Feed premixing apparatus

A pre-mixing and feed technology, applied in feed, mixers, mixers with rotary stirring devices, etc., can solve the problems of mixing dead corners, poor mixing effect at corners, poor mixing effect, etc., to avoid mixing dead ends, The effect of feed product quality and quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

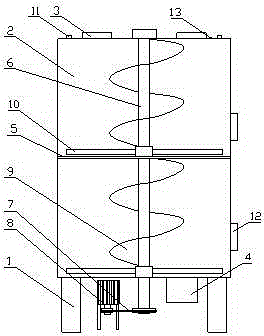

[0013] Such as figure 1 As shown, a preferred embodiment of the present invention: a feed premixing device, comprising a frame 1, a mixing bucket 2 arranged on the frame 1, the top of the mixing bucket 2 is evenly provided with at least two feeding holes 3, Its bottom is provided with at least one discharge hole 4, and the middle position in the mixing barrel 2 is horizontally provided with a middle partition 5, and at least two through holes are arranged on the middle partition 5, and the position of the through holes is the same as The positions of the feed holes at the top of the mixing tank 2 do not overlap, and the middle position of the mixing tank 2 is vertically provided with a stirring shaft 6, and the stirring shaft 6 passes through the middle partition 5, and the upper shaft head passes through the belt The seat bearing is installed on the top of the mixing bucket 2, the lower shaft head of the stirring shaft 6 is fixedly connected to the bottom of the mixing bucket...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com