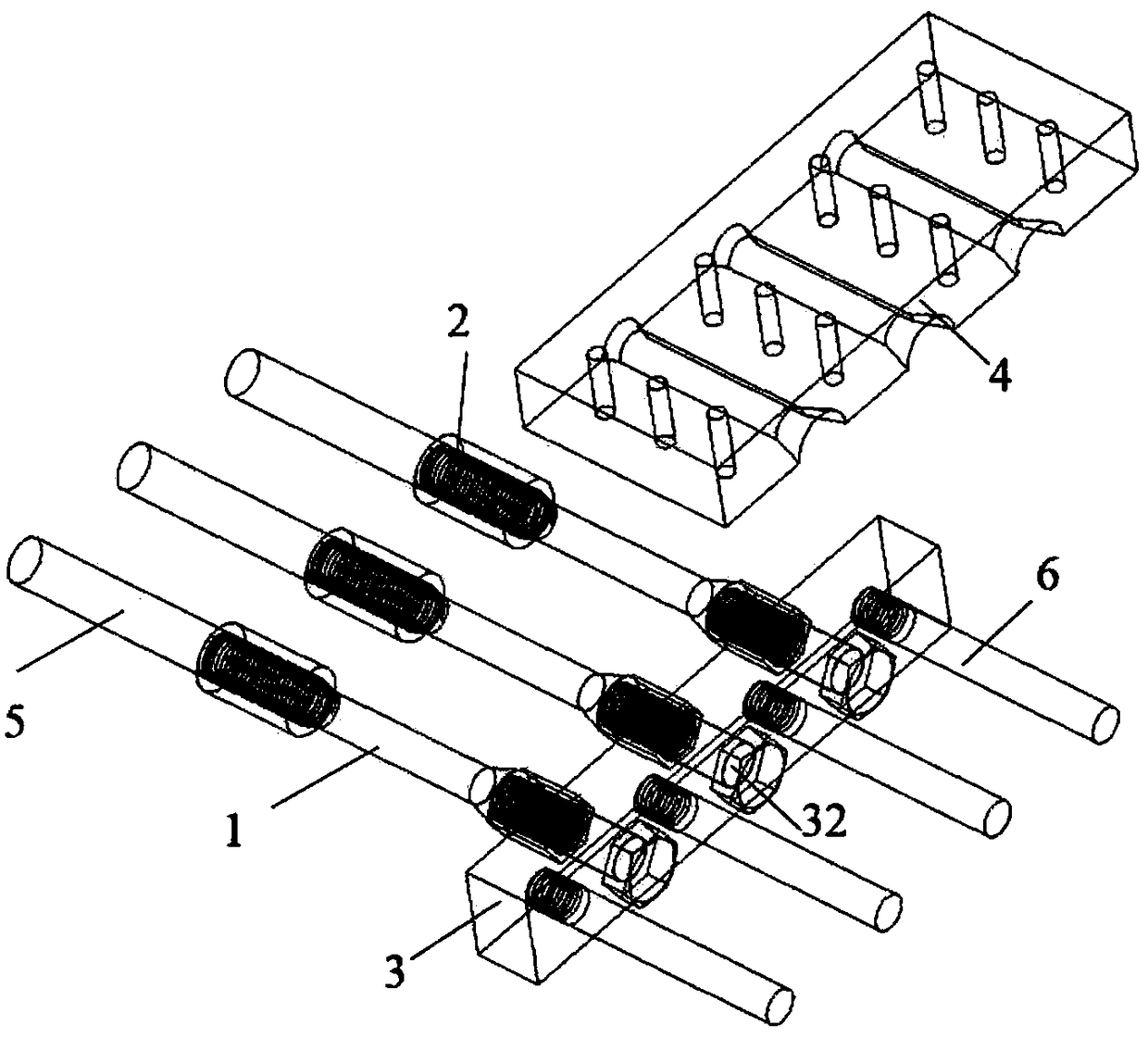

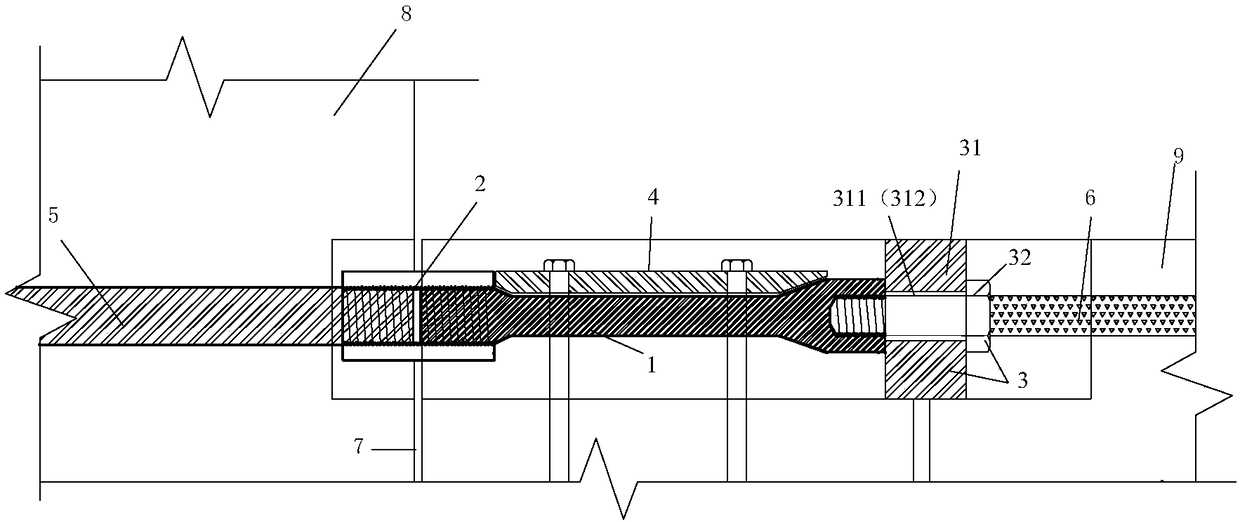

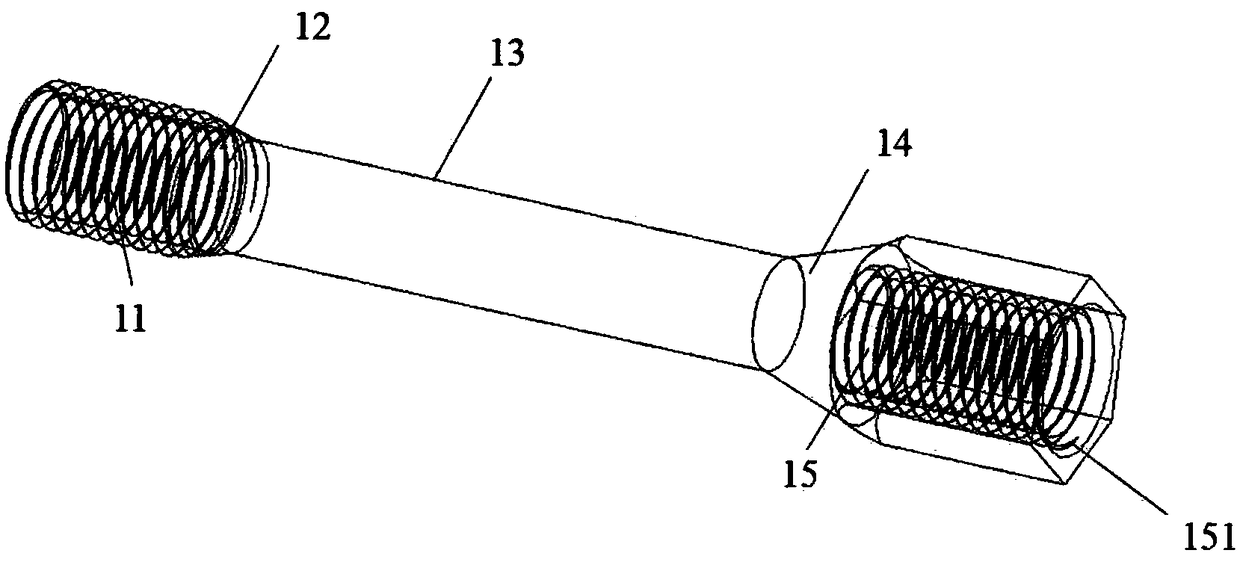

Replaceable energy-dissipating connection components for beam-to-column connections of fabricated frames

A beam-column connection and component connection technology, which is applied to building components, protected buildings/shelters, building types, etc., can solve problems such as replacement and damage to energy-consuming parts, and achieve easy repair, good energy-dissipating performance, and convenient The effect of production and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

[0038] The technical problems addressed by the present invention are as follows:

[0039] 1) The structure of the connecting nodes is the key to the seismic performance of the prefabricated concrete frame structure. The components of the prefabricated concrete structure are generally joined at the joints, so that the performance of the connection is particularly important in the prefabricated concrete structure. The connection nodes are the necessary channels for the internal force transmission between components. Under strong earthquakes, the internal force borne by the beam-column joint connection is relatively large, so plastic deformation is more likely to occur. After the accumulation of plastic damage, it is easy to fail and fracture, resulting in the loss of structural integrity.

[0040] 2) The connection construction of joints is a key...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com