Display module structure and manufacturing method of display module

A technology of module structure and display screen, applied in the direction of identification devices, instruments, etc., can solve the problems of poor consistency of LED display modules, achieve the effect of improving brightness consistency and removing edge defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

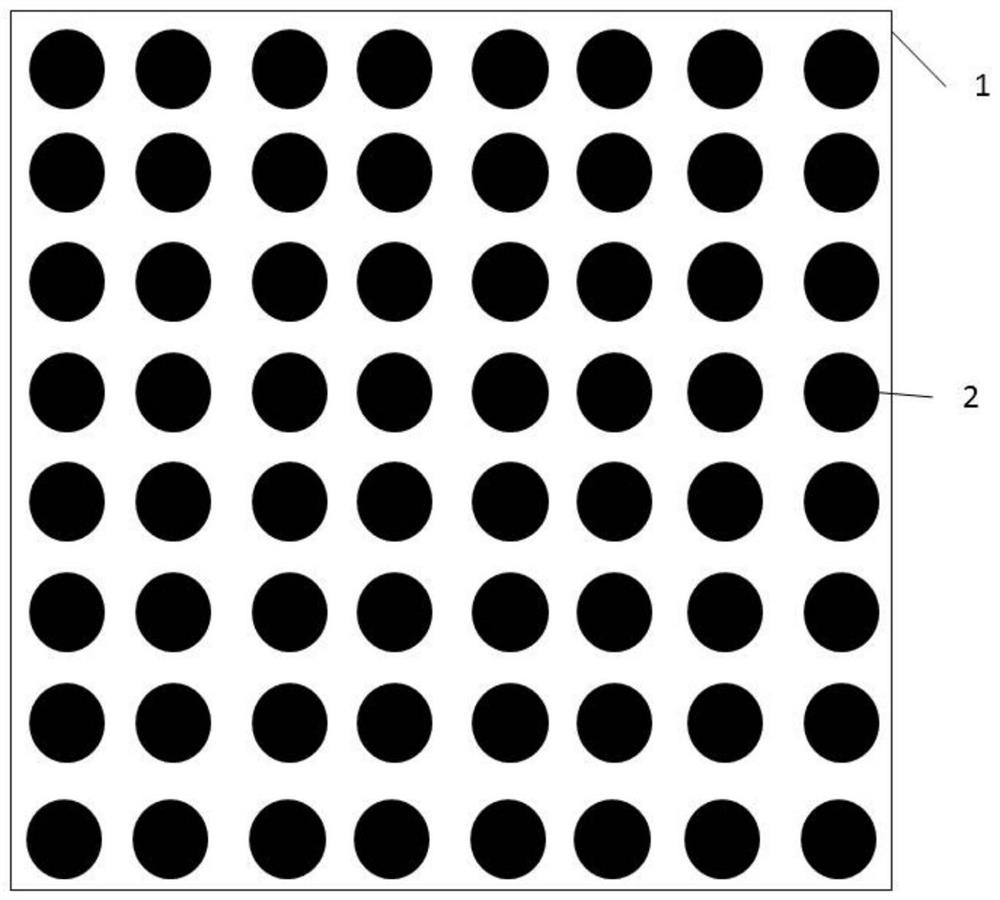

[0042] In order to solve the above problems, the present invention provides an LED display screen module structure, such as Figure 5 shown.

[0043] Figure 5A top view of the LED display screen module structure 500 according to the first embodiment of the present invention is shown. The LED display screen module structure 500 includes a frame body 501 fixed on the LED circuit board. The frame body 501 is provided with N×M hole arrays arranged regularly. Although in Figure 5 The holes shown in are all cylindrical holes, however, those skilled in the art should realize that the shape of the holes is not limited to cylindrical. For example, the hole may be in the shape of an ellipse cylinder, or the hole may also be in the shape of a bowl, that is, the cross-sectional area of the portion in contact with the LED circuit board is smaller than the cross-sectional area of the external opening portion.

[0044] The LED pixel unit 502 can be arranged in the hole of the fram...

