Device for cleaning roller surfaces of a drafting system device

A drafting and stripping device technology, applied in drafting equipment, textiles and papermaking, spinning machines, etc., can solve problems such as accumulation, affecting drafting operation, uneven fiber sliver, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

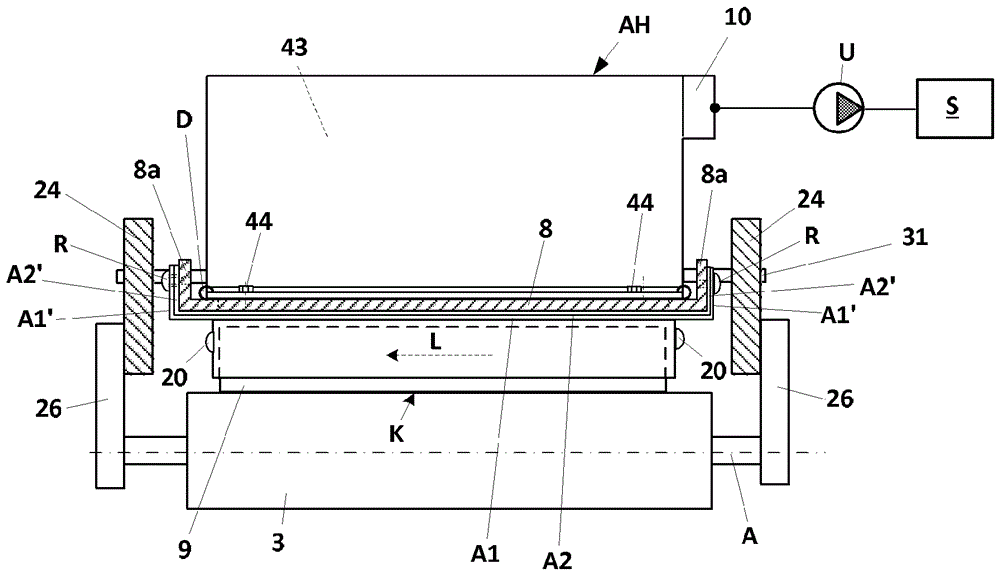

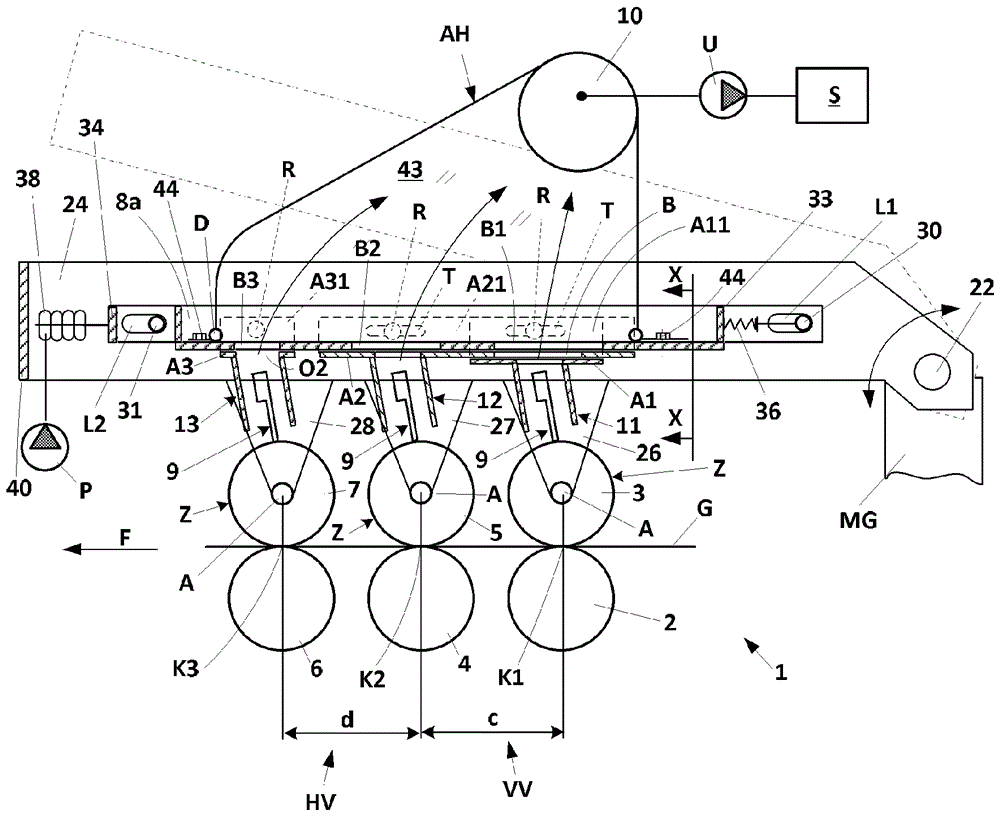

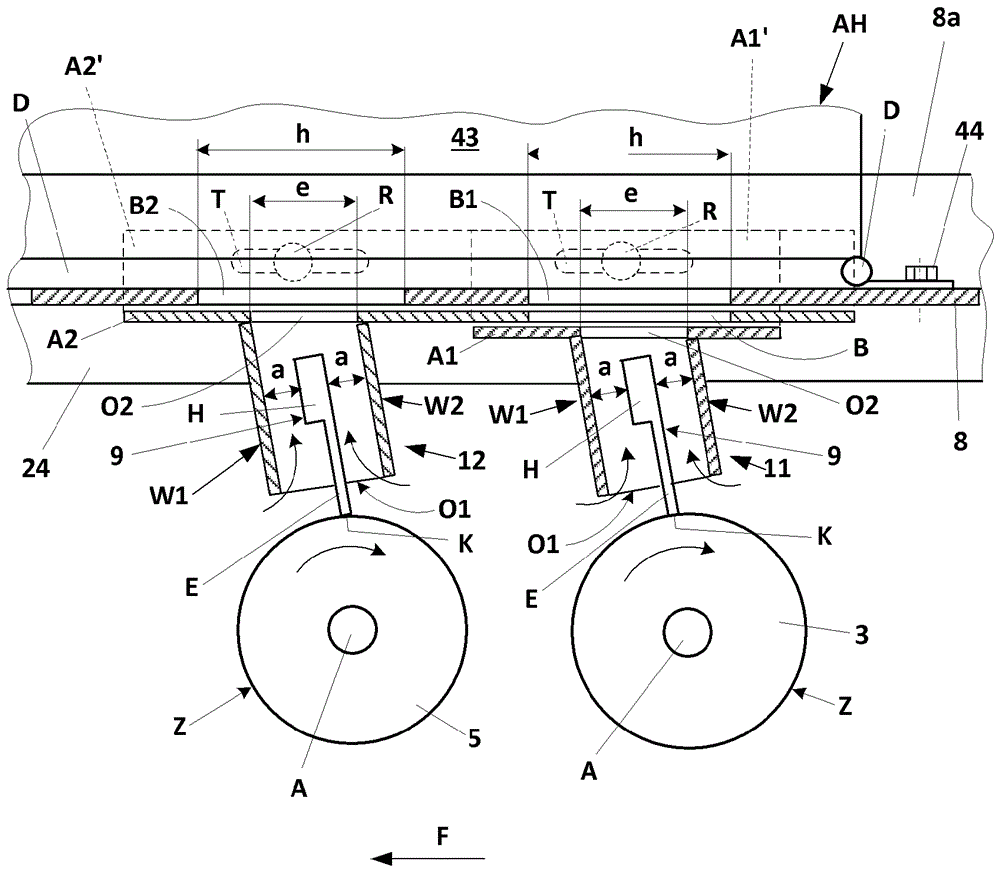

[0034] figure 1 Shows a schematic side view of the drafting system 1 equipped with roller pairs 2, 3; The fibrous material G is processed in zone HV. Here, the fibrous material G to be drawn is moved in the conveying direction F through the drafting system 1 . The lower rollers 2 , 4 , 6 , which are connected to a drive mechanism not shown, are generally embodied as profiled steel rollers and are rotatably mounted in the machine frame MG. The upper rolls 3, 5, 7 (also called pressure rolls) assigned to the lower rolls typically have a rubberized surface (circumferential surface) Z and are pressed against the appropriately assigned lower rolls 2, 4 during operation by means not shown Or 6 in order to form clamping positions K1, K2, K3. The upper rollers 3, 5, 7 are rotatably mounted via axis A in bearings 26, 27, 28 and are driven by friction by the respective lower rollers 2, 4, 6 cooperating therewith. Bearings 26 , 27 , 28 arranged on respective ends of the upper rollers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com