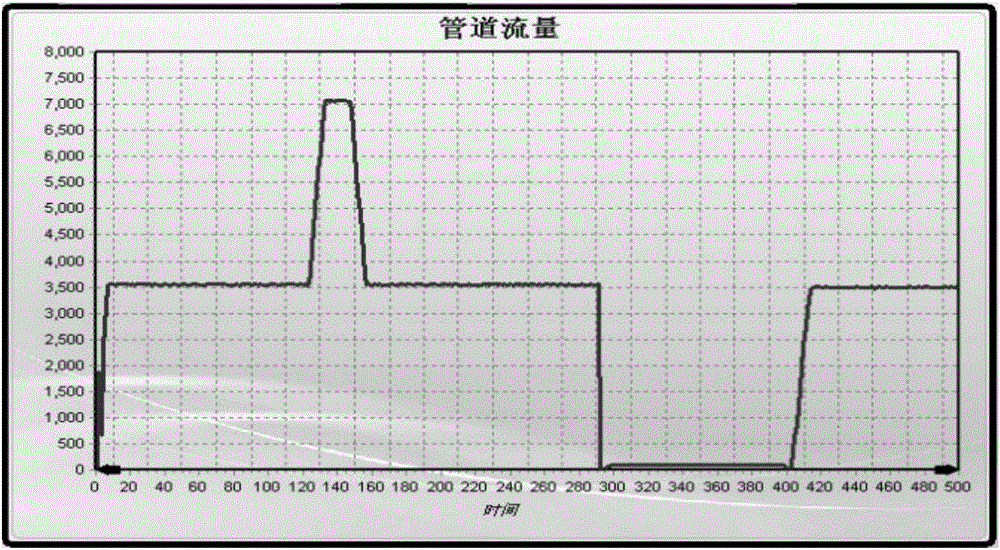

[0179] When using the heat meter durability test device of this embodiment to carry out the 2400h basic durability test on the heat meter, the selected heat meter is a grade 3 DN25 heat meter, and the detection of the abnormal point of the process failure is realized by the following steps:

[0180] (1) Take the sampling period t s = 5s is the state parameter of the durability test process for the heat meter at intervals;

[0181] (2) Establish a data set of test process state parameters, record the current sampling times as k, k≥1; sampling time t=kt s ; Take t1=900s~5900s, t2=29700s~30600s, t3=1067400s~1071000s as an example for analysis.

[0182] (3) To each test process state parameter data set collected in step (2), carry out state parameter feature extraction;

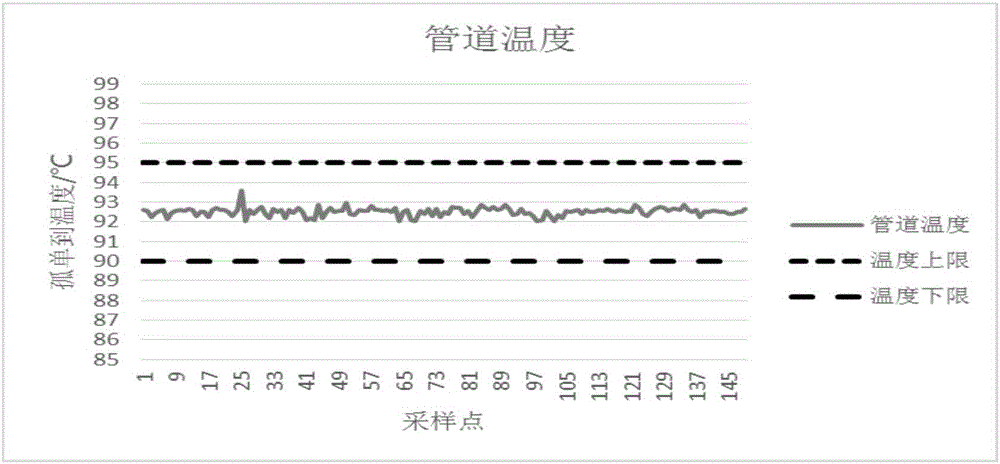

[0183] (4) When judging the state of the water flow system, according to European durability standards and my country's heat meter standards, the 2400h basic durability test keeps the water temperature in the s...

Embodiment 2

[0240] For the abnormal point detection of the 300h additional durability test, its steps (1), steps (2), and steps (3) are the same as in Example 1; in step (4), the instantaneous flow rate of the water flow in the pipeline is constant and remains at q s =7000L / h remains unchanged, the temperature is constant, and kept at T=θ max -5℃~θ max a constant value between. In step (5), the pipeline water temperature, pressure, and water tank liquid level are also consistent with the model of embodiment 1; when flow modeling is similar to the state 1 modeling in embodiment 1, the measured heat meter and standard flow meter Instantaneous flow q c Does it satisfy the set O CLPmax ∩O CLPmin , check whether the standard flow meter meets O LELP1 , check whether the detected heat meter satisfies O LELP2 : Cumulative flow q of the heat meter to be tested Le2 satisfies the set O LJ , the accumulated heat Q of the heat meter under test Le2 satisfies the set O RL .

[0241] According...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com