Method for manufacturing Cr-Ni-Mo-Nb nickel base alloy seamless tube

A technology of nickel-based alloy and manufacturing method, applied in the field of nickel-based alloy preparation, can solve problems such as cracking, and achieve the effect of overcoming the inability to cold-draw deformation and avoiding the problem of extrusion and delamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

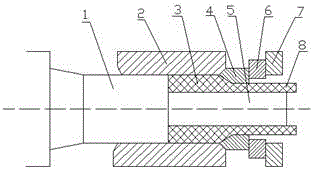

Image

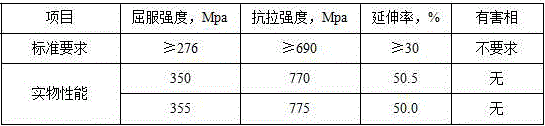

Examples

Embodiment 1

[0051] The design process for the finished product specification Φ25×2mm is as follows:

[0052]Tube blank preparation (Φ219mm) → hot extrusion (Φ140×12mm) → straightening → sawing → pickling → cold rolling (Φ114×10mm) → degreasing → heat treatment → straightening → sawing → pickling → cold rolling (Φ89 ×7mm) → degreasing → heat treatment → straightening → sawing → pickling → cold rolling (Φ57×5mm) → degreasing → heat treatment → straightening → sawing → pickling → cold rolling (Φ38×3mm) → degreasing → heat treatment → Straightening → sawing → pickling → cold rolling (Φ25×2mm) → degreasing → heat treatment → straightening → sawing → pickling → flaw detection → storage

[0053] The specific process is as follows:

[0054] (1) tube blank

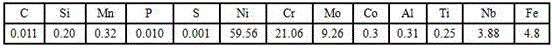

[0055] It adopts forged and lathe-finished tube billets, and the specification is Φ219mm. The composition of the tube blank is as follows:

[0056]

[0057] (2) Blank preparation

[0058] Saw the forged tube billet into a 650mm / piece b...

Embodiment 2

[0110] The design process for the finished product specification Φ250×8mm is as follows:

[0111] Raw material preparation (Φ306mm) → hot extrusion (Φ194×22mm) → straightening → sawing → pickling → grinding → lubrication → cold rolling (Φ168×15mm) → degreasing → heat treatment → straightening → sawing → pickling → Lubrication → cold expansion (Φ250×14mm) → degreasing → heat treatment → straightening → sawing → pickling → lubrication → cold rolling (Φ219×8mm) → degreasing → heat treatment → straightening → sawing → pickling → lubrication → cold expansion (Φ250×8mm) → degreasing → heat treatment → straightening → sawing → pickling → flaw detection → storage

[0112] The specific process is as follows:

[0113] (1) tube blank

[0114] The forged tube blank is used, and the specification of the tube blank is Φ306mm. The composition of the tube blank is as follows.

[0115]

[0116] (2) Blank preparation

[0117] Saw the forged tube billet into 600mm / piece billets, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com