Method for milling ball grooves and lead angles of ball cage shells

A technology of fairways and cages, which is applied in the fields of fairways and guide angles of milling ball cage shells, can solve the problems of wasting manpower and financial costs, and achieve the effects of preventing dust falling, convenient installation and saving human resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

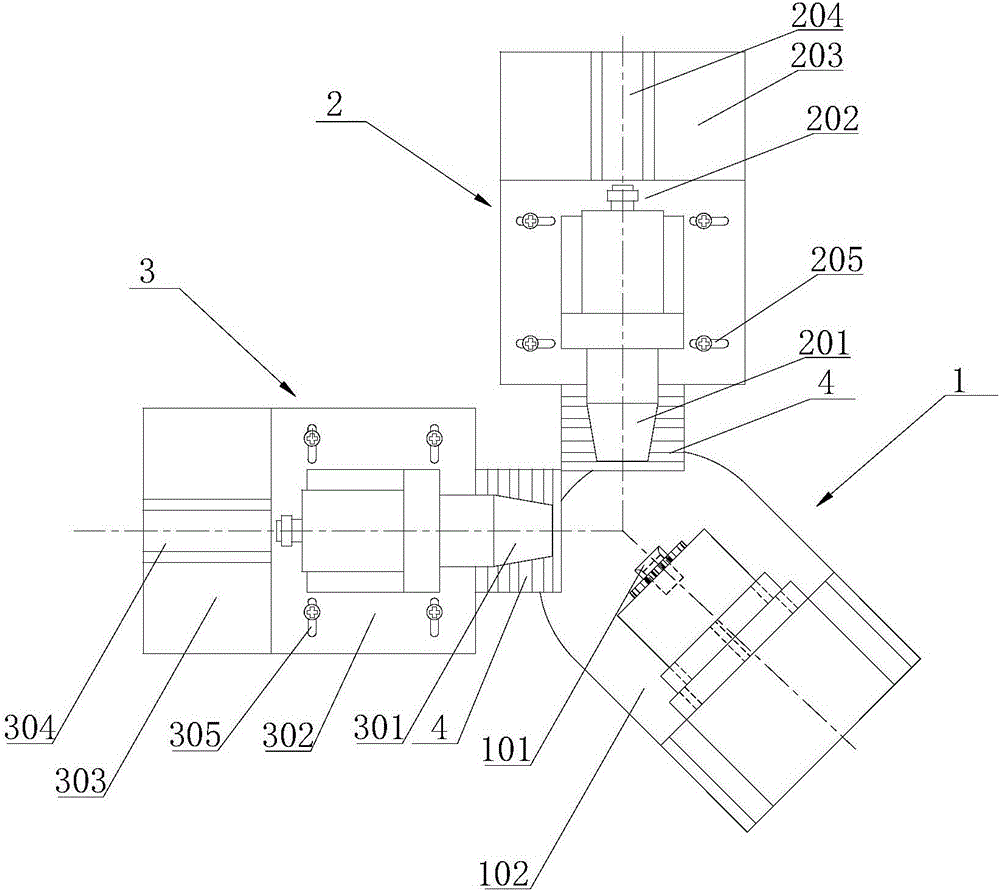

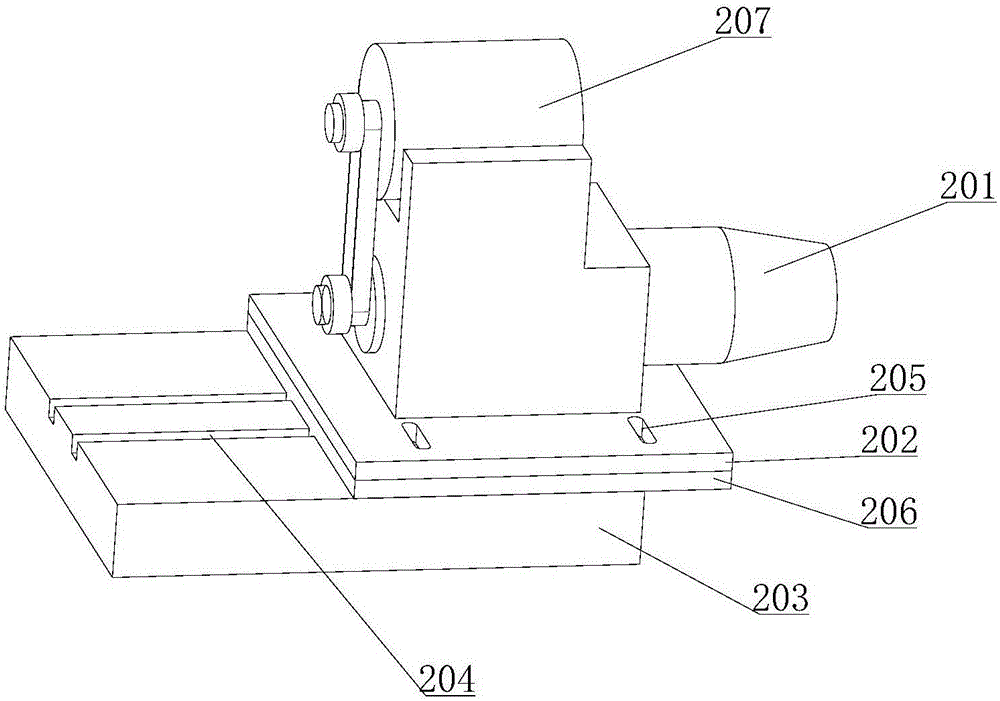

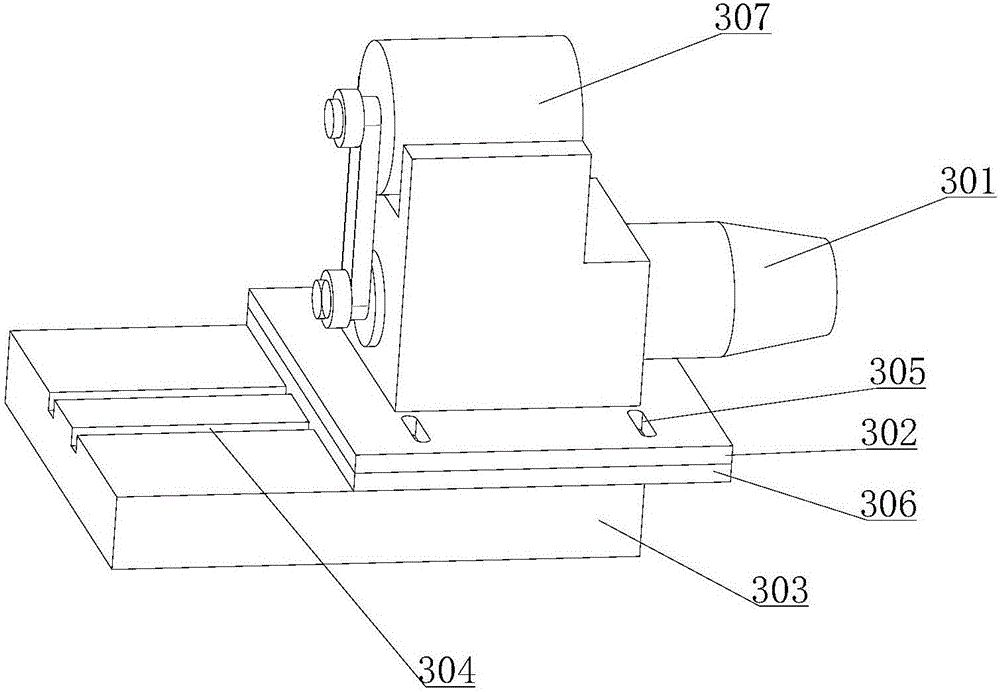

[0044] Such as Figure 1-4 As shown, a method for milling the ballway and chamfer of the ball cage shell includes a fixed part 1, a milling part 2, and a chamfering part 3. The fixed part includes a clamping part 101, a first lower base 102, and a first driving device. 103 : the first driving device 103 drives the clamping part 101 to rotate on the first lower base 102 . The clamping part 101 clamps the bell-shaped shell of the ball cage and protrudes in the horizontal direction; The chamfering component includes a chamfering base 303 and a chamfering jig 301 , and the chamfering jig 301 is arranged above the chamfering base 303 . When the clamping part 101 rotates on the first lower base 102 and reaches the first station, the axial direction of the clamping part 101 is parallel to the axial direction of the ballway clamp 201, and the clamping part 101 rotates on the first lower base 102 to reach the second station. During the working position, the axial direction of the cla...

Embodiment 2

[0063] Such as Figure 1-4 As shown, a method for milling the ballway and chamfer of the ball cage shell includes a fixed part 1, a milling part 2, and a chamfering part 3. The fixed part includes a clamping part 101, a first lower base 102, and a first driving device. 103 : the first driving device 103 drives the clamping part 101 to rotate on the first lower base 102 . The clamping part 101 clamps the bell-shaped shell of the ball cage and protrudes in the horizontal direction; The chamfering component includes a chamfering base 303 and a chamfering jig 301 , and the chamfering jig 301 is arranged above the chamfering base 303 . When the clamping part 101 rotates on the first lower base 102 and reaches the first station, the axial direction of the clamping part 101 is parallel to the axial direction of the ballway clamp 201, and the clamping part 101 rotates on the first lower base 102 to reach the second station. During the working position, the axial direction of the cla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com