Automatic feeding, cutting-off and conveying equipment for cloth strips

A technology of automatic feeding and conveying equipment, which is applied in the cutting of textile materials, textiles and papermaking, metal processing, etc. It can solve the problems that cannot guarantee the accuracy and smoothness of the cut cloth, heavy workload, and low work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

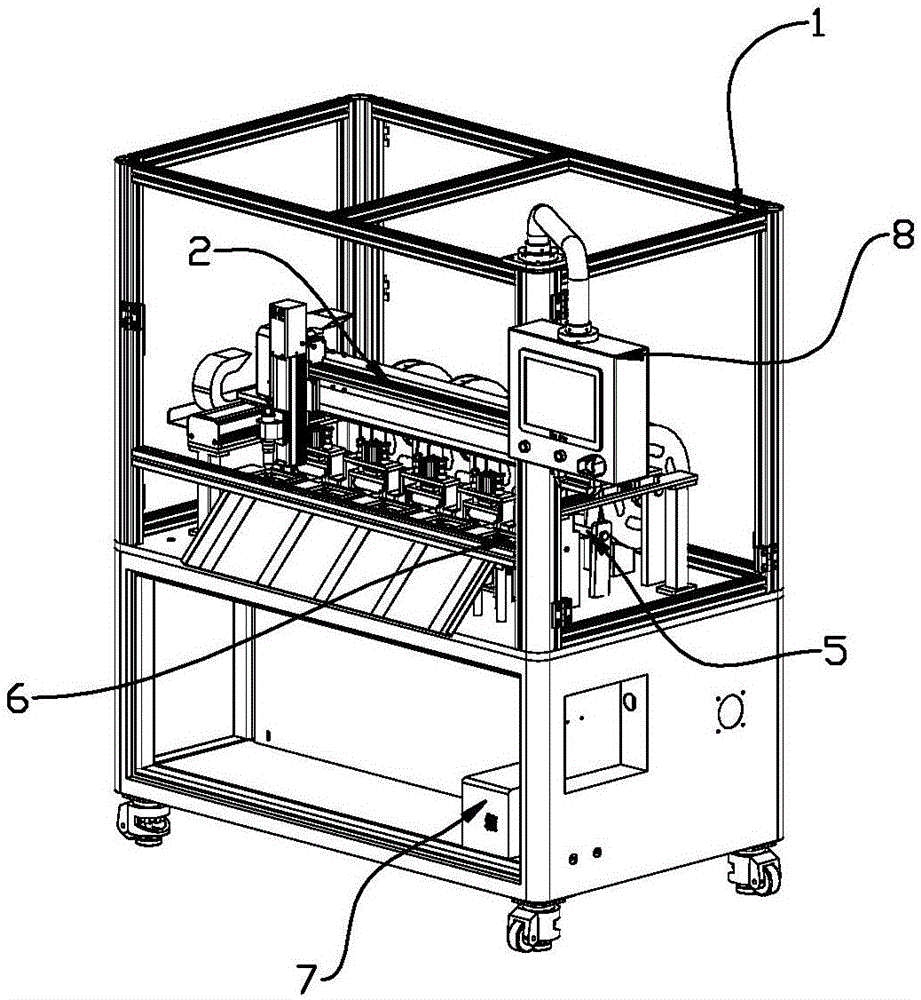

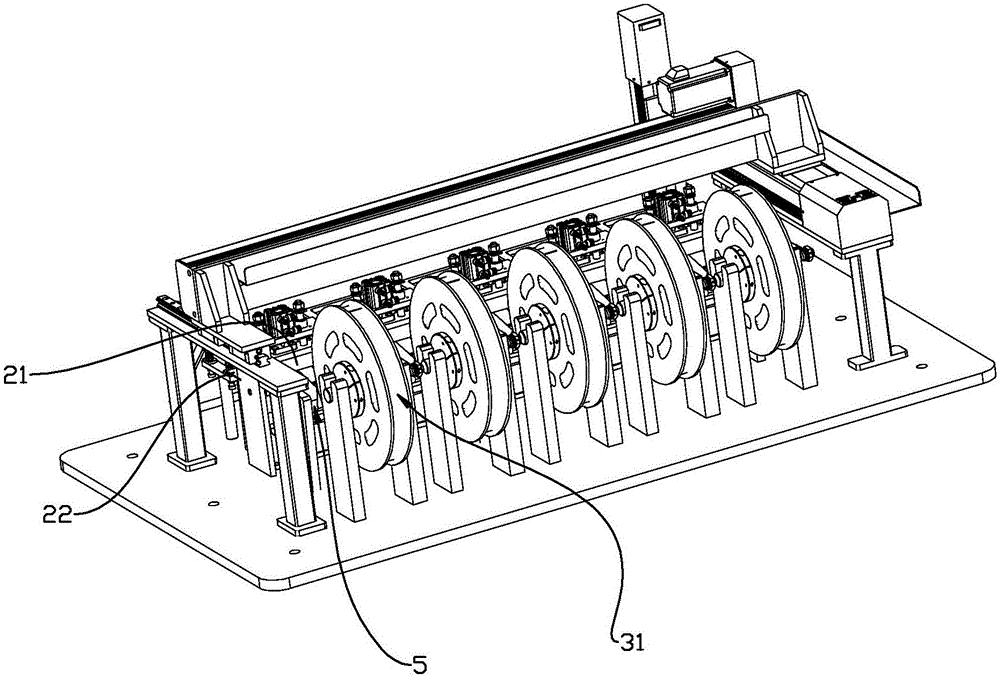

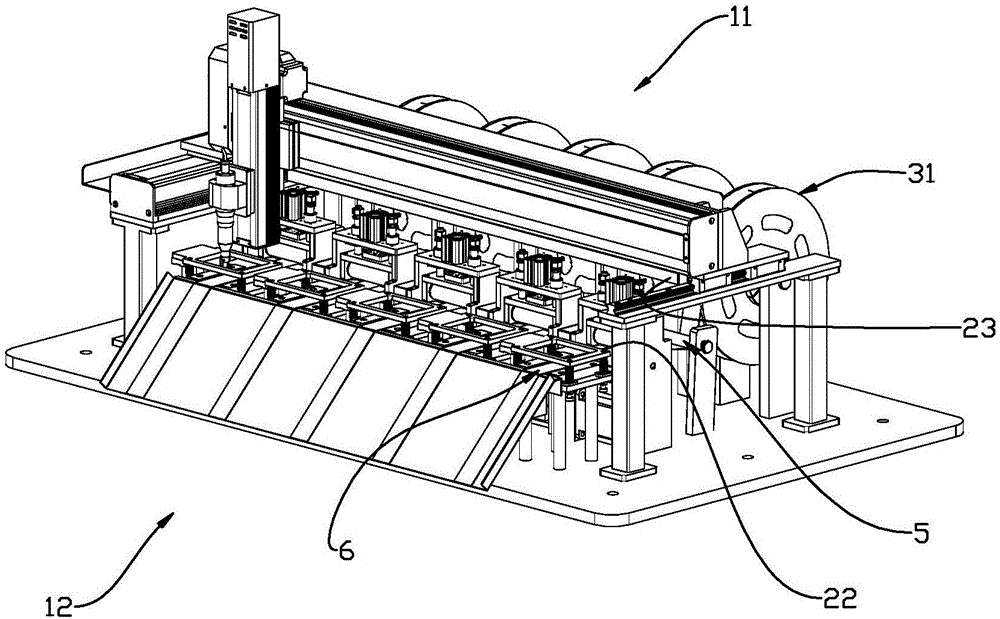

[0018] Specific embodiments of the present invention such as Figure 1-4 Shown is the automatic feeding and cutting conveying equipment for cloth strips, including a frame 1, which is provided with a feed end 11, a discharge end 12, and a cutting device 2 installed between the feed end 11 and the discharge end 12 , the feed end 11 is equipped with a cloth reel 31, a feed conveying guide roller 5 is provided between the cloth reel 31 and the cutting device 2, and a discharge conveyor belt 6 is provided between the cutting device 2 and the discharge end 12. The frame 1 is also provided with a control box 7 and a display screen 8. The control box 7 is installed in the cabinet below the frame 1. The cutting data can be displayed on the display screen 8. The feed end 11 is equipped with mounting seats distributed side by side, and the cloth The reel 31 is erected on the mounting seat through the connecting shaft 34. The mounting seat includes mounting plates 32 distributed on both ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com