Replaceable energy-dissipating connection components for beam-to-column connections in fabricated concrete frames

A beam-column connection and component connection technology, applied in building components, protective buildings/shelters, building types, etc., can solve the problem of weakened ability to withstand loads and effects, loss of people's lives and properties, and reduced structural safety, etc. problems, to achieve the effect of simple repair, small maintenance scope and good energy consumption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

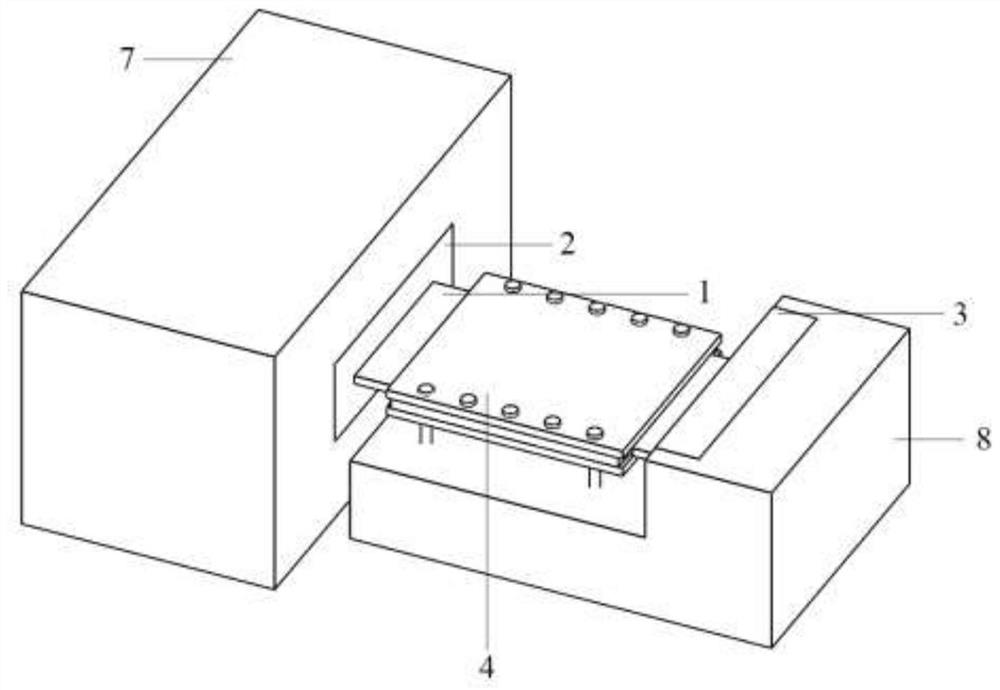

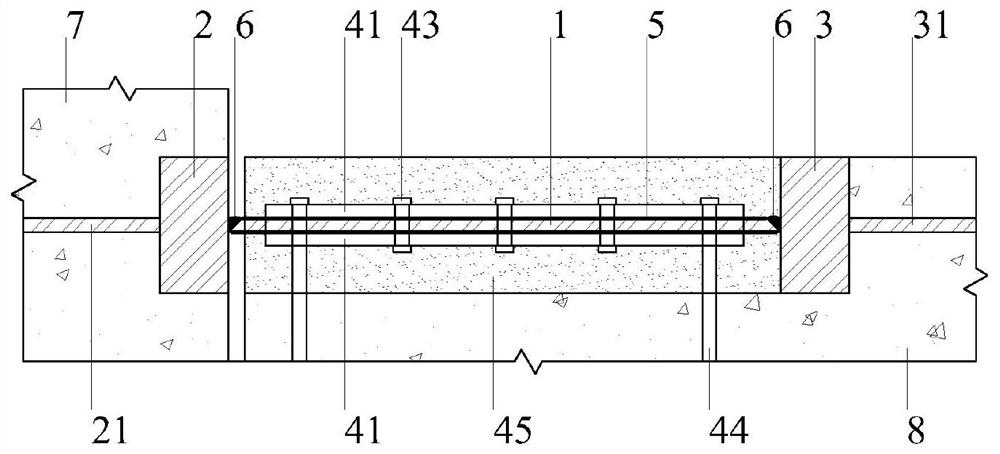

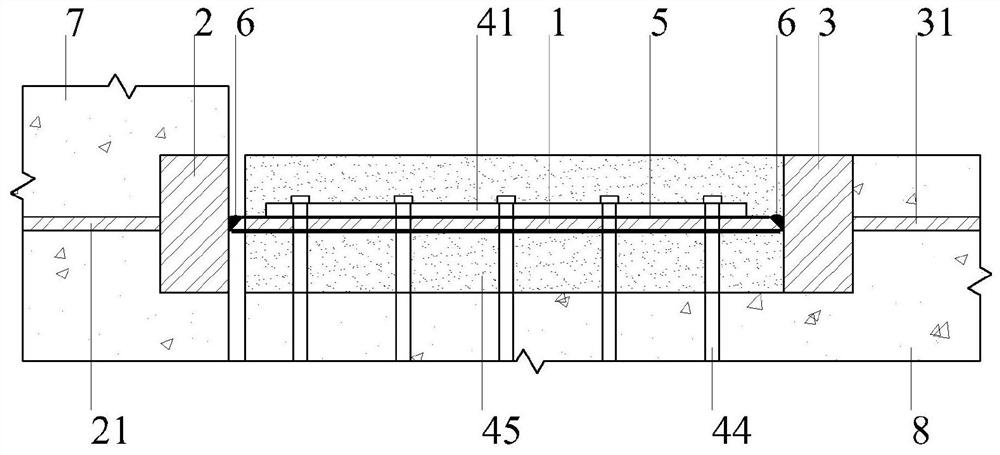

[0038] The specific implementation manner of the present invention will be described below by taking a possible embodiment of the present invention as an example.

[0039] The replaceable energy-dissipating connection assembly proposed by the present invention for the beam-to-column connection of the prefabricated concrete frame will be installed on the left end and / or right end of the beam, and on the upper side and / or lower side of the beam end. In this manual, installation on the upper side of the left end of the beam is taken as an example. When using this example, the left side of the beam is the column, and the column area within the beam height range is the column node area.

[0040] 1) Prefabricated components

[0041] In the component prefabrication stage, the anchor block 2 in the column is pre-embedded at the corresponding position connected in the node area of the column, and its edge extends to the concrete surface of the column. The center of the anchor block ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com