Fine finishing method for high-quality peanut oil

A peanut oil, high-quality technology, applied in the direction of fat oil/fat refining, chemical instruments and methods, fat production, etc., can solve the problems of inability to remove aflatoxin, poor purity of peanut oil, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

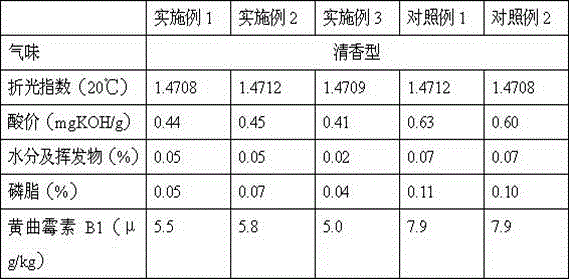

Examples

Example Embodiment

[0023] Example 1

[0024] The first step is to remove the red skin of the peanuts, then dry them at 85°C until the moisture content is less than 5%, and then crush them;

[0025] In the second step, the obtained crushed material is sent to a low-temperature press for pressing, the pressing temperature is 45°C, and the press chamber pressure is 3.0Mpa to obtain crude oil;

[0026] The third step is to filter the crude oil with a 100-mesh screen at low temperature to remove particles;

[0027] In step 4, add bentonite and diatomaceous earth to the filtered crude oil obtained in step 3, and then send it to the ceramic membrane for filtering and degumming. The added amount of bentonite and diatomite are respectively the weight of the filtered crude oil 3%; the molecular weight cut-off of the ceramic membrane is 20000Da, the filtration temperature is 30℃, the filtration pressure is 0.3Mpa, and the average operating flux of the ceramic membrane within 4 hours of operation is 25L / m 2 ·H;

[0...

Example Embodiment

[0032] Example 2

[0033] The first step is to remove the red skin of the peanuts, then dry them at 90°C until the moisture content is less than 5%, and then crush them;

[0034] In the second step, the obtained crushed material is sent to a low-temperature press for pressing, the pressing temperature is 60°C, and the press chamber pressure is 3.5Mpa to obtain crude oil;

[0035] The third step is to filter the crude oil with a 120-mesh screen at low temperature to remove particles;

[0036] In step 4, add bentonite and diatomaceous earth to the filtered crude oil obtained in step 3, and then send it to the ceramic membrane for filtering and degumming. The added amount of bentonite and diatomite are respectively the weight of the filtered crude oil 6%; the molecular weight cut-off of the ceramic membrane is 40000Da, the filtration temperature is 30℃, the filtration pressure is 0.5Mpa, and the average operating flux of the ceramic membrane within 4 hours of operation is 22L / m 2 ·H;

[0...

Example Embodiment

[0041] Example 3

[0042] The first step is to remove the red skin of the peanuts, then dry them at 85°C until the moisture content is less than 5%, and then crush them;

[0043] In the second step, the obtained crushed material is sent to a low-temperature press for pressing, the pressing temperature is 50°C, and the press chamber pressure is 3.2Mpa to obtain crude oil;

[0044] The third step is to filter the crude oil with a 110-mesh screen at low temperature to remove particles;

[0045] In step 4, add bentonite and diatomaceous earth to the filtered crude oil obtained in step 3, and then send it to the ceramic membrane for filtering and degumming. The added amount of bentonite and diatomite are respectively the weight of the filtered crude oil 5%; The molecular weight cut-off of the ceramic membrane is 30000Da, the filtration temperature is 30℃, the filtration pressure is 0.4Mpa, and the average operating flux of the ceramic membrane within 4 hours of operation is 28L / m 2 ·H;

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mwco | aaaaa | aaaaa |

| Mwco | aaaaa | aaaaa |

| Mwco | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap