Liquid feeding missing and liquid sucking missing detection apapratus

A detection device and liquid leakage technology, applied in the direction of analyzing materials, instruments, etc., can solve the problems of easy negligence and mistakes by personnel, waste of sample reagents and time, and difficulty in identifying errors by personnel, so as to save the cost of personnel process monitoring and improve reliability. and safety, the effect of avoiding medical risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

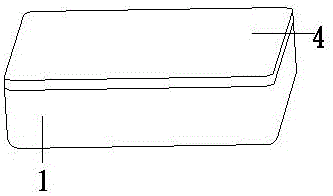

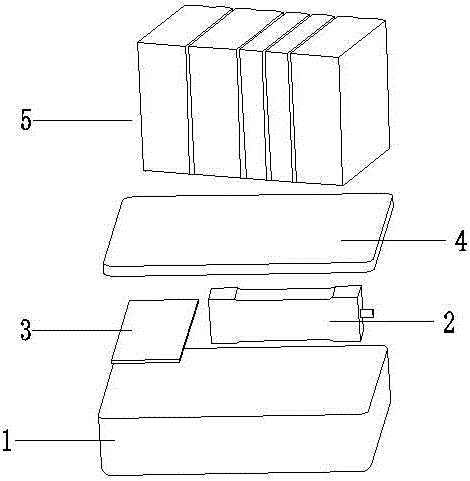

[0012] Such as figure 1 with figure 2 As shown, an embodiment 1 of a detection device for leakage of liquid addition and leakage of suction includes a box-shaped base 1, a load cell 2, a control board 3, an induction board 4 and a liquid container 5, wherein:

[0013] The box-shaped base 1 shown is located below the load cell 2, the load cell 2 is fixed on the inner upper surface of the box-shaped base 1, and a control board 3 is arranged on the left side of the load cell 2 , the control board 3 has COM, USB, and IP communication interfaces, is fixed on the inner upper surface of the box-shaped base 1, and an induction board 4 is set above the box-shaped base 1, and the induction board 4 is covered On the upper end surface of the box-shaped base 1, N liquid containers 5 are arranged above the induction plate 4;

[0014] During the liquid suction process, the load cell 2 senses the weight change of the liquid container 5 before and after liquid suction through the induction ...

Embodiment 2

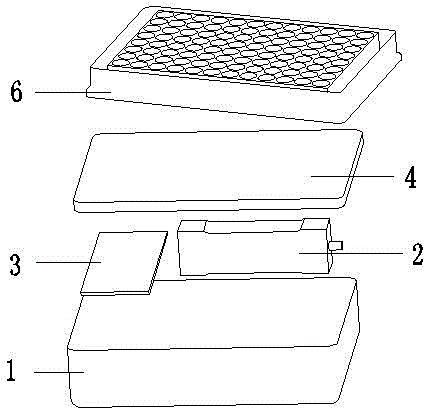

[0016] Such as figure 1 with image 3 As shown, an embodiment 2 of a detection device for leaking liquid addition and leaking liquid suction includes a box-shaped base 1, a load cell 2, a control board 3, an induction board 4 and a microboard 6, wherein:

[0017] The box-shaped base 1 shown is located below the load cell 2, the load cell 2 is fixed on the inner upper surface of the box-shaped base 1, and a control board 3 is arranged on the left side of the load cell 2 , the control board 3 has COM, USB, and IP communication interfaces, is fixed on the inner upper surface of the box-shaped base 1, and an induction board 4 is set above the box-shaped base 1, and the induction board 4 is covered On the upper end surface of the box-shaped base 1, a microplate 6 is arranged above the induction plate 4;

[0018] During the liquid addition process, the load cell 2 senses the weight change of the microplate 6 before and after the liquid addition through the induction plate 4 to jud...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com