Low-profile bidirectional locking large-angle universal pedicle screw

A pedicle screw and low-profile technology, applied in the field of pedicle screws, can solve the problems of inability to spread and compress, small universal mobility, difficult to connect rods, etc., and achieve firm and reliable locking and low difficulty in screw placement. , the effect of low adverse complications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

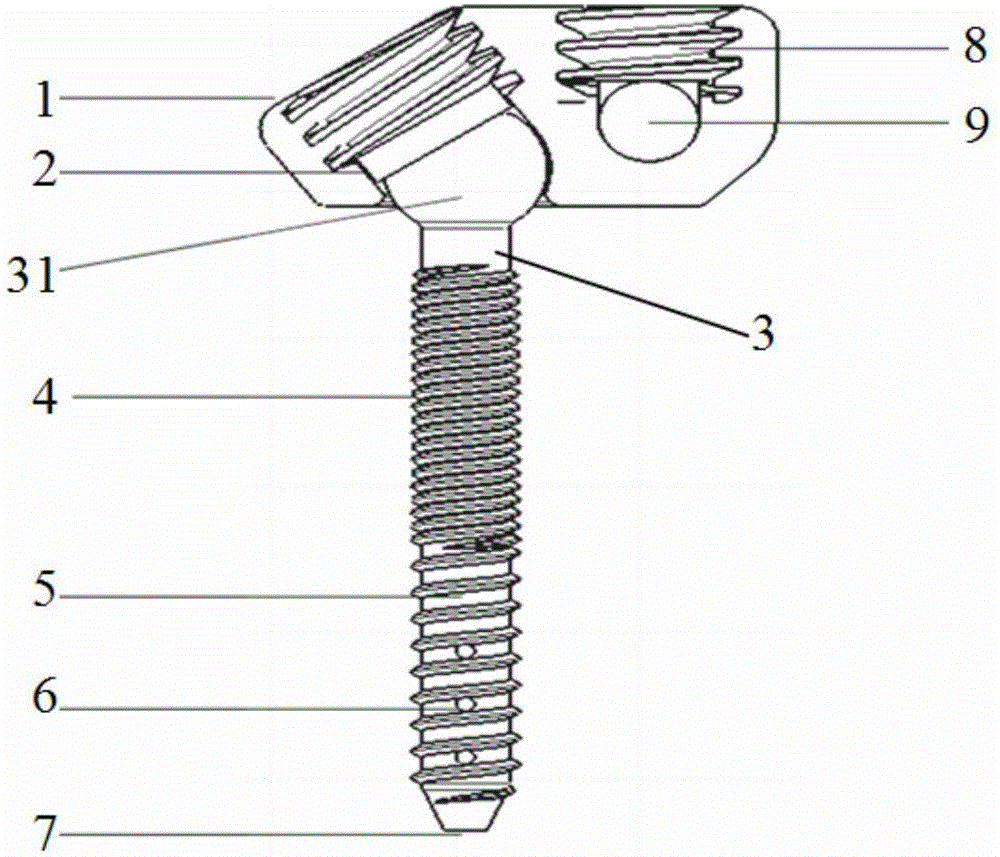

[0016] see figure 1 , Embodiment 1 of the present invention is provided with nail cap 1 and nail body 3, and the spherical nail head 31 side of nail body 3 is provided with U-shaped groove 9, and nail body 3 is hollow nail body, and the proximal end of nail body 3 is provided with near end thread 4, the distal end of the nail body 3 is provided with a distal thread 5, the depth of the proximal thread 4 is less than the depth of the distal thread 5, the distal thread 5 is provided with a through hole 6, and the distal thread 5 is used for injecting bone Cement, the end of the nail body 3 is provided with a hole 7, the hole 7 is used to inject bone cement, a nail cap and nail body two-way locking device 2 is provided between the nail cap 1 and the nail body 3, and a locking nut is provided on the U-shaped groove 9 8. The locking nut 8 is used for locking the U-shaped groove 9 and the connecting rod.

[0017] The nut 1 adopts a low profile nail cap.

[0018] U-shaped groove 9 i...

Embodiment 2

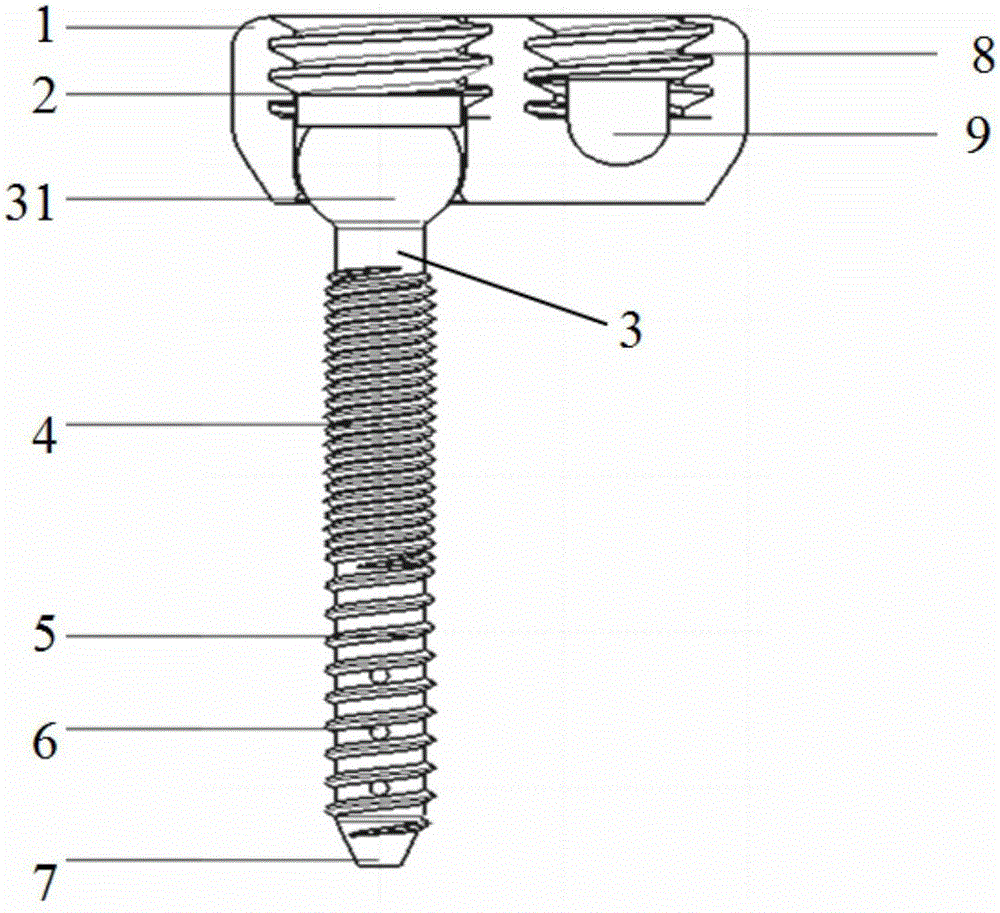

[0023] see figure 2 , similar to Embodiment 1, the difference is that the locking of the spherical nail head 31 of the nail body 3 and the nail cap 1 is locked by a large-sized nut, and the locking nut is larger in size, and the locking effect is better. At the same time, the U-shaped groove 9 and the connecting rod are locked and fastened by the locking nut 8 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com