Pneumatic tire

A technology for pneumatic tires and tires, which is applied to pneumatic tires, special tires, tire parts, etc., can solve the problems of lower ground pressure, worse ground handling stability, and shorter ground contact length, etc., to improve handling stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

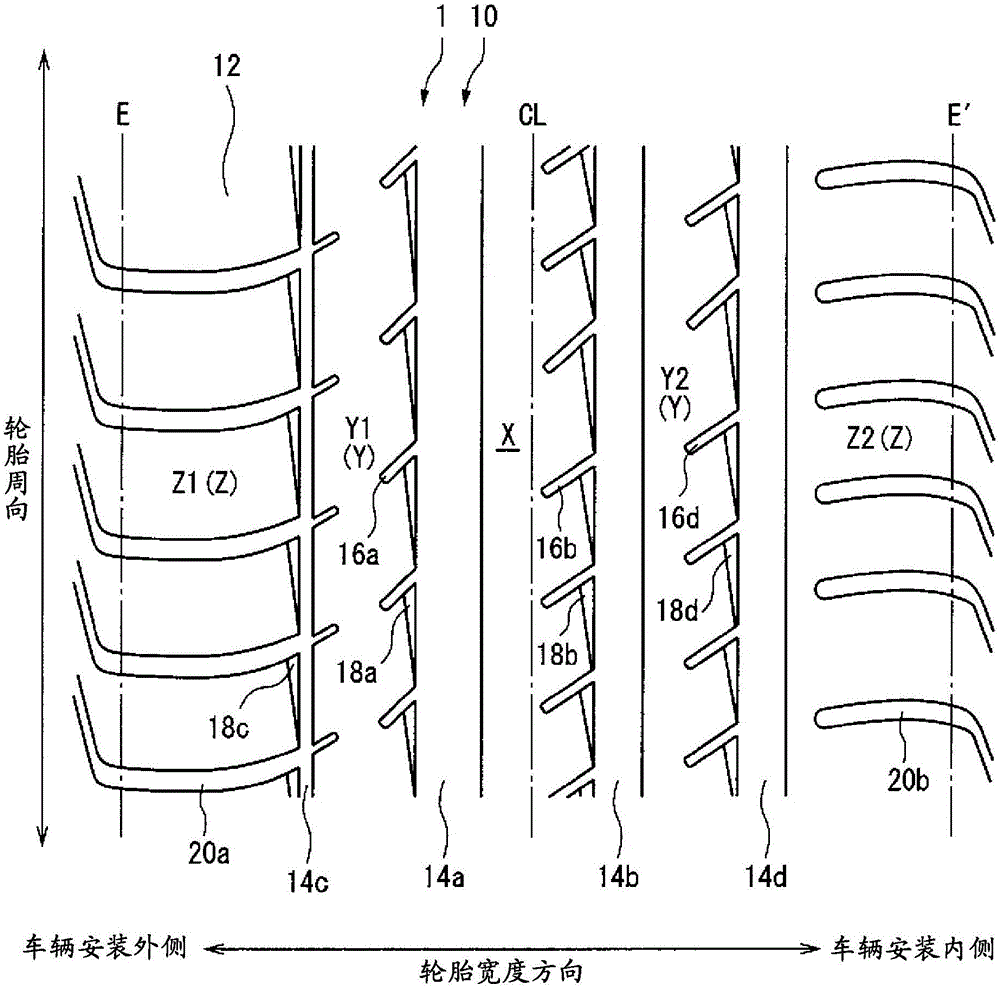

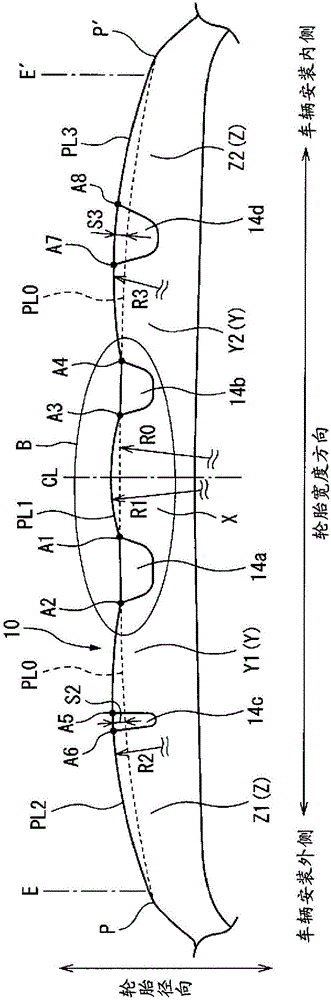

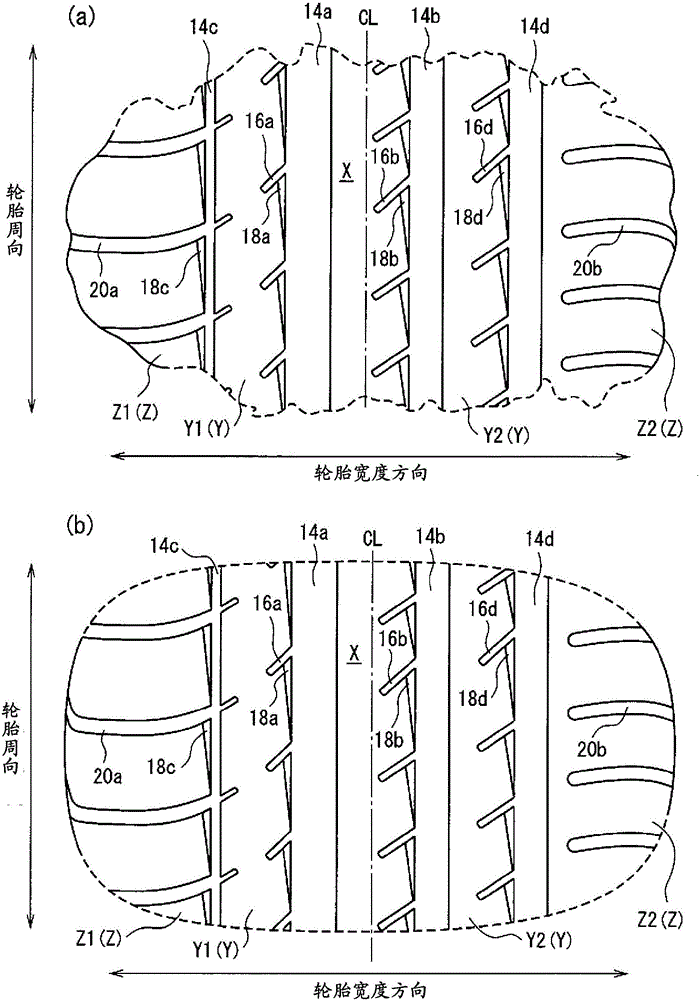

[0076] Set the tire size to 235 / 40ZR18 (95Y), make a figure 1 The tread pattern shown approximates the tread pattern and has figure 2 ( Figure 4 ) of the tread surface contour lines PL1, PL2, PL3 of the pneumatic tires of Examples 1 to 7. In addition, the various conditions at the outline details of the tread surfaces of the pneumatic tires of Examples 1 to 7 are as shown in Table 1 below.

[0077] On the other hand, the tire size was set to 235 / 40ZR18 (95Y), and the pneumatic tire of the conventional example was produced, except figure 2 The pneumatic tire of Conventional Example has the same structure as the pneumatic tire of Example 1 except that the contour lines PL1 , PL2 , and PL3 of the tread surface shown coincide with the reference contour line PL0 ′.

[0078] Each test tire of Example 1 to Example 7 and the conventional example produced in this way was assembled on a rim of 18 x 8.5J, and the air pressure was set to 230kPa, and installed on a passenger car with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com