Embodiment 2

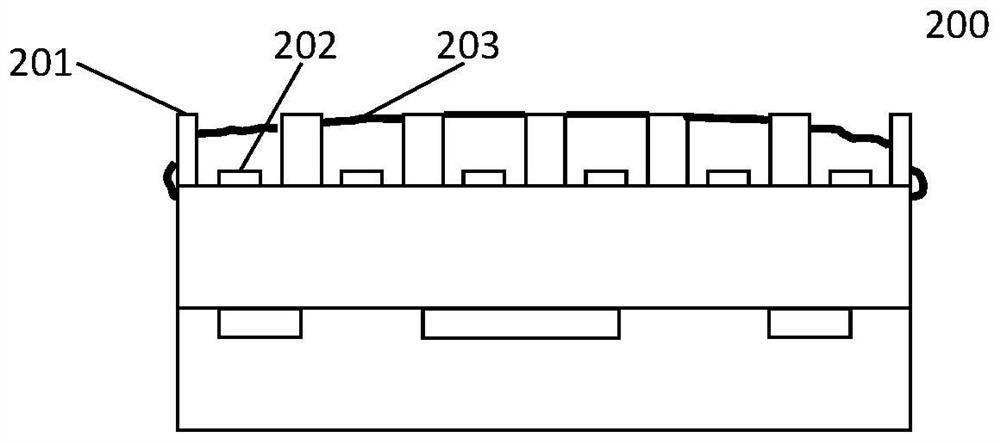

[0051] In order to further improve the consistency of the sealing surface of each hole 503 in the LED display module, the second embodiment of the present invention provides an LED display module structure, such as Image 6 shown.

[0052] Image 6 A top view of the LED display screen module structure 600 according to the second embodiment of the present invention is shown. The LED display screen module structure 600 includes a frame body 601 fixed on the LED circuit board. The frame body 601 is provided with N×M hole arrays arranged regularly. Although in Image 6 The holes shown in are all cylindrical holes, however, those skilled in the art should realize that the shape of the holes is not limited to cylindrical.

[0053] The holes in the frame body 601 can be divided into upper and lower n rows and left and right m columns of edge holes 603 (n, m are integers greater than 1) (hollow holes) at the outermost side of the frame body and edge holes 603 Internal hole 604 (s...

Embodiment 3

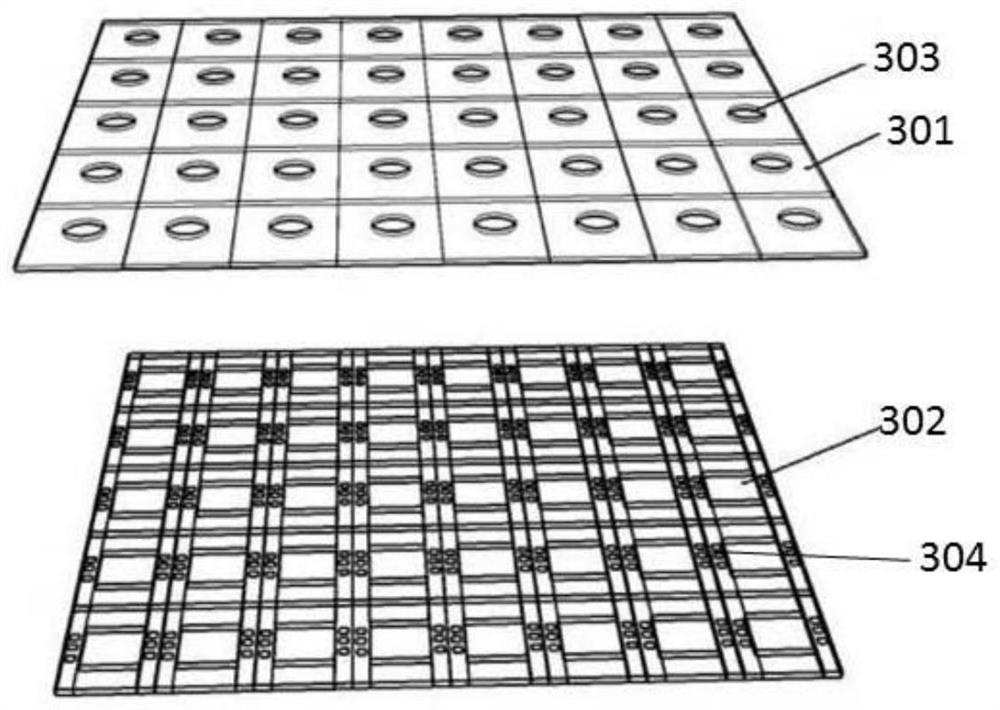

[0060] Figure 7 It is a top view of the LED display screen module structure 700 according to the third embodiment of the present invention. The LED display screen module structure 700 includes a frame body 701 fixed on the LED circuit board. The frame body 701 is provided with N×M hole arrays arranged regularly and an osmotic pressure balance structure 703 arranged around the hole array. The LED pixel unit 702 can be arranged in the hole of the frame body 701 .

[0061] and Figure 5 and Image 6 The difference of the illustrated embodiment is that the osmotic pressure balancing structure 703 is a rectangular strip disposed at the peripheral edge of the frame body 701 instead of an edge hole.

[0062] After the sealant is poured, the LED display module structure is cured and dried to cure the sealant. Then, through a cutting process, the osmotic pressure balance structure 703 is removed.

[0063] In the actual manufacturing process, the actual size and shape of the osmo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com