Oscillating bar type spring pre-resetting die mechanism

A technology of mold mechanism and rod spring, which is applied in the field of swing rod spring first reset mold mechanism, which can solve the problems of mold damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

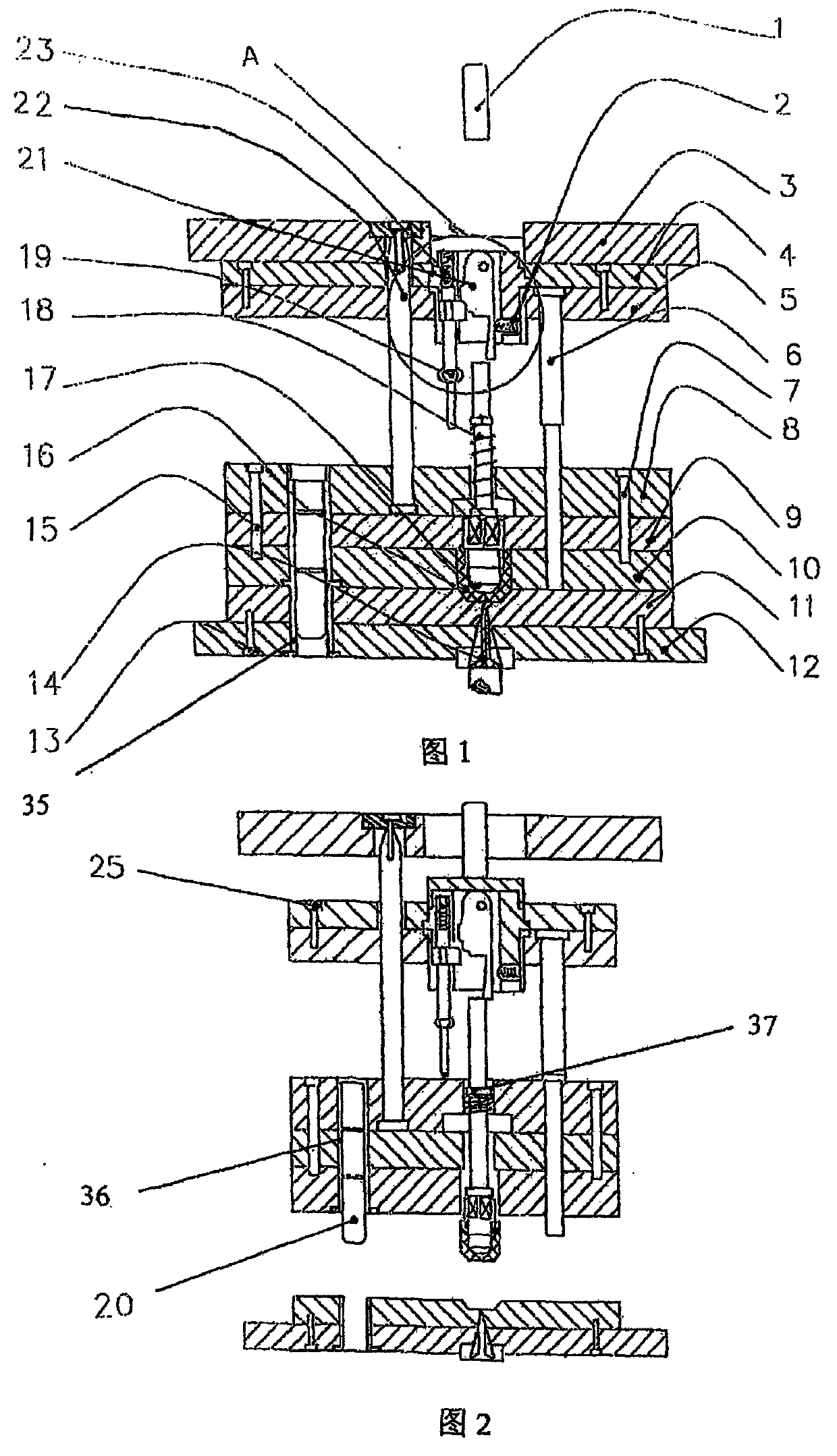

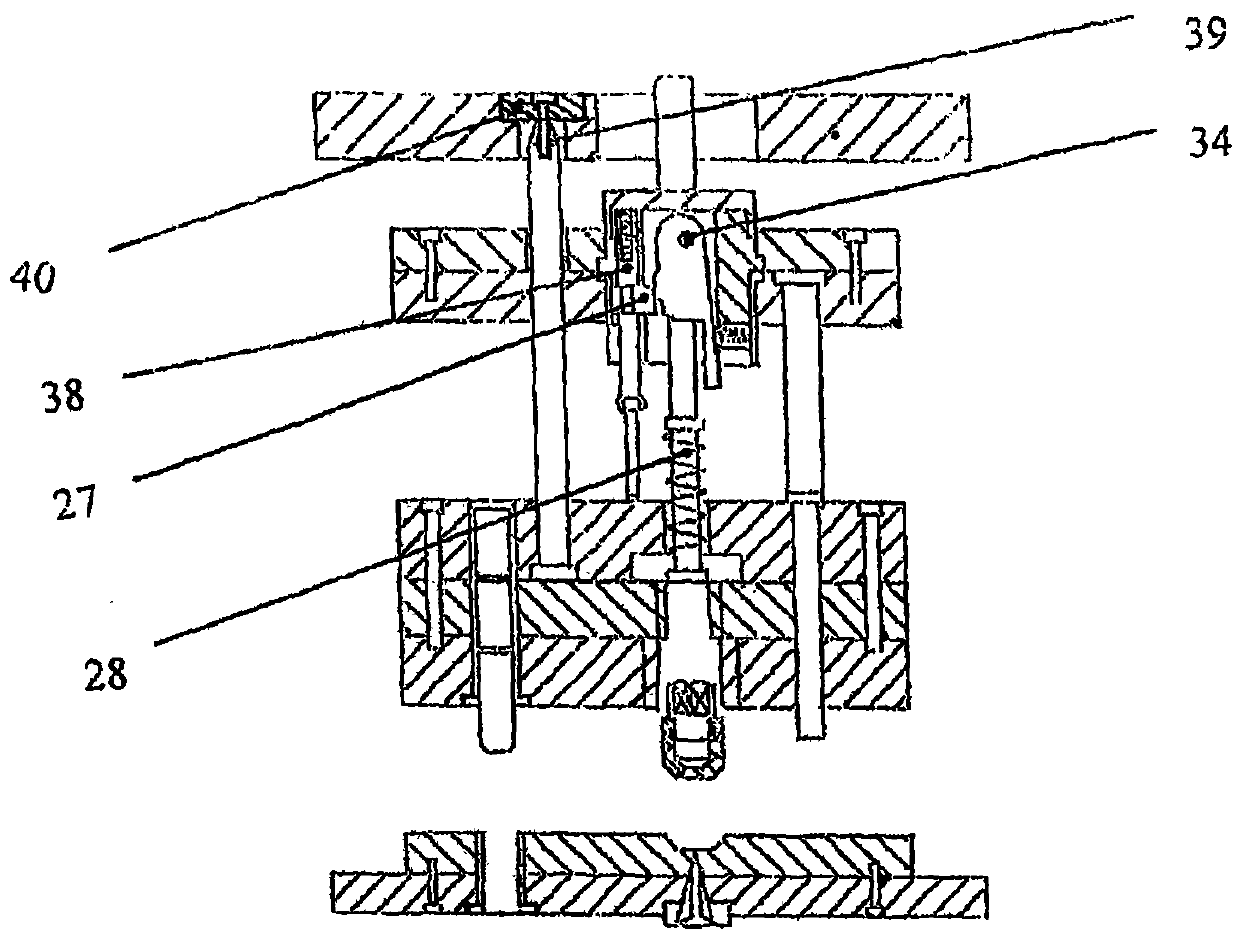

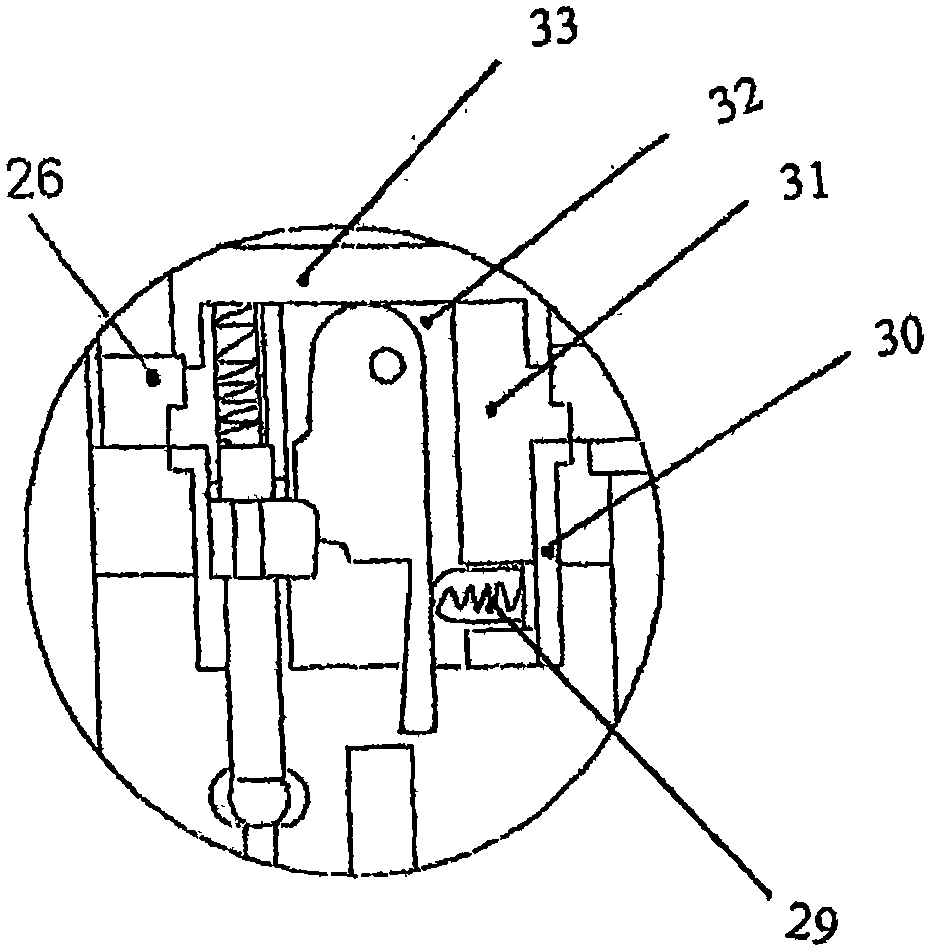

[0024]As shown in the figure, the swing rod type spring first resets the mold mechanism. After the mold is opened, during the ejection process, the swing rod (21) pushes the push rod (18) to push out the threaded core (17) together with the product (16). When continuing to push out, the third guide post (6) is blocked, and the bushing (19) is used to push the projection (27) to force the swing rod (21) to swing, so that the end face of the swing rod (21) breaks away from the position of the push rod (18). State, at this moment, make push rod (18) reset under the first spring (28) effect; Like this just can pack into thread core (17). When closing the mould, because the third guide post (6) resets the ejector mechanism, during the reset process, when reset to a certain distance, the bump (27) enters the swing rod (21) under the action of the second spring (23). ) of the concave platform, while the swing rod (21) swings to the center of the mold under the promotion of the third ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com