A Topology Optimization Method for Inner Sequence Multiphase Materials

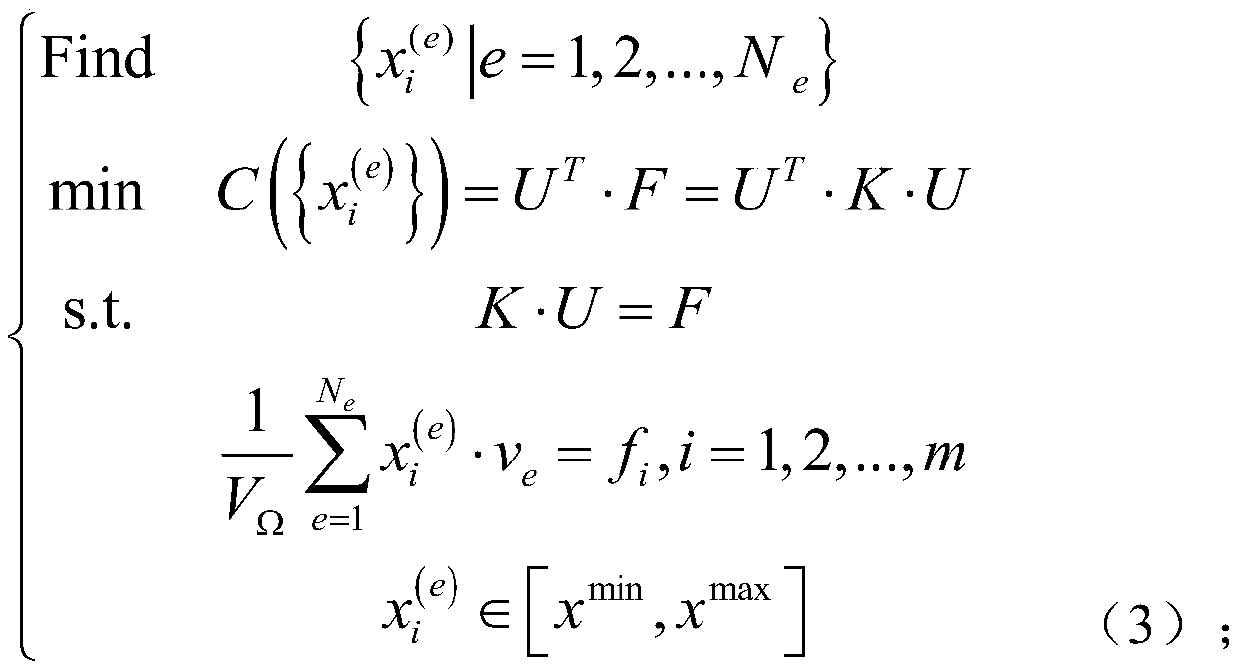

A multi-phase material and topology optimization technology, applied in the field of multi-phase materials, can solve the problems of difficult convergence and high nonlinearity of the multi-phase material optimization model, and achieve the effects of easy convergence, shortening product design cycle, and reducing research and development costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The present invention will be described in detail below in combination with specific embodiments.

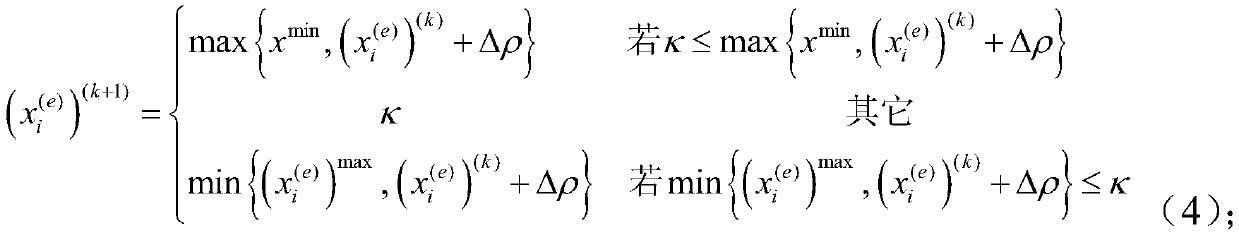

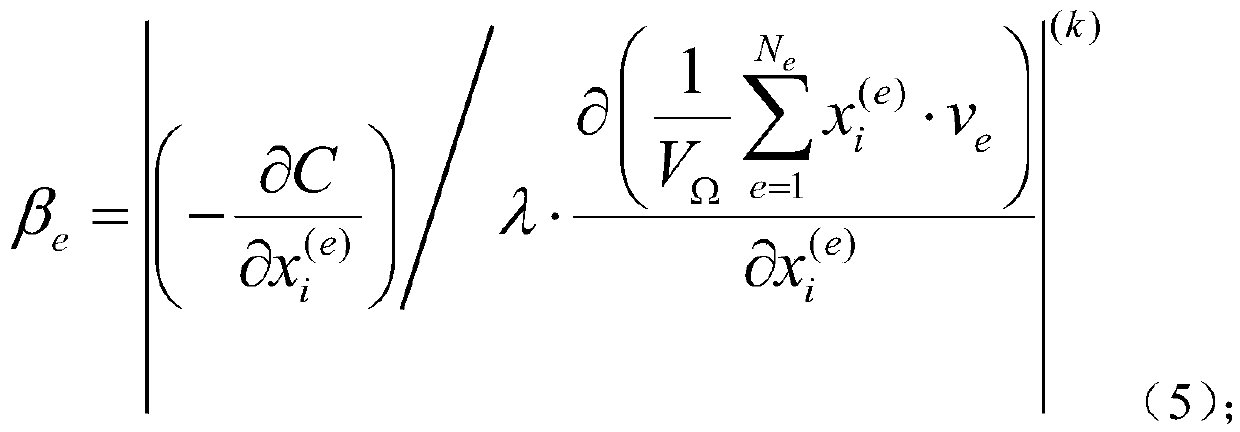

[0061] The principle of an inner sequence multiphase material topology optimization method of the present invention is: add an inner loop inside the optimization loop, and optimize each phase material in turn in the inner loop, and then use the optimized result as the next outer loop. The initial value of each design variable in the loop approaches the optimal result in the continuous outer loop.

[0062] The present invention is a method for topology optimization of internal sequence multiphase materials, which is specifically implemented according to the following steps:

[0063] Step 1. Establish the finite element model of the design domain, initialize the parameters in the algorithm, arrange the materials in descending order according to the modulus, and make the outer iteration number N out = 1, the inner iteration number i = 1, specifically implemented according t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com