A high-frequency vibrating table for a bracket type cement component

A high-frequency vibration, bracket-type technology, used in ceramic molding machines, manufacturing tools, etc., can solve the problems of increasing vibration effect, vibration force consumption, reducing vibration effect, etc., and achieve the effect of increasing vibration effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

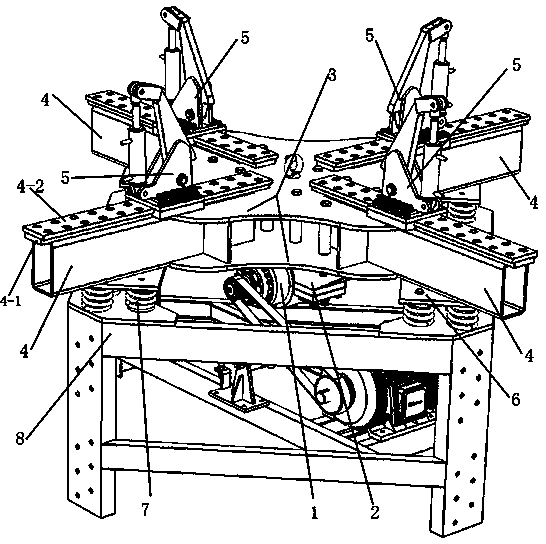

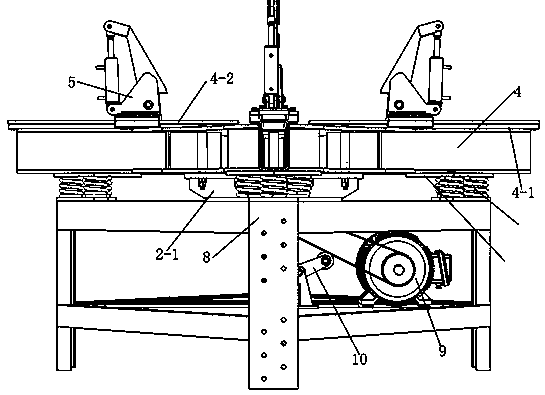

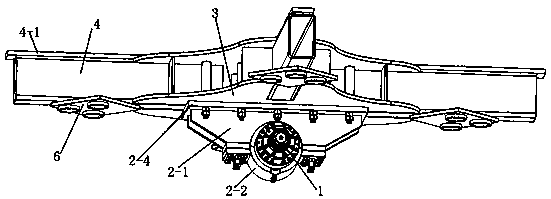

[0013] Such as Figure 1-3 As shown, a bracket-type cement component high-frequency vibrating table includes a vibrator 1, a fixed sleeve 2 is sleeved on the outer end surface of the vibrator 1, a vibrating table 3 is installed on the top of the fixed sleeve 2, and the vibrating table 3 It is used to place the cement component mold to be vibrated that is not fixedly connected and movable on the vibrating table.

[0014] In order to further increase the stability of the mold of the cement component to be vibrated, four sets of extension brackets 4 are installed on the side of the vibrating table in this embodiment, and four sets of extension-type locking seats 5 corresponding to it are slidably installed on the four sets of extension brackets 4 , the four sets of extended locking seats 5 are regularly located on the outer end face of the cement component mold to be vibrated, and the cement component mold to be vibrated is locked and fixed on the vibrating table 3;

[0015] A b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com