Line drawing instrument for metal sheets

A metal sheet and positioning clip technology, applied in the field of mechanical processing, can solve problems such as skewed lines, shallow traces, and estimated values

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

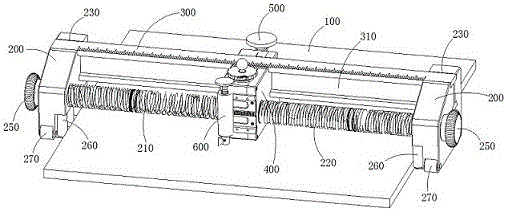

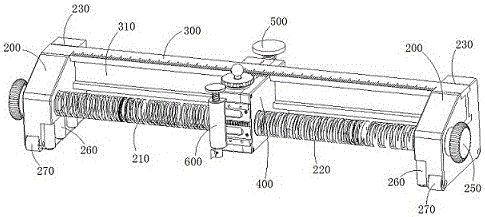

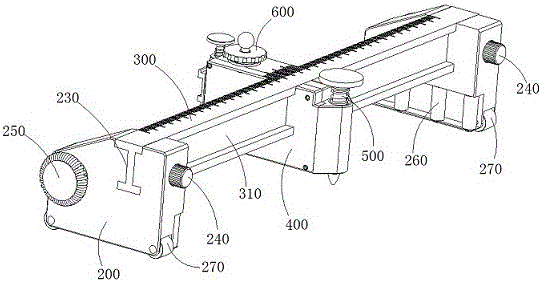

[0041] like Figure 1-2 - As shown in 3-4, the sheet metal line drawing instrument includes a pair of positioning clamps 200, a screw set installed between the pair of positioning clamps, a scale scale 300 installed between the pair of positioning clamps, The support body 400 matched with the scale scale 300, the screw group includes a left-handed screw mandrel 210 and a right-handed screw mandrel 220 of the same size, and the connecting part of the left-handed screw mandrel 210 and the right-handed screw mandrel 220 is provided with a polished rod segment and the polished rod segment is located at At the central position of a pair of positioning clamp seats 200, the outer sleeve of the polished rod section is connected with a grooved bearing 420, and the groove of the grooved bearing 420 is a middle positioning groove 422, and the middle dividing positioning groove 422 is located in the center between the pair of positioning clamp seats. At the branching position, the inner r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com