Main transformer and high voltage side cable zero-sequence differential protection polarity test circuit and method

A main transformer, polarity test technology, applied in the direction of instruments, measuring electricity, measuring electrical variables, etc., can solve the problems of inability to check the polarity correctness of zero-sequence differential protection devices, economic losses, malfunction and tripping, etc. The effect of preventing misoperation of zero-sequence differential protection and ensuring correctness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

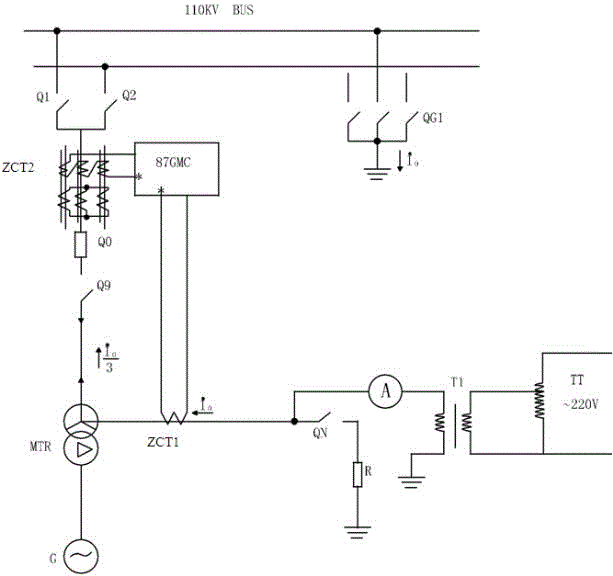

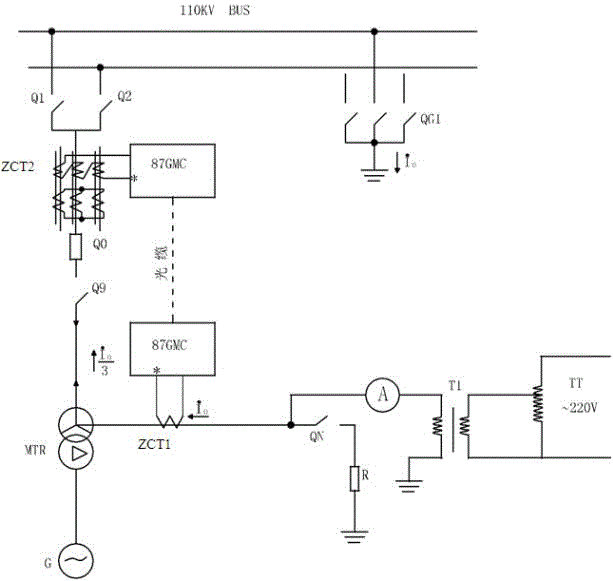

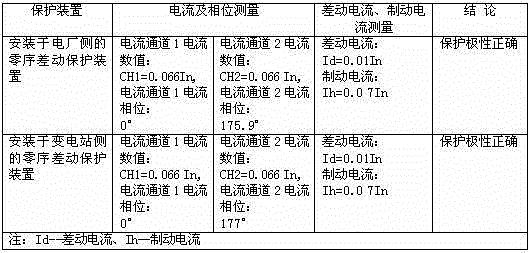

[0030] A factory imported a 350MW generator-transformer system, and installed an optical fiber differential main transformer and high-voltage side cable zero-sequence differential protection. According to the test circuit and test method of the present invention, the main transformer and high-voltage side cable zero-sequence differential For testing, see figure 2 , 40A current is injected from the front end of the neutral point grounding switch QN of the main transformer, and the data measured from the inside of the protection device 87GMC are shown in Table 1:

[0031] Table 1

[0032]

[0033] According to the test method of the present invention, the above-mentioned table 1 test data is analyzed, and it can be judged that the polarity of the main transformer and the high-voltage side cable zero-sequence differential protection device 87GMC is wrong, and after changing the wiring of the zero-sequence current transformer ZCT circuit on one side, The test was carried out ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com