An integrated installation method of a separation device and a printed circuit board

A technology of printed circuit board and installation method, which is applied in the direction of assembling printed circuit with electrical components, printed circuit, printed circuit manufacturing, etc. The effect of improving efficiency and installation accuracy, improving resistance to mechanical environment, and improving reliability of solder joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

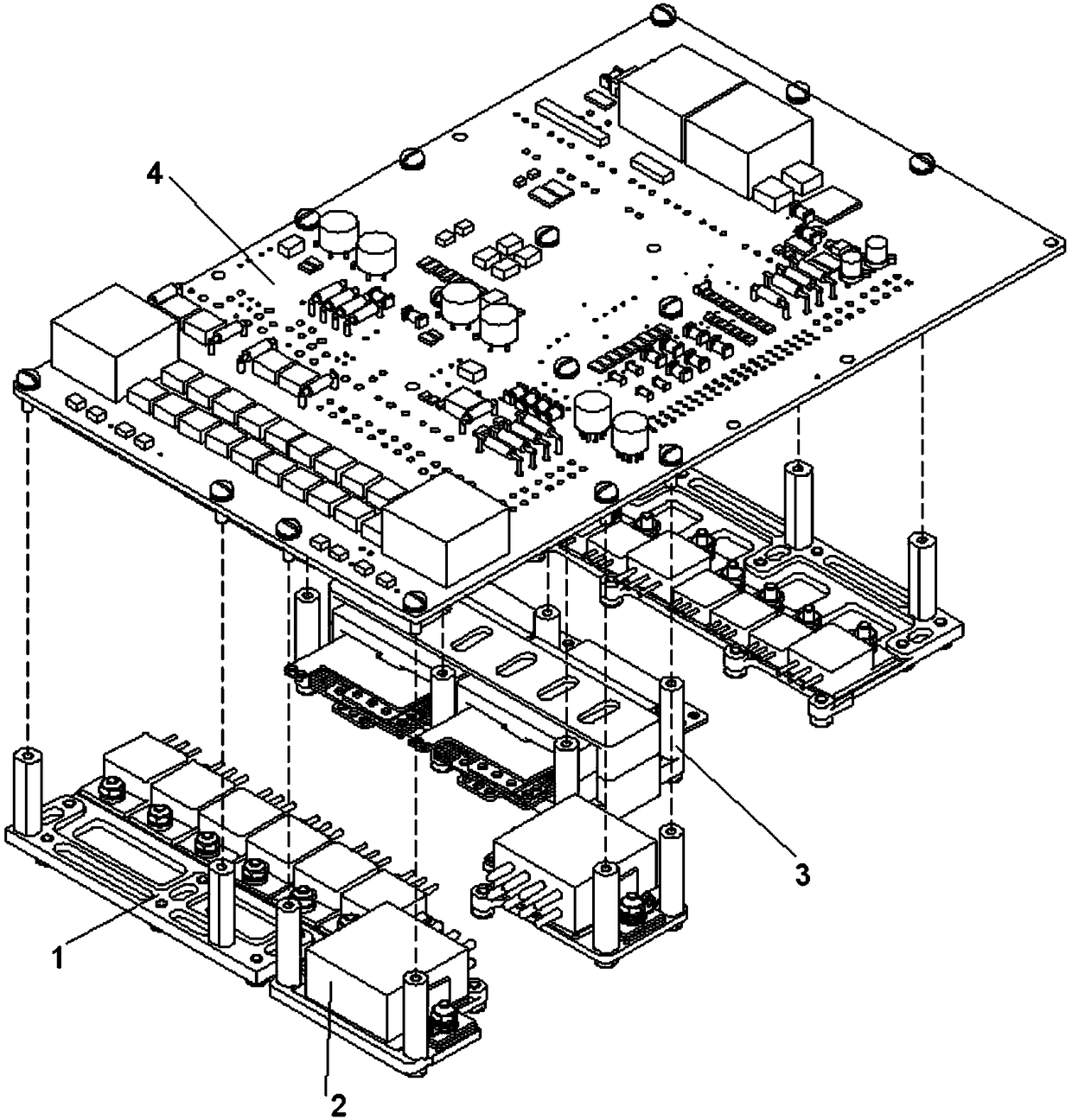

[0037] Such as figure 1 As shown, the integrated installation of the separation device and the printed circuit board includes: the integrated installation assembly 1 of the TO package device, the integrated installation assembly 2 of the EL relay, and the installation of the integrated installation assembly 3 of the E-type planar transformer.

