Automatic pouring template oil coating device

A technology of oiling device and template, applied in the direction of mold, ceramic molding machine, manufacturing tool, etc., to achieve the effect of easy setting, cost saving and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below by means of specific embodiments:

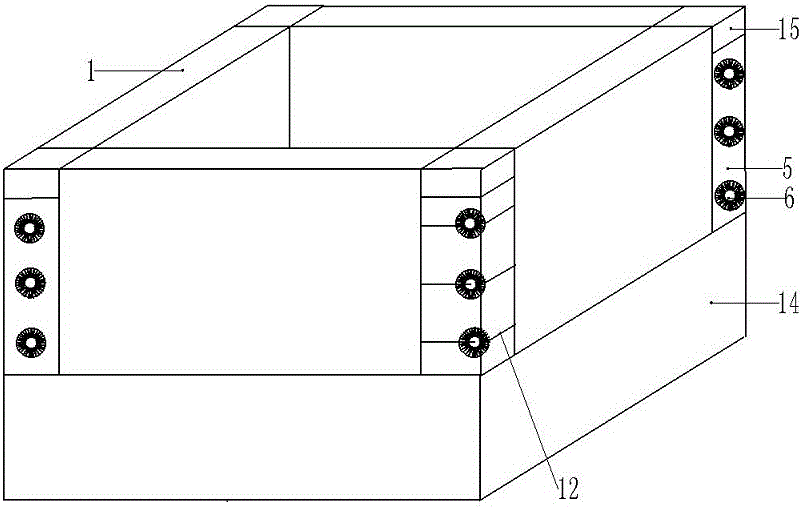

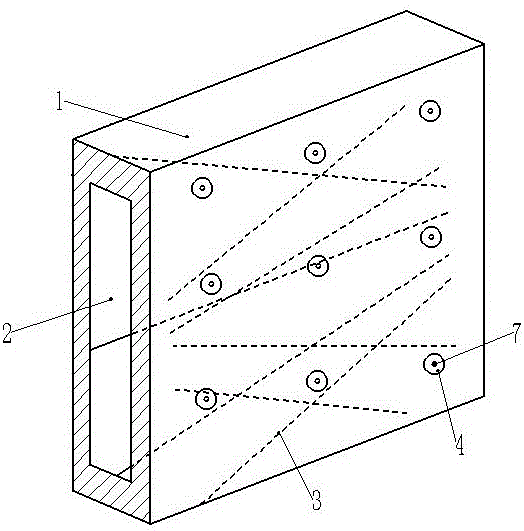

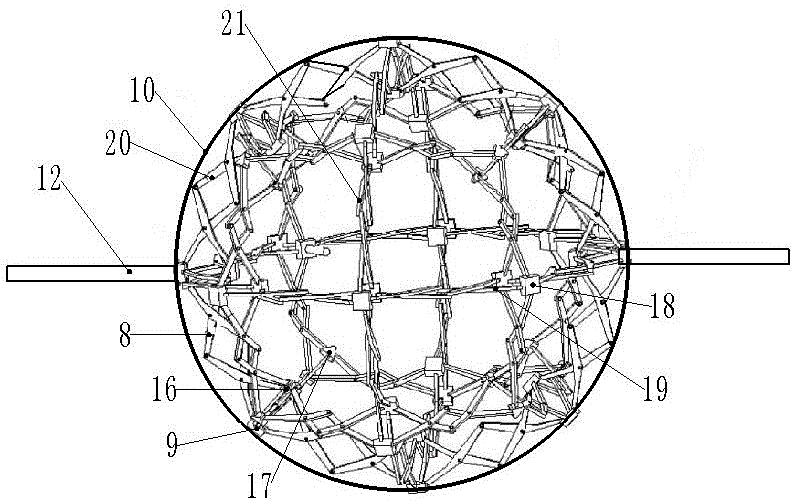

[0024] The reference signs in the drawings of the description include: pouring template 1, hollow layer 2, mold oil channel 3, through hole 4, built-in cavity 5, mold oil ball 6, atomizing nozzle 7, telescopic ball 8, outer layer connection point 9 , elastic ball 10, pinhole 11, pull rod 12, oil outlet hole 13, oil sump 14, chamber cover 15, inner connection point 16, three-link component group 17, four-link component group 18, horizontal ring 19, front Ring 20, side ring 21, triangular rod seat 22, connecting rod 23 in the three-link member group, quadrilateral rod seat 24, connecting rod 25 in the four-bar member group.

[0025] The embodiment is basically as figure 1 and figure 2 Shown: pouring formwork automatic oiling device, including a box-shaped casting mold spliced by five pouring formworks 1, each pouring formwork 1 is provided with a hollow layer 2, and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com