Cutting machine with network communication-based remote automatic measurement device

A technology of automatic measurement and network communication, applied in the field of cutting machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

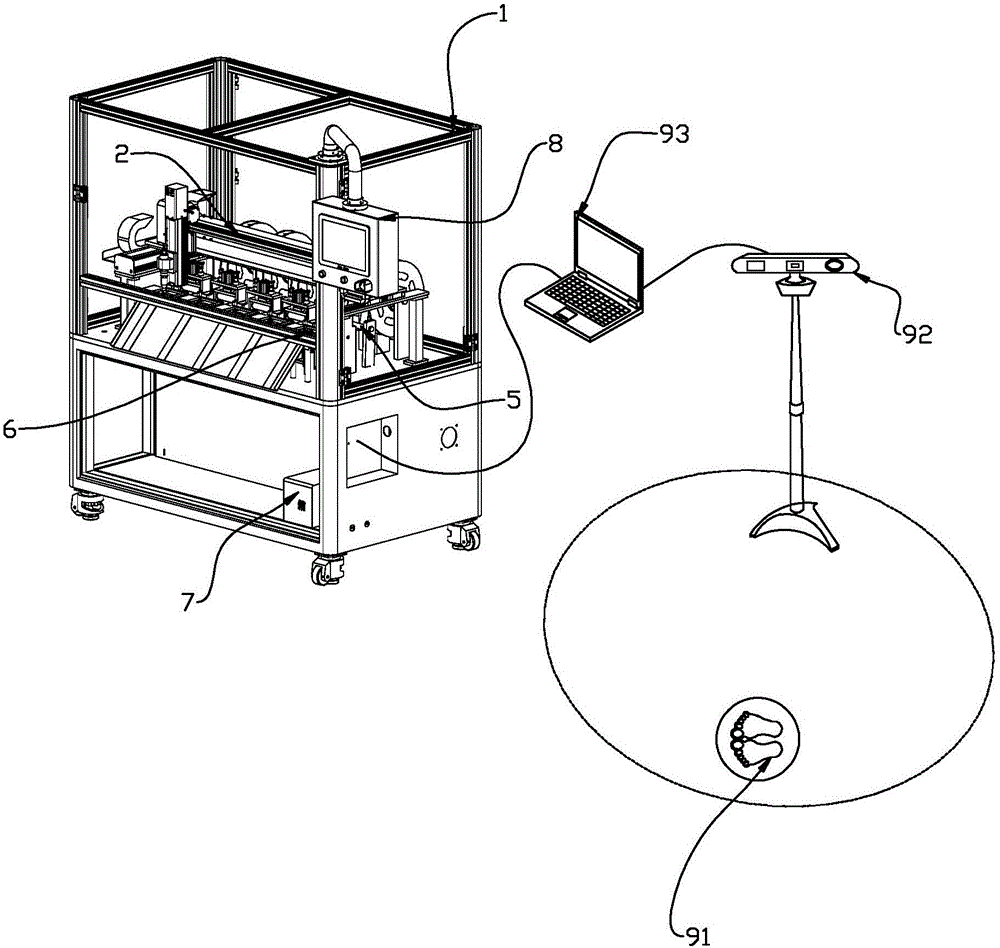

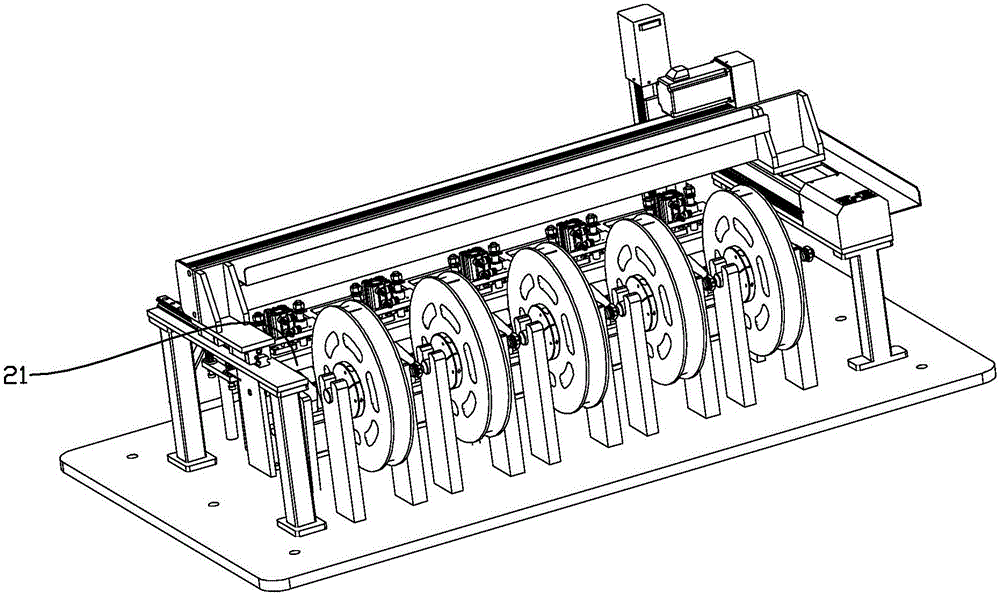

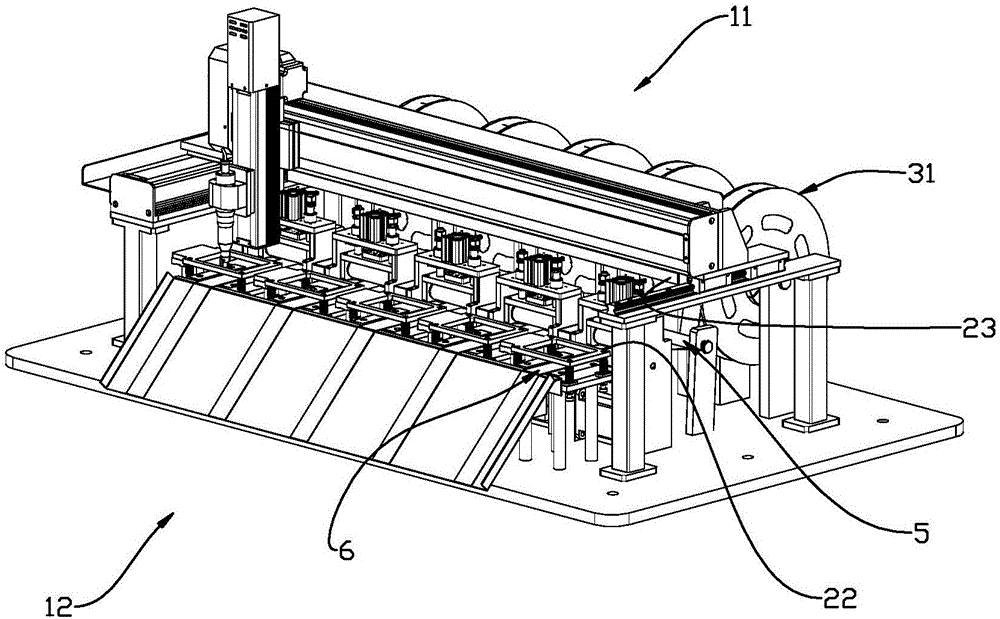

[0023] Specific embodiments of the present invention such as Figure 1-8 Shown is a cutting machine with a remote automatic measuring device based on network communication, which includes a human body size measuring device and a cutting device. The human body size measuring device includes a pedal platform 91 for the human body to stand on, a rotary driver that drives the pedal platform 91 to rotate, Portrait scanner 92, computer 93, computer 93 is connected with camera scanner through network communication (RS232 agreement), the output end of computer 93 is connected with cutting device, and cutting device comprises frame 1, is provided with feeding material on frame 1 End 11, discharge end 12, cutting device 2 installed between the feed end 11 and the discharge end 12, the feed end 11 is equipped with a cloth reel 31, between the cloth reel 31 and the cutting device 2 is provided Material conveying guide roller 5, be provided with discharge conveyor belt 6 between cutting de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com