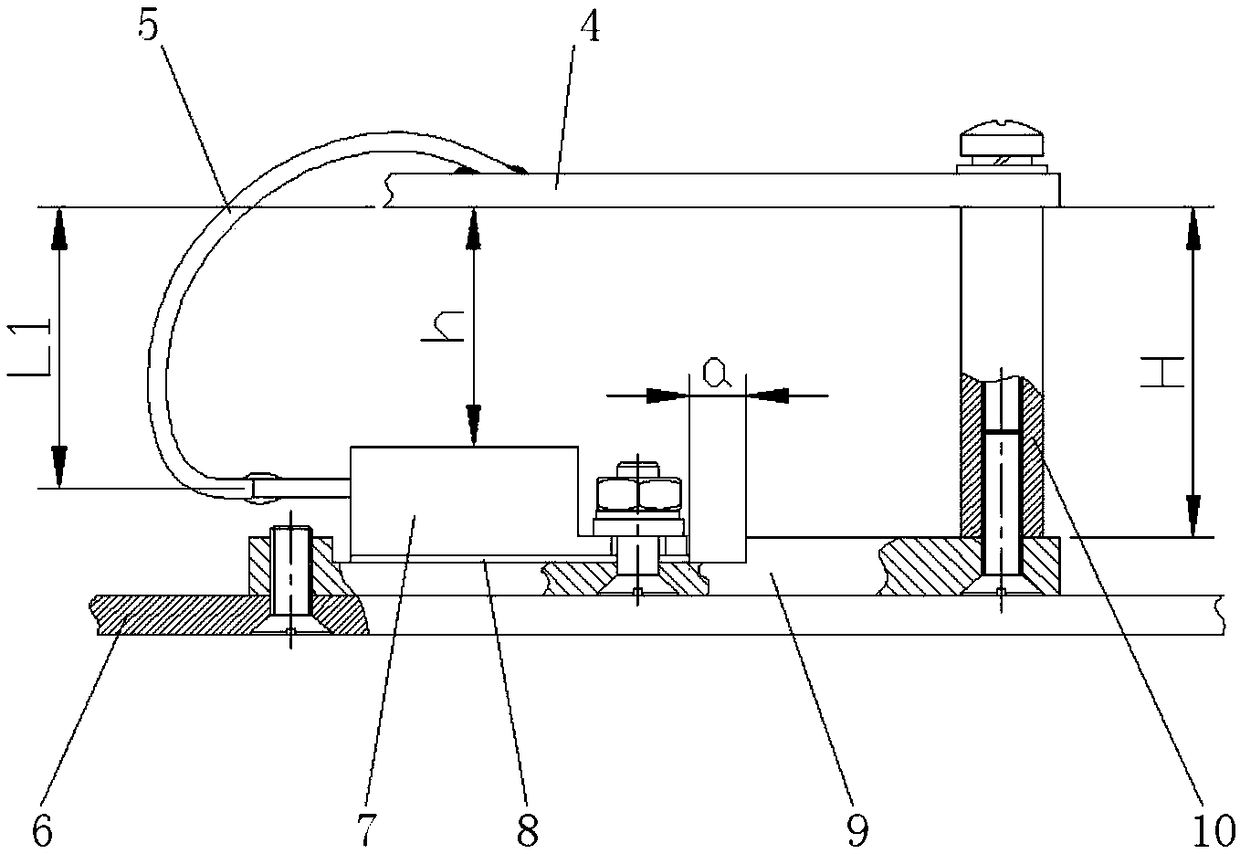

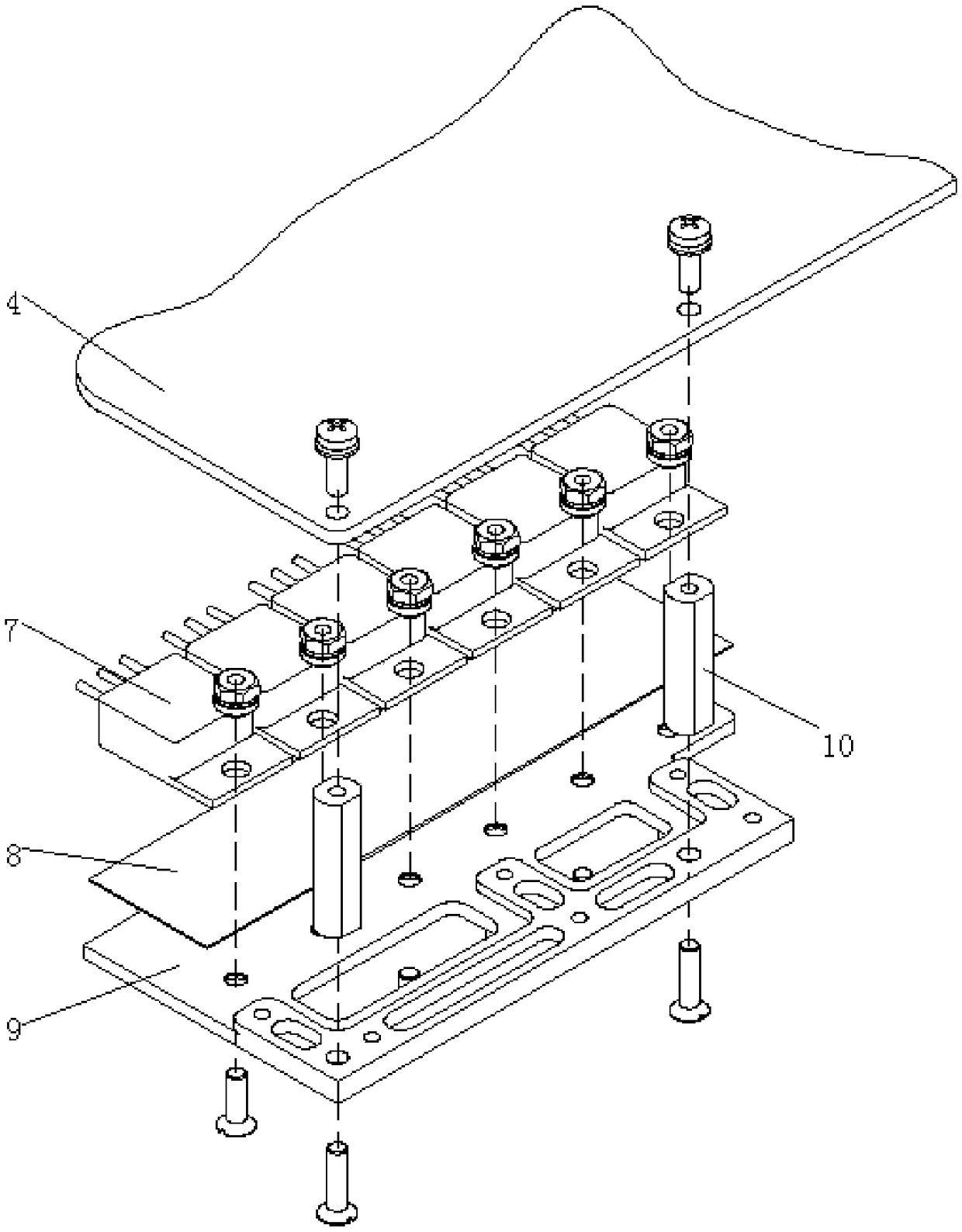

[0038] Such as figure 2 , image 3 As shown, the TO packaged device integrated installation assembly 1 includes: TO packaged device 7, heat conduction pad and heat conduction filler 8, pedestal 9, support column 10 (detachable);

[0039] Such as Figure 4 , Figure 5 As shown, the E-type planar transformer integrated installation assembly 3 includes: heat conduction pad and heat conduction filler 8, transformer cushion 11, transformer pressure plate 12, single-component vulcanized silicone rubber 13, and E-type planar transformer 14;

[0040] Such as Image 6 , Figure 7 As shown, the EL-type relay integrated installation assembl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com