Transformer iron core mute testing system

A test system and transformer technology, applied to TV system components, instruments, measuring devices, etc., can solve the problems of simple instruments, unauthoritative test data, large deviation between test results and real values, etc., and achieve convenient operation , compact structure and accurate test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

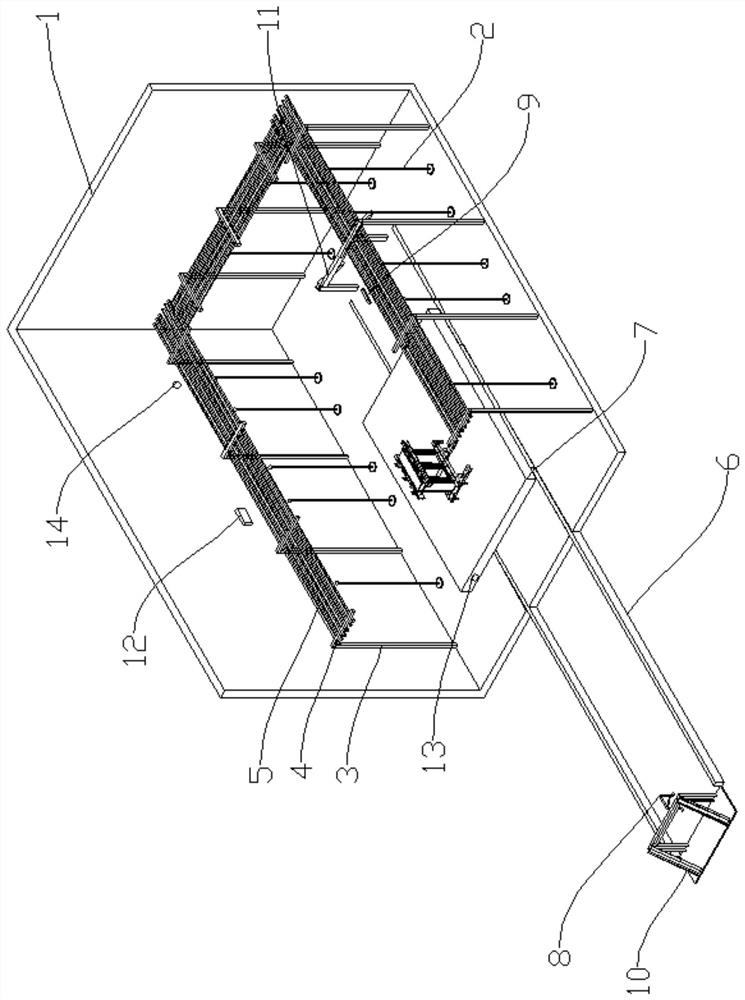

[0022] Such as figure 1 In the shown embodiment, a transformer core silent test system mainly includes a quiet room 1 , the side walls of the quiet room 1 are made of sound-insulating materials, so as to avoid the influence of external environmental noise on the environment inside the quiet room 1 .

[0023] Such as figure 1 In the shown embodiment, a channel for the transformer core to enter and exit is provided on one side of the silent room 1, and a sound insulation door is provided at the channel opening. A transport track 6 is set inside and outside the channel of the silent room 1 , and a transport trolley 7 is arranged on the transport track 6 , and the transport trolley 7 can move in and out of the silent room 1 along the transport track 6 .

[0024] The transformer core to be tested is carried on the transport trolley 7, